30 kw Hammer Crusher | 10-25 t/h

As a mining crushing equipment manufacturer with 20 years of professional experience, we deeply understand our customers' core demands for equipment efficiency, energy consumption, and reliability. Among numerous crushing solutions, hammer crushers have always held an important position due to their simple structure, high crushing ratio, and high production efficiency.

This article will provide an in-depth analysis of a popular market model a 30 kW hammer crusher with a production capacity of 10-25 tons per hour, demonstrating how it becomes an excellent choice for small and medium-scale crushing operations.

The core parameters of this equipment are not accidental, but rather the optimal solution derived from engineering practice.

Power Matching (30 kW): The 30 kW motor power provides a powerful yet economical power source for the equipment. It is sufficient to drive the hammer heads to rotate at high speed, effectively crushing materials of medium hardness or less (such as limestone, gypsum, coal gangue, etc.), while finding the best balance between industrial electricity costs and initial investment, conforming to the modern equipment concept of "high efficiency and energy saving."

Processing Capacity Range (10-25 tons/hour): The wide processing capacity range of 10-25 tons/hour reflects the equipment's excellent adaptability and flexibility. The lower limit of production capacity guarantees basic productivity, while the upper limit leaves room for improvement by optimizing feeding and crushing conditions. This range accurately covers the needs of numerous application scenarios, such as small and medium-sized stone quarries, cement production line pre-processing, and construction waste recycling.

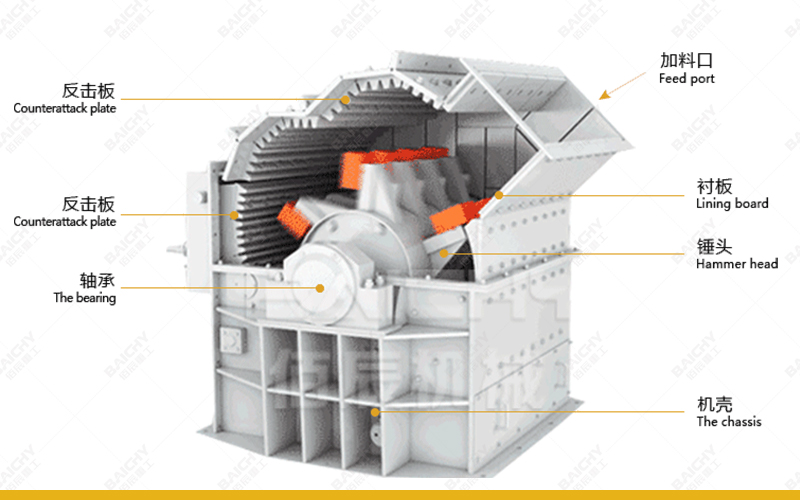

PC hammer crusher structure diagram

Equipment Overview: Core Structure and Working Principle

This hammer crusher mainly consists of a housing, rotor, hammer heads, grate bars, impact liner plates, and transmission device. During operation, the motor drives the rotor to rotate at high speed via a V-belt. When the material enters the crushing chamber, it is crushed by the impact of the high-speed rotating hammer heads. At the same time, the material is thrown against the impact liner plates inside the housing, resulting in secondary impact crushing. Qualified materials smaller than the grate bar gap are discharged, while larger materials continue to be impacted by the hammer heads in the chamber until they are crushed. This "impact" crushing principle gives it very high crushing efficiency.

Core Advantages: Why Choose Our Equipment?

Based on twenty years of manufacturing experience and technological expertise, the hammer crusher we offer boasts the following significant advantages:

1. High Efficiency and Energy Saving, Low Operating Costs: The 30 kW power configuration combined with an optimized chamber design ensures lower energy consumption per unit of output, saving significant electricity costs over long-term operation.

2. Robust Structure, Durable and Reliable: Key components (such as the rotor and main shaft) are forged or cast from high-quality alloy steel and undergo precision heat treatment and balance testing, resulting in strong resistance to impact loads, low equipment failure rate, and a long service life.

