In mining, building materials, chemical, and metallurgical industries, ball mills are crucial equipment for regrinding crushed materials. When choosing a ball mill, a primary and core question is: should you use a dry ball mill or a wet ball mill?

These two processes are not simply substitutes, but rather solutions tailored to different needs and application scenarios. An incorrect choice can lead to low efficiency, substandard products, or even equipment damage. This article will delve into the intricacies of dry and wet ball milling, providing you with a clear selection guide.

I. Core Difference: The Presence of Water

As the names suggest, the fundamental difference lies in whether a liquid (usually water) is used as the grinding medium during the grinding process.

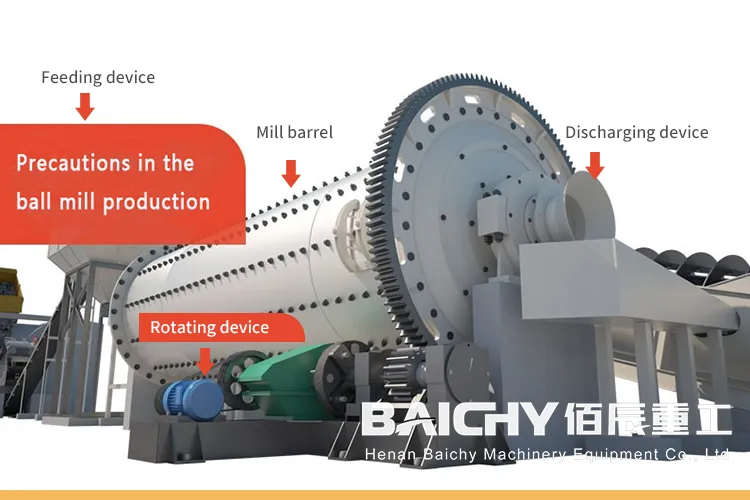

• Dry Ball Mill: Within a sealed grinding cylinder, dry materials are entirely ground and impacted by grinding media such as steel balls. No water is added during the grinding process, and the finished product is powder.

• Wet Ball Mill: Within the grinding cylinder, materials and water are mixed in a specific ratio to form a slurry. The grinding media impact and grind the materials within the slurry, resulting in a slurry-like finished product.

II. Advantages and Disadvantages Comparison

After understanding their core differences, let's look at their respective advantages and disadvantages.

Features of Dry Ball Mills:

• Advantages:

◦ No drying required: The finished product is dry powder, which can be used or sold directly, eliminating the need for subsequent dehydration and drying processes, resulting in lower equipment investment and energy consumption.

◦ No water pollution: Suitable for materials that are sensitive to water or in areas with scarce water resources, making it more environmentally friendly.

◦ Less equipment corrosion: The waterless environment reduces equipment corrosion, resulting in relatively lower maintenance costs.

• Disadvantages:

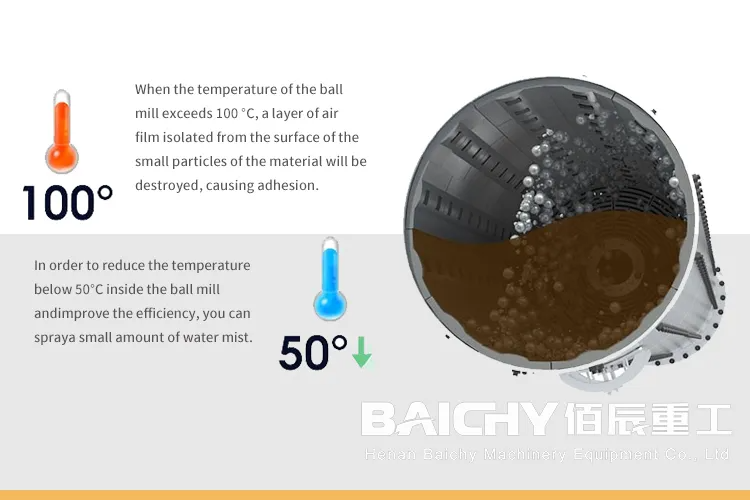

◦ Prone to dust generation: Requires high sealing performance; otherwise, it can cause environmental pollution and material loss.

◦ Lower grinding efficiency: During dry grinding, materials easily adhere to the mill and steel balls, leading to higher energy consumption and the possibility of over-grinding.

◦ Narrow application range: Not suitable for grinding highly viscous materials or materials requiring subsequent wet processing.

Features of Wet Ball Mills:

• Advantages:

◦ High grinding efficiency: The "overflow" effect of water can promptly carry away fine powder, preventing over-grinding and adhesion. Under the same conditions, the output is usually higher than that of dry mills.

◦ No dust pollution: Clean working environment, better meeting environmental protection requirements.

◦ Uniform particle size of finished product: Good slurry flowability helps to obtain products with a more concentrated particle size distribution.

• Disadvantages:

◦ Requires dehydration and drying: The finished product is a slurry. If dry powder is required, additional equipment such as filtration and drying must be added, increasing investment and operating costs.

◦ Equipment wear and corrosion: The water environment will accelerate the corrosion of the mill and steel balls, resulting in higher maintenance costs.

◦ Water consumption: Not suitable for water-scarce areas, and wastewater treatment is required.

III. How to Choose? Consider These Three Key Factors

The choice between dry and wet mills ultimately depends on your specific needs. Please refer to the following decision-making process:

1. Material Properties are the Primary Basis

• Choose Dry Milling: Your material is water-sensitive (e.g., cement, silica fume, graphite, certain non-metallic minerals), or subsequent processes require dry powder.

• Choose Wet Milling: Your material does not undergo physical or chemical changes upon contact with water, and subsequent processes involve wet beneficiation (e.g., flotation, magnetic separation) or it is itself a slurry product.

2. Finished Product Requirements Determine the Process Path

• Dry Powder Required: If the customer or downstream processes explicitly require dry powder, and the material allows for dry grinding, prioritize dry ball mills to avoid high drying costs.

• Slurry or Wet Processing Required: If the finished product is a slurry (e.g., ceramic glaze), or requires wet purification, wet ball mills are the only option, as they integrate grinding and classification, resulting in a simpler process.

3. Consider Cost and Environmental Factors

• Environmental Factors: In areas with scarce water resources or extremely high dust control requirements, careful consideration is necessary. Dry grinding requires dust collection, while wet grinding requires wastewater treatment.

• Investment and Operating Costs: Evaluate the cost of the entire production process. While wet grinding may have higher single-machine efficiency, the cost of dehydration and drying in the final stage, if dry powder is required, may far exceed the cost of dry grinding itself.

IV. Summary

| Characteristics | Dry Ball Mill | Wet Ball Mill |

| Core Media | Air | Water |

| Finished Product | Dry Powder | Slurry |

| Grinding Efficiency | Relatively Low | High |

| Environmental Pollution | Dust | wastewater |

| Equipment Corrosion | Light | Heavy |

| Applicable Scenarios | Water-sensitive materials, requiring dry powder, water-scarce areas | Wet mineral processing, requiring slurry, pursuing high efficiency |

Final Recommendation: There is no absolute "better," only "more suitable." Before making a decision, it is strongly recommended to conduct material trials to evaluate the effectiveness, energy consumption, and cost of the two processes in your specific situation using actual data, thereby making the most scientific and economical choice.

If you are unsure about the properties of the material, please feel free to contact our technical team. We will provide you with professional selection advice and solutions.