Building an efficient, stable, and environmentally friendly limestone crushing and screening plant is a core requirement for many sand and gravel aggregate and industrial raw material enterprises.

This article will take a medium-sized production line with an hourly output of 200 tons as an example to deeply analyze its core equipment selection, scientific process flow layout, and key design points, providing authoritative reference for your project planning.

In the sand and gravel aggregate industry, a limestone processing line with an hourly output of 200 tons is a classic "golden scale," which can meet the stable supply needs of large-scale engineering projects while achieving a good balance between investment and operating costs. To build such an efficient production line, the following aspects are crucial:

I. Core Crushing Equipment Selection: Two-Stage Crushing is the Cornerstone

For medium-hardness limestone (Protodyakonov hardness f=8-10), we recommend a two-stage crushing scheme of "jaw crusher + impact crusher" or "jaw crusher + cone crusher."

1. Coarse Crushing – Jaw Crusher: As the "throat" of the production line, it is responsible for processing large pieces of raw stone (particle size up to 500-600mm) from the quarry. Its powerful crushing force and high reliability ensure stable feeding in subsequent processes. For a processing capacity of 200 tons/hour, a model with a feed opening size of approximately 750×1060mm or larger should be selected.

2. Medium and Fine Crushing – Impact Crusher/Cone Crusher: This is crucial in determining the final product particle shape.

◦ Advantages of Impact Crusher: Good finished product particle shape, cubic, and high value. Particularly suitable for producing high-standard aggregates for construction. However, its hammer wear is relatively fast, making it suitable for limestone with low silica content and low abrasiveness.

◦ Advantages of Cone Crusher: Long wear-resistant part life, stable operation, suitable for processing materials with slightly higher hardness or higher abrasiveness. However, the content of needle-like and flaky particles in the finished product may be slightly higher than that of the impact crusher.

II. Scientific and Efficient Process Flow Layout

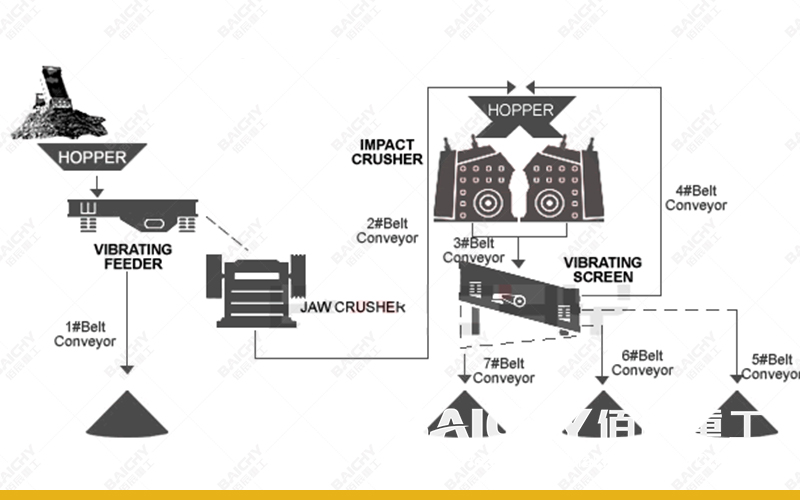

A typical 200t/h limestone crushing and screening process is as follows:

Raw Ore -> [Vibrating Feeder] -> [Jaw Crusher] (Coarse Crushing) -> [Vibrating Screen] (Pre-screening) -> [Impact Crusher/Cone Crusher] (Medium and Fine Crushing) -> [Vibrating Screen] (Grading Screening) -> Finished Product Bin

• Pre-screening: A vibrating screen is installed after coarse crushing. Materials that already meet the particle size requirements (e.g., 0-31.5mm) can be directly screened out and fed into the finished product stockpile, avoiding over-crushing and energy waste in the medium crushing equipment, significantly improving efficiency.

• Closed-loop circulation: The material after medium and fine crushing forms a closed loop with the vibrating screen. Large particles that do not meet the specifications on the screen are returned to the crusher for further crushing until they meet the standards. This design ensures precise control of product particle size and maximizes the utilization rate of the production line.

III. Key Auxiliary Systems: Determining the "Intelligence" and "Emotional Intelligence" of the Production Line

• Dust Removal System: Environmental protection is the lifeline. High-efficiency pulse-jet bag filters must be installed at all dust-generating points, including the feed inlet, crusher inlet and outlet, screening machine, and belt conveyor transfer points, to ensure emissions meet standards.

• Automated Control System: Utilizing PLC central control, the system can monitor equipment operating status, current, temperature, and other parameters in real time, enabling one-button start/stop, fault alarms, and interlocking control, significantly reducing labor costs and improving safety and stability.

An excellent 200-ton/hour limestone production line is not merely a simple collection of equipment, but a systematic engineering project. Precise material analysis, reasonable equipment matching, scientific process design, and reliable environmental protection measures together constitute its core competitiveness. If you are planning to invest in such a project, please contact us for customized technical solutions and quotations.