Imppact Crusher

The high-intensity operations of limestone quarries, selecting a high-efficiency and reliable crushing equipment is crucial to production efficiency. As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing comprehensive solutions for mining clients worldwide.

Today, we provide an in-depth analysis of how the Baichy impact jaw crusher, with a processing capacity of 180 tons/hour, delivers outstanding performance in limestone quarries, helping you achieve your operational goals of cost reduction and efficiency improvement.

| Key Words | Limestone Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

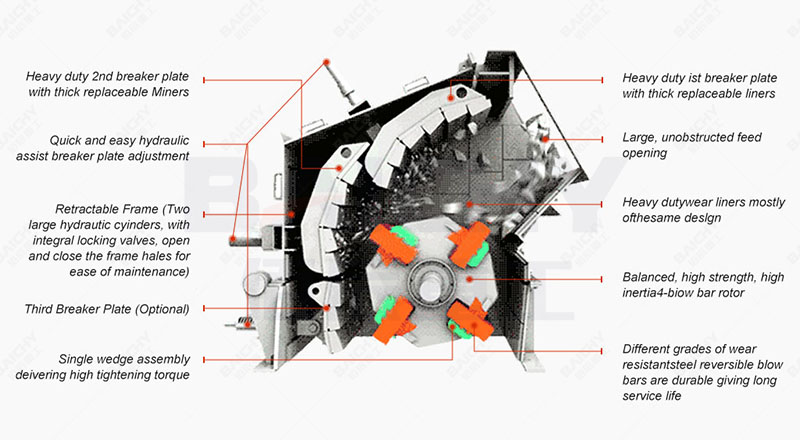

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

The Baichy impact jaw crusher is a multi-functional piece of equipment that combines the stability of a jaw crusher with the high efficiency of an impact crusher. It is specifically designed for processing medium-to-high hardness ores such as limestone, granite, and basalt. It has a maximum feed size of 750mm and an adjustable discharge size within the range of 20-200mm, with a stable hourly capacity of 180 tons, making it an ideal choice for medium to large quarries. Its unique design integrates an advanced hydraulic system and intelligent control technology, ensuring a smooth and efficient crushing process while reducing energy consumption and maintenance costs.

PF Impact Crusher Structure Diagram

Product Advantages

1. High Efficiency and Energy Saving: Optimized crushing chamber design and power matching result in 15%-20% energy savings compared to traditional equipment, significantly increasing production capacity per unit of energy consumption.

2. Robust and Durable: Key components such as the jaw plates are made of high-manganese steel casting, enhanced with heat treatment for improved wear resistance, extending lifespan by 30% and reducing replacement frequency.

3. Intelligent Control: Integrated PLC automation system monitors operating status in real time, supports remote adjustment and fault diagnosis, reducing manual intervention.

4. Environmentally Friendly and Low Noise: The enclosed structure combined with vibration damping design results in operating noise below 75 decibels, and dust emissions meet international environmental standards.

5. Flexible Adaptability: Modular design facilitates transportation and installation, quickly adapting to perse site conditions and accelerating project startup.

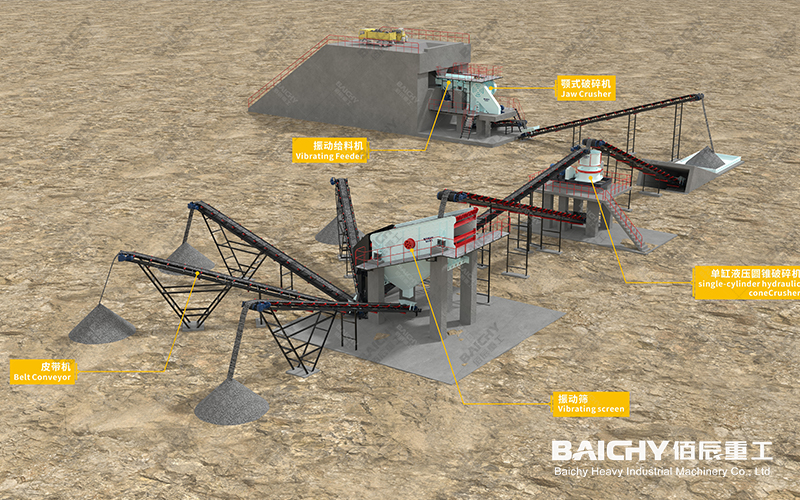

Aggregate crushing plant

Application Scenarios

The Baichy impact jaw crusher is widely used in the primary crushing stage of limestone quarries, suitable for:

• Mining: Processing large limestone raw materials to provide uniformly sized materials for downstream sand making or grinding processes.

• Building Materials Production: Supplying high-quality aggregates to cement, concrete, and asphalt mixing plants, ensuring the strength and stability of building materials.

• Road Construction: Crushed limestone can be directly used for roadbed paving, improving project durability.

• Environmental Recycling: Compatible with construction waste recycling, promoting resource recycling.

Project Case Study: In a large limestone quarry project in Southeast Asia, the client faced challenges such as insufficient capacity and frequent maintenance of existing equipment. We configured a Baichy impact jaw crusher, combined with a vibrating feeder and conveyor belt to form a production line. As a result, the daily processing capacity increased to 2,000 tons, the equipment operated continuously for 6 months without failure, helping the client reduce production costs by 18% and achieve their annual production target ahead of schedule. Client feedback: "This crusher is not only stable and reliable, but its intelligent control system also makes our operation simpler, truly achieving a win-win situation of high efficiency and environmental protection."

FAQ (Frequently Asked Questions):

Q1: Is the equipment suitable for processing limestone with high moisture content?

A: Yes, Baichy impact jaw crushers feature an anti-clogging design and can handle materials with a moisture content below 10%. Customized solutions are available for special operating conditions.

Q2: What is the maintenance cycle?

A: We recommend a routine check every 500 hours. Automatic reminders for critical lubrication points significantly reduce downtime.

Q3: Can it be integrated with existing production lines?

A: Fully compatible. We offer free technical consultation to ensure seamless integration of the equipment with your production system.

Q4: How long is the delivery and installation time?

A: Standard equipment is shipped within 30 days. A professional team will install and commission the equipment on-site, allowing for production within 7 days.

Choosing Baichy is not just choosing equipment, but embracing reliability and innovation. With 20 years of professional experience, we provide full lifecycle services to global mining partners, from solution design to after-sales support, helping your business continue to grow. Contact us to customize your exclusive crushing solution!

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.