In the increasingly competitive sand and gravel aggregate market, granite, as a representative of high-hardness and highly abrasive rock, has always been crucial for the profitability of a crushing plant and even the entire mining project due to its efficient processing.

For investors and operators seeking excellence, building an efficient granite crushing production line is not simply a matter of piling up equipment, but a systematic project involving the selection of core equipment, process layout, and cost control. This article will delve into how to select the true "heart" of your granite crushing plant—the granite crusher—and how to maximize overall efficiency around it.

I. Characteristics of Granite and Crushing Challenges

Granite has a high Mohs hardness (typically 6-7), a dense structure, and a high silicon content, which means:

• High energy consumption: Crushing requires a huge energy input.

• High wear: Extremely abrasive to the crusher's wear parts (such as jaw plates, hammers, and side guards).

• High cost: The frequency of equipment maintenance and the cost of replacing wear parts directly impact operating profits.

Therefore, the primary principle for selecting a granite crusher is: "heavy impact, light grinding," achieving layered crushing to reduce wear; or "hard against hard," employing centrifugal impact crushing to ensure the finished product's particle shape.

II. Core Equipment Showdown: Selection Strategies for Granite Crusher at Different Stages

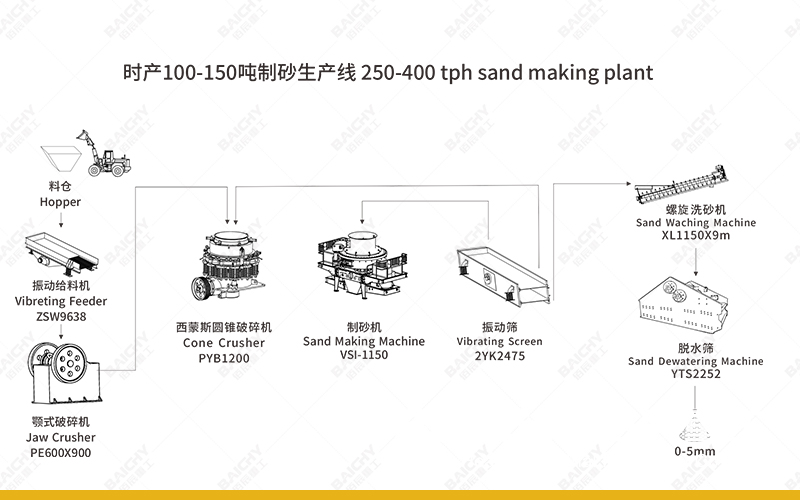

An efficient production line is typically an organic combination of multiple crushing stages. For granite, common core equipment configurations are as follows:

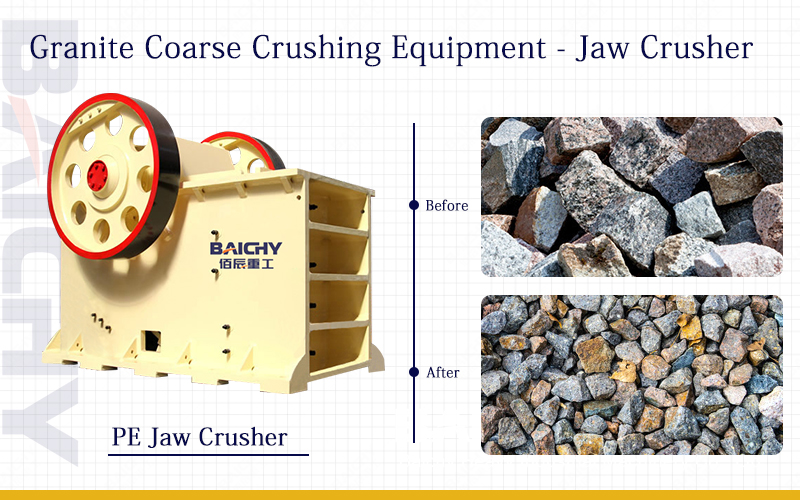

1. Coarse Crushing Stage (Jaw Crusher - The Undisputed Pioneer)

◦ Role: Responsible for receiving huge rough stones (up to thousands of millimeters) from the mine, performing the first crushing, reducing the raw material to below 250mm.