3. High Crushing Ratio, Uniform Output Particle Size: A single machine can achieve a crushing ratio of up to 10-25, directly crushing large materials to medium particle sizes or smaller in one pass, simplifying the process flow. The output particle size can be flexibly controlled by adjusting the grate bar gap, resulting in good product particle shape and low content of needle-shaped and flaky particles.

4. Easy Maintenance, Worry-Free Operation: The machine casing is designed with a hydraulic opening device or a maintenance side door, making it very convenient to replace worn parts (such as hammer heads and grate bars), significantly reducing downtime and improving equipment operating rate.

5. Wide Adaptability: It can not only process ordinary ores but also has good adaptability to materials with a certain degree of moisture, reducing clogging.

PC hammer crusher at the customer's site.

Application Cases: Witnessing Actual Performance

A Medium-Sized Limestone Quarry: The customer originally used a two-stage crushing system with a jaw crusher and a fine jaw crusher. They later switched to our 30 kW heavy-duty hammer crusher as a single-stage crushing solution. With an input particle size of ≤400mm and an output particle size adjusted to ≤25mm, a stable output of 22 tons/hour was achieved, electricity consumption was reduced by approximately 30%, the production line layout became more compact, and the return on investment period was significantly shortened.

Construction Waste Recycling Project: The materials processed mainly consisted of waste concrete blocks and bricks. The equipment demonstrated excellent resistance to impact from steel materials. By replacing with special grate bars, the processing capacity was controlled at around 15 tons/hour, producing aggregates that met recycling standards. The stable operation received high praise from the owner. Related Equipment Recommendations

To build a more efficient and complete crushing and screening production line, you may also need to consider the following equipment that complements our hammer crusher:

Feeding Equipment: ZSW series vibrating feeder, ensuring uniform and continuous feeding to maximize the crusher's capacity.

Screening Equipment: YK series circular vibrating screen, for classifying the crushed material, enabling closed-circuit circulation or finished product separation.

Conveying Equipment: TD series belt conveyor, used for material transfer between different stages of the process.

Primary Crushing Equipment: If the raw material size is very large (>600mm), a jaw crusher can be used for primary crushing to create a more efficient two-stage crushing process.

Frequently Asked Questions (FAQ)

Q1: What is the maximum size of material that this crusher can handle?

A1: It is generally recommended that the longest side of the feed material does not exceed 300-400mm, depending on the hardness of the material. For very hard materials, it is recommended to reduce the feed size to ensure equipment stability and hammer head lifespan.

Q2: What is the lifespan of the hammer heads? Is replacement complicated?

A2: The lifespan of the hammer heads is closely related to the abrasiveness of the material being crushed. When processing ordinary limestone, a set of hammer heads can last for hundreds of hours. Our equipment uses a symmetrical hammer head design; when one end is worn, it can be reversed for continued use. The replacement process is standardized, simple, and quick, using specialized tools and access doors.

Q3: How is the output particle size adjusted? What is the range?

A3: The output particle size is mainly adjusted by changing the gap between the bottom grate bars. The output particle size of this model can generally be adjusted within the range of 5-30mm. If the bottom grate bars are removed (for crushing wet materials or when extremely high output is required), the output particle size will increase, mainly controlled by the gap between the hammer heads and the impact liner.

Q4: Does the equipment require an additional dust removal device?

A4: A dust removal system is strongly recommended. Dust is generated during the crushing process. Depending on environmental regulations, a bag filter or water spray system can be connected to improve the working environment and meet environmental standards.

Q5: Do you provide installation guidance and after-sales service?

A5: Absolutely. As a manufacturer with 20 years of experience, we provide comprehensive technical support, including basic drawings, installation guidance, commissioning, and operation training. We guarantee a sufficient supply of spare parts and provide timely after-sales service to ensure your production line runs continuously and efficiently.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.