As a manufacturer with two decades of experience in the mining crushing industry, we deeply understand that for high-hardness, highly abrasive raw materials like granite, building an efficient, stable, and economical crushing production line is the cornerstone of a project's successful profitability.

Recently, many clients have inquired about solutions for a 300-ton/hour granite crushing line. This article, drawing on our years of project experience, will provide a comprehensive analysis of typical equipment configurations, technical specifications, and investment considerations for this capacity.

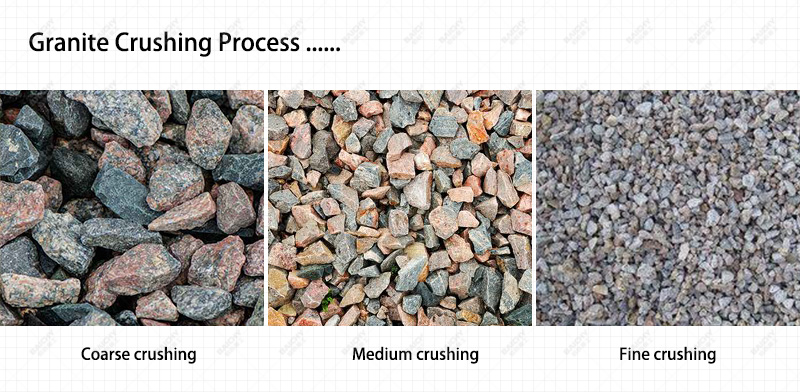

Granite Crushing

I. Granite Characteristics and Crushing Process Selection

Granite has a high Mohs hardness and high silica content, placing stringent requirements on the wear resistance and overall reliability of crushing equipment. A well-designed production line must adhere to the principle of multi-stage crushing and progressive energy reduction. For medium-to-large-scale production targets of 300 tons/hour, we typically recommend a classic three-stage closed-loop process to ensure excellent finished product particle shape and reasonable gradation, while controlling overall operating costs.

Mexican granite crushing production line customer site

II. Core Equipment Configuration Scheme for a 300-ton/hour Granite Crushing Production Line

The following is a stable and reliable benchmark configuration scheme that has been validated in multiple projects. Specific equipment selection may be slightly adjusted based on the maximum feed size of the raw material, final product requirements, and site conditions.

| Process Stage | Recommended Equipment Type | Model Example (For Reference Only) | Main Functions and Technical Requirements |

| Stage 1: Coarse Crushing | Jaw Crusher PE-750*1060 or equivalent | Responsible for crushing large raw stones (≤630mm) to medium particle size (approximately 150-200mm) | Requires a robust machine body and highly wear-resistant jaw plates. |

| Stage 2: Medium Crushing | Cone Crusher (single or multi-cylinder) HST300 or HPM400 | Core medium crushing equipment, further crushing the coarsely crushed stone. | For granite, a hydraulic cone crusher must be selected to obtain better particle shape through layered crushing and facilitate discharge port adjustment. |

| Section 3: Fine Crushing/Shaping | Cone Crusher (Multi-cylinder) or Impact Crusher | HPT300 or VSI1140 For high-grade sand and gravel, an impact crusher can be used for shaping; | If aggregate is the primary material and wear resistance is a concern, a multi-cylinder cone crusher can be used for fine crushing. |

| Screening and Closed-Circuit Circulation | Vibrating Screen | 3YK3070 or 2 units of 2YK2460 | Typically equipped with two or three layers of screens, separating the material into finished product, return material (for intermediate crushing), and material for fine crushing. |

| Feeding and Conveying | Vibrating Feeder | Belt Conveyor Series GZD1500×6000, B1000+ Ensures uniform and stable feeding. | All equipment is connected by belt conveyors; the belt width and speed need to be calculated and determined. |

Note: This configuration is the basic process framework. The actual production line must also be equipped with a complete electrical control system, dust removal and noise reduction system, steel structure foundation, and maintenance and hoisting equipment. These are indispensable parts to ensure continuous and stable operation.

Mexican granite crushing production line customer site

III. Investment Overview: More Than Just a Single Machine Price

One of the most pressing questions for customers is, How much does this equipment cost? We must be honest and inform you that the price of a complete 300-ton/hour granite crushing production line is the comprehensive value of the system, not simply the sum of inpidual machines. The total price mainly covers the following aspects:

| Major Cost Categories | Content Description | Estimated Percentage (For Reference Only) |

| Main Equipment Costs | Main equipment costs such as crushers, screening machines, and feeders listed in the table above. | Approximately 50%-60% of total investment |

| Auxiliary System Costs | Belt conveyors (length has a significant impact), electrical control system, dust removal system, steel structure platform. | Approximately 20%-30% of total investment |

| Installation and Commissioning | Equipment foundation construction, installation guidance, on-site commissioning, personnel training, etc. | Approximately 5%-10% of total investment |

| Transportation and Taxes | Equipment logistics costs and related taxes. | Approximately 5%-10% of total investment |

Important Note: Market prices vary significantly due to factors such as brand, configuration, and steel price fluctuations. A typical domestic mainstream brand production line capable of crushing 300 tons/hour granite typically requires an investment of several million RMB in main equipment. We strongly recommend that customers provide specific site conditions and product requirements to obtain a precise configuration plan and detailed quotation.

IV. Added Value from 20 Years of Experience

Choosing a manufacturer with long-term experience means you gain much more than just steel equipment:

• Optimized Process Design: Avoiding overkill or capacity bottlenecks, saving you investment and operating costs from the source.

• Guaranteed Equipment Reliability: Based on the characteristics of granite, we have accumulated exclusive experience in the selection and processing of materials for key components such as the grinding mill wall and crushing wall, significantly extending the life of wear-resistant parts.

• Full Lifecycle Service: From site planning, foundation drawings, and installation guidance to operation and maintenance support, we provide comprehensive support to ensure your production line reaches full capacity quickly and generates continuous profits.

Investing in a 300-ton/hour granite crushing line is a significant decision. While focusing on equipment specifications and pricing, it's crucial to comprehensively evaluate the supplier's technical expertise, project experience, and long-term service capabilities. With twenty years of professional experience, we are committed to becoming your reliable partner, jointly building efficient and robust rock-breaking tools to lay a solid production foundation for your mining business.

Please feel free to contact us anytime for personalized solutions and accurate quotes.