When choosing the best granite crusher, you need to consider multiple factors, including the type, specifications, processing capacity, wear resistance, maintenance cost, and usage scenarios of the crusher. The following is an evaluation and recommendation of several common granite crushers based on reference articles and related digital information:

Cone crusher - granite crushing machine

Features:

Good wear resistance, multiple models, including spring type, single-cylinder hydraulic, multi-cylinder hydraulic, inertial cone crusher, etc.

Large crushing ratio, high efficiency, low energy consumption, less dust, uniform product particle size, stable operation, low failure rate, and not easy to over-crush.

Applicable scenarios: Suitable for the fine crushing stage in hard rock crushing, but not suitable for crushing wet and sticky ores.

Recommended reasons: Cone crushers perform well in hard rock crushing, especially in situations where high crushing ratio and particle size uniformity are required.

Jaw crusher - granite crushing machine

Features:

Simple structure, reliable operation, and easy maintenance.

High crushing rate, can quickly crush larger granite stones to smaller sizes.

Applicable scenarios: Commonly used for primary crushing of granite.

Recommended reason: As a primary crushing equipment, the jaw crusher is widely used in the field of granite crushing due to its high crushing rate and reliability.

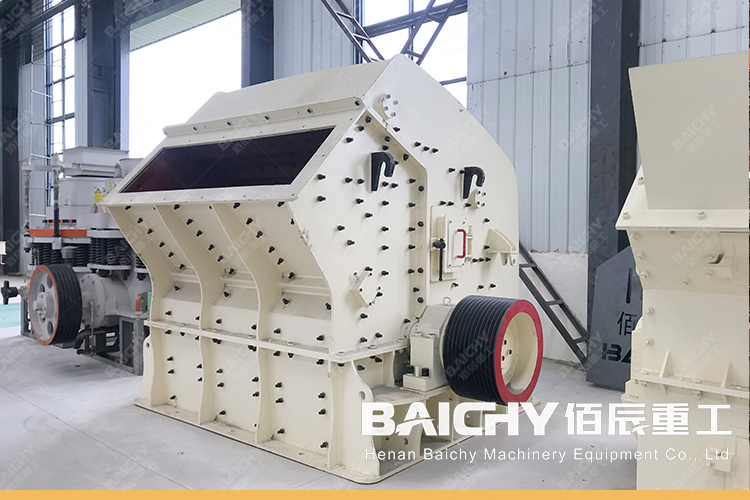

Impact crusher - granite crushing machine

Features:

The crushed particles have a good shape and are suitable for granite stones with medium hardness.

It has a shaping function, the product is cubic and has a high bulk density.

Applicable scenarios: occasions with high requirements for the particle size of the finished product.

Recommended reason: While providing good crushing effect, the impact crusher can also ensure the integrity of the particle shape, which is suitable for scenarios with high requirements for particle size.

Roller crusher (including granite roller sand making machine) - granite crushing machine

Features:

Simple structure, easy operation and low maintenance cost.

The discharge particle size can be adjusted according to demand, which is suitable for granite crushing needs of different particle sizes.

Applicable scenarios: occasions with specific requirements for the discharge particle size.

Recommended reason: The roller crusher has a flexible and adjustable discharge particle size, which can meet the personalized needs of different users.

Choosing the best granite crusher requires comprehensive consideration based on specific usage scenarios and needs. Cone crushers excel in crushing hard rocks, jaw crushers are suitable for primary crushing, impact crushers are suitable for scenarios with high requirements for particle size, and roll crushers have flexible and adjustable discharge particle sizes. When choosing, you also need to consider factors such as the equipment's wear resistance, maintenance costs, and the manufacturer's after-sales service.