100-120 t/h Limestone Crushing Production Line Solutions

In the aggregate production and mining sectors, limestone, as a crucial basic raw material, requires efficient and stable crushing for project profitability and sustainable development. A scientifically designed and reliable crushing production line directly determines your return on investment. For limestone crushing plants with a capacity of 100-120 tons per hour, selecting the right equipment and solutions is a core concern for many owners. As a manufacturer of mining crushing equipment with 20 years of professional experience, we understand this well and are committed to providing global customers with comprehensive, high-performance solutions, from single machines to complete production lines.

Overview: Why 100-120 tons/hour?

A capacity design of 100-120 tons per hour represents the golden capacity point for small to medium-sized production. It meets the aggregate needs of most building material production, highway construction, and concrete mixing plants, while achieving an optimal balance between equipment investment, land area, energy consumption, and output. Achieving stable production capacity for medium-hardness, dust-generating limestone requires a mature, wear-resistant, and cost-effective crushing and screening system. Our solution is tailor-made for this purpose, ensuring a smooth production line, excellent output particle shape, and long-term reliable operation.

Our Core Product Advantages

1. High Efficiency and Energy Saving, Cost Leadership: Core crushing equipment (such as jaw crushers, impact crushers, or cone crushers) utilizes optimized chamber shapes and higher-speed spindles, achieving higher throughput and better crushing ratios at the same power, significantly reducing energy consumption per ton of material.

2. Robust and Durable, Easy Maintenance: Key components are made of high-strength alloy materials and advanced manufacturing processes, with special hardening treatment for the abrasiveness of limestone, greatly extending the life of wearing parts. Modular design makes daily inspection, maintenance, and parts replacement faster, reducing downtime.

3. Excellent Finished Product, Controllable Particle Shape: Equipped with multi-layer vibrating screens and fine crushing equipment, the output specifications can be flexibly adjusted (e.g., 0-5mm, 5-10mm, 10-31.5mm, etc.), producing high-quality aggregates with cubic particle shapes and low needle-like and flaky content, meeting the needs of high-standard commercial concrete and dry-mixed mortar.

4. Environmentally Friendly and Intelligent, Stable Operation: The fully enclosed design is equipped with a high-efficiency pulse dust removal system to effectively control dust emission. The intelligent electrical control system can monitor the equipment's operating status, realize fault early warning and remote diagnosis, and ensure continuous and stable operation of the production line.

5. Customizable for All Scenarios, Flexible Layout: We offer a variety of configuration options from fixed to mobile. Fixed production lines are suitable for long-term, intensive production; mobile crushing stations (wheel-mounted or tracked) are suitable for scenarios with dispersed mining areas and the need for relocation, offering extremely high flexibility.

Typical Application Scenarios

• Building Material Aggregate Production: Providing high-quality coarse and fine aggregates for commercial concrete mixing plants, precast component plants, and brick and tile factories.

• Highway/Infrastructure Construction: Production of crushed stone of various specifications required for highway base courses, subbase courses, and asphalt concrete.

• Cement Production Raw Material Preparation: Crushing large pieces of limestone to the particle size required for grinding.

• Metallurgical Flux Preparation: Providing limestone flux for steel mills.

• Environmental Desulfurization Agent Production: Preparing limestone powder for power plant flue gas desulfurization.

Global Project Cases

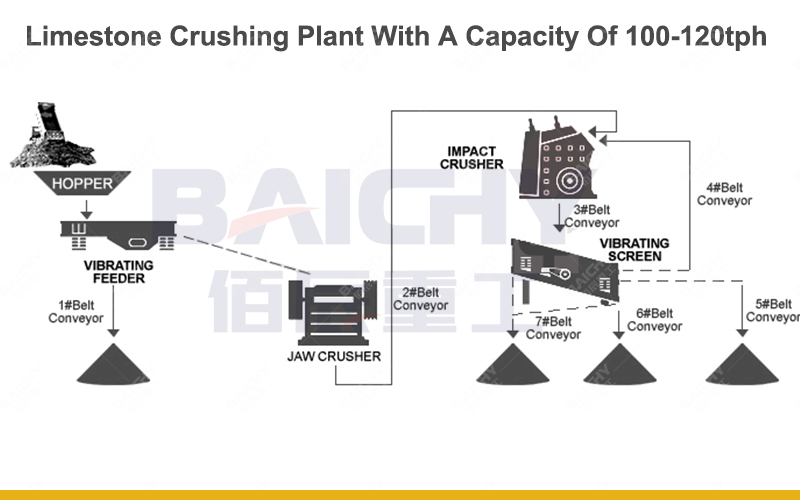

We have successfully delivered numerous limestone crushing projects worldwide. For example, at the base of a large building materials group in Southeast Asia, we designed and built a stationary limestone crushing production line with a capacity of 110 tons per hour. This line adopts a classic three-stage process: jaw crusher (primary crushing) + impact crusher (secondary crushing) + circular vibrating screen (screening). Since its commissioning, it has maintained a stable operating rate of over 95%, continuously producing high-quality aggregates of various specifications, fully meeting the client's stringent requirements for capacity, yield, and environmental protection, and has earned high praise from the client.

Frequently Asked Questions (FAQ)

Q: What is the recommended core equipment configuration for a limestone crushing line with a capacity of 100-120 tons per hour?

◦ A: A common high-efficiency configuration is a PE600×900 jaw crusher + PF1214/1315 impact crusher or a jaw crusher + single-cylinder hydraulic cone crusher. Specific selection needs to be based on the maximum particle size of the raw material, finished product requirements, and investment budget.

Q: How long does it take for the entire production line to go from installation to commissioning?

◦ A: For a standard configuration stationary production line, provided the civil engineering foundation is ready, equipment installation, commissioning, and trial operation can usually be completed within 4-8 weeks. Mobile crushing plants are even faster, and can be put into use within a few days.

Q: Do you provide process design and installation guidance?

◦ A: Yes. We provide turnkey full-service support, from site survey, process flow design, equipment selection, to installation guidance, commissioning, and operation training.

Q: How to control dust pollution during the production process?

◦ A: We will design sealed covers at key dust-generating areas such as transfer points and material discharge points, and equip them with high-efficiency baghouse dust collector systems to ensure emissions meet local environmental standards.

Choosing an experienced partner is the first step to project success. With 20 years of technical expertise and global project experience, we are ready to provide you with professional consulting and solutions to help your limestone crushing project operate efficiently and steadily.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.