In the long journey of gold ore beneficiation, crushing is truly the first hurdle, and the foundation for determining the overall economic benefits and technical indicators of the beneficiation process. Its task is simple yet crucial: to process the massive amounts of raw ore through a series of coarse to fine crushing and screening processes, preparing it into particle sizes suitable for subsequent grinding and beneficiation (such as flotation and cyanidation). Today, we will delve into the core of gold ore crushing—the perfect combination of equipment and technology.

I. Why is gold ore crushing so special?

Before discussing specific equipment, we need to understand the characteristics of gold ore. Gold is usually impregnated in ore (such as quartz) in the form of fine or micrograined particles, commonly known as encased gold. The purpose of crushing is not only to reduce particle size, but also to achieve the liberation of gold—that is, to release the gold particles from the gangue that encapsulates them, creating the prerequisite for subsequent recovery. Therefore, the efficiency of the crushing process and the particle size of the final product directly affect the gold recovery rate.

II. Core Crushing Equipment Family Photo

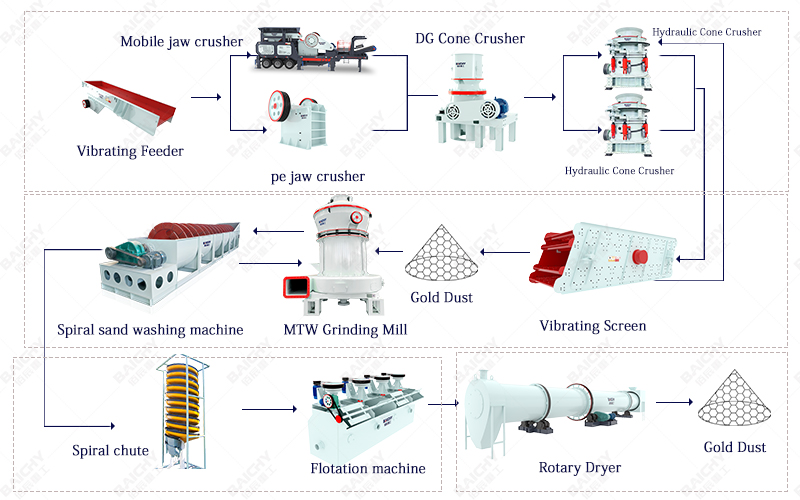

A high-efficiency gold ore crushing production line typically consists of the following key equipment, each with its own specific function and interconnected.

1. Jaw Crusher: The Iron Stomach of the Coarse Crushing Stage

• Role: The primary crushing stage of the production line, responsible for processing the largest pieces of raw ore (diameter up to 1 meter or more).

• Working Principle: Simulates the movement of an animal's jaws, crushing the ore through the compression between the moving and fixed jaws.

• Advantages: Simple structure, robust and durable, large processing capacity, and low feed requirements. It is the most reliable and economical choice for coarse crushing.

2. Cone Crusher: The Main Force of Medium and Fine Crushing

• Role: Receives the coarse material from the jaw crusher and performs secondary (medium) and tertiary (fine) crushing.

• Working Principle: Achieves continuous crushing of the ore through the rotational compression between the moving and fixed cones.

• Advantages: High crushing efficiency, low energy consumption, and uniform product particle size. Especially suitable for processing hard, highly abrasive gold ores. Modern hydraulic cone crushers can also automatically clear the chamber and adjust the discharge opening, exhibiting a high degree of automation.

3. Impact Crusher (Sand Making Machine): A Versatile Fine Crusher

• Role: Can serve as an alternative for medium and fine crushing, particularly suitable for ores of medium hardness and low abrasiveness.

• Working Principle: Employs the principle of stone-on-stone or stone-on-iron, using a high-speed rotating impeller to propel the ore, causing it to collide with each other or with the lining plates inside the crushing chamber.

• Advantages: Good product particle shape (cubic), large crushing ratio, but relatively high wear-resistant parts consumption.

4. Auxiliary Equipment: An Indispensable Supporting Role

• Feeder: Such as a vibrating feeder, providing uniform and continuous feeding to the jaw crusher to ensure stable production.

• Vibrating Screen: The commander in the crushing process, responsible for classifying the crushed material according to particle size. Qualified particles are sent to the next process or powder silo, while unqualified coarse particles are returned to the crusher for further crushing (forming a closed-loop cycle). This is key to improving efficiency and controlling product quality.

III. Detailed Explanation of Classic Gold Ore Crushing Process

Based on processing capacity, ore properties, and investment scale, there are two main typical processes:

1. Two-Stage Closed-Loop Crushing Process

• Process: Raw ore → Vibrating feeder → Jaw crusher (coarse crushing) → Cone crusher/impact crusher (fine crushing) → Vibrating screen → (Coarse material over the screen is returned to the cone crusher, qualified material under the screen is fed into the mill)

• Features: This is currently the most mainstream and classic process. It has moderate investment, a simple process, and is easy to control product particle size, well meeting the requirements of most gold mine beneficiation plants. The closed loop formed by the vibrating screen ensures the fineness of the final product.

2. Three-Stage Closed-Circuit Crushing Process

• Process: Raw ore → Vibrating feeder → Jaw crusher (coarse crushing) → Cone crusher (medium crushing) → Vibrating screen (pre-screening) → Fine crushing cone crusher (fine crushing) → Vibrating screen (inspection screening) → Qualified material enters the mill.

• Features: Suitable for large-scale concentrators or applications with very hard ores. By adding a primary crushing stage, the particle size of the material entering the final grinding stage can be significantly reduced (typically to below 10-15mm), thereby drastically reducing energy consumption in the grinding stage (grinding energy consumption accounts for more than 50% of the total plant energy consumption), achieving the energy-saving goal of more crushing, less grinding. Although the initial investment is higher, the long-term operating costs are lower.

Process Selection Comparison Table

| Process Type | Applicable Scenarios | Advantages | Disadvantages |

| Two-stage closed-circuit | Small to medium scale, medium ore hardness | Low investment, simple process, convenient operation and maintenance | Relatively coarse product particle size, affects mill efficiency |

| Three-stage closed-circuit | Large scale, hard ore | Fine product particle size, significant energy saving effect, more crushing, less grinding | High investment, complex process, large footprint |

IV. Core Considerations for Equipment and Process Selection

When selecting suitable equipment and processes, detailed mineralogical research and scheme demonstration of the ore process must be carried out, focusing on the following points:

1. Ore physical properties: hardness, moisture content, mud content, abrasiveness, etc. Cone crushers are preferred for hard ores, rather than impact crushers.

2. Maximum particle size and throughput of raw ore: Determines the model of coarse crushing equipment.

3. Target crushed product particle size: Related to the number of crushing stages required and the selection of fine crushing equipment.

4. Investment budget and operating costs: Balance initial investment with long-term energy consumption and wear parts consumption costs.

5. Site Layout: The process flow should be as compact as possible to minimize hoisting equipment and conveying distances.

Gold ore crushing is not simply a matter of breaking large pieces into smaller ones, but a meticulously designed systems engineering project. Selecting suitable crushing equipment and optimizing the crushing process are the cornerstones for improving the technical indicators and economic benefits of gold ore beneficiation. An efficient and stable crushing system can provide qualified, fully liberated raw materials for subsequent grinding and beneficiation operations, thus laying a solid foundation for ultimately obtaining glittering gold.