◦ Selection Points: A heavy-duty jaw crusher with a large feed opening and deep crushing chamber must be selected. Employing more impact- and wear-resistant manganese steel jaw plates and an integrated cast steel frame ensures stability and an ultra-long service life under enormous impact forces. At this stage, equipment reliability and low failure rate are far more important than a slight increase in efficiency.

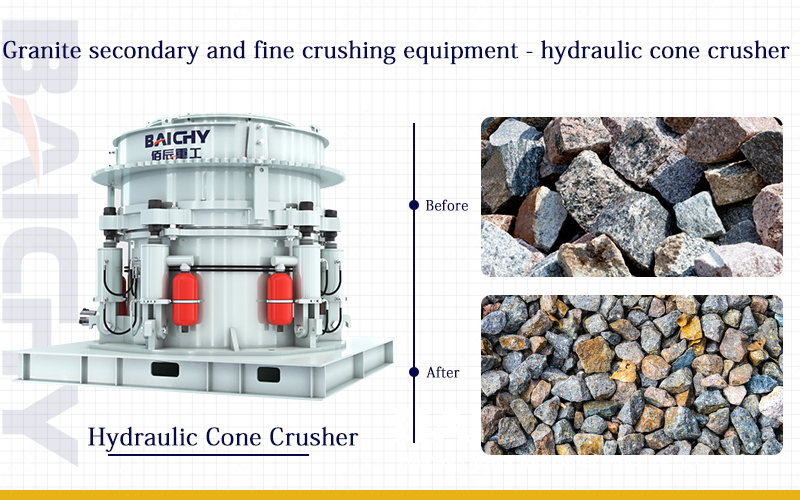

2. Secondary Crushing Stage (Cone Crusher - The Essential Choice)

◦ Role: Receives the material after primary crushing and performs secondary crushing. The output particle size is typically 40-60mm.

◦ Selection Considerations: Cone crushers are the absolute mainstay for processing granite. They employ the principle of interlayer crushing, achieving crushing through the mutual compression and grinding of particles. The wear-resistant parts consumption is far lower than that of impact crushers. Modern hydraulic cone crushers with hydraulically adjustable discharge ports, overload release protection, and automatic cavity clearing functions should be prioritized. This not only allows for precise control of product particle size but also significantly reduces downtime and protects core equipment components.

3. Fine Crushing and Shaping Stage (Vertical Shaft Impact Crusher - The Finishing Touch)

◦ Role: Further crushes and optimizes the particle shape of the material after secondary crushing, producing high-quality manufactured sand and cubic finished aggregates.

• Selection Considerations: Although the "stone-on-iron" crushing mode results in higher wear, vertical shaft impact crushers that can switch between "stone-on-stone" and "stone-on-iron" modes are crucial for producing high-quality sand and gravel. For granite, models using ultra-wear-resistant materials (such as high-chromium cast iron and tungsten carbide) for wear parts like the side guards and alloy cutter heads are essential. Their greatest value lies in significantly increasing the value of the finished product, meeting the stringent requirements for aggregate particle shape in high-grade construction, highways, and bridges.

III. Systematic Thinking for High-Efficiency Crushing Production Lines

An excellent crusher is a point; an optimized production line is a surface. True efficiency is reflected in the synergistic effect of the system:

• Pre-screening: Separating soil and fine particles before coarse crushing reduces the burden on the coarse crushing equipment.

• Closed-loop circulation: Screening the crushed material; unqualified material is returned to the crusher for further crushing, ensuring that the final product particle size fully meets the standards.

• Automated Control: Through sensors and a PLC system, real-time monitoring of equipment operating parameters (such as spindle load, oil temperature, and oil pressure) enables automatic adjustment and fault early warning, achieving "unmanned" or minimally staffed operation and ensuring continuous and stable production.

Choosing a granite crusher for a high-efficiency granite crushing plant is a strategic decision that balances output, finished product specifications, investment, and long-term operating costs. There is no "single best" equipment, only the solution "most suitable for your project needs." As your reliable mining equipment partner, we not only provide a full range of high-performance, high-wear-resistant crushing equipment from coarse crushing to sand making, but also leverage our extensive project experience to provide you with full lifecycle services from site surveys and process design to equipment installation, commissioning, and operational training. Let us use our professional solutions to help you conquer the hardest granite and gain core competitiveness in the market.