Detailed explanation of the working principle of dewatering vibrating screen | Structural features, workflow and application scenarios

Dewatering vibrating screen is an efficient solid-liquid separation equipment, widely used in mining, environmental protection, chemical industry and other fields. This article will introduce its structural composition, working principle, workflow in detail, and analyze its application advantages in different industries to help users better select and maintain.

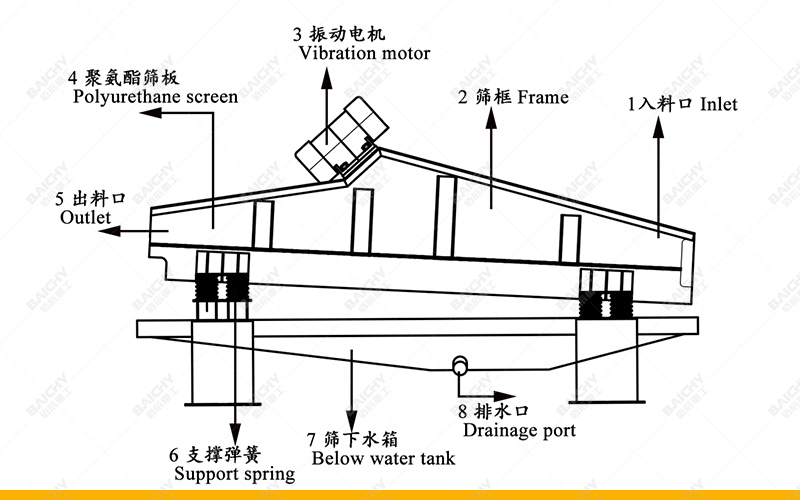

1. Structural composition of the dewatering vibrating screen

The dewatering vibrating screen is mainly composed of the following core components:

• Screen box: Made of stainless steel or polyurethane, it is corrosion-resistant and wear-resistant and is used to carry materials.

• Vibration motor: Provides high-frequency vibration power to quickly dehydrate the material on the screen surface.

• Shock-absorbing spring: Reduces vibration transmission during equipment operation and improves stability.

• Screen: Select different apertures (such as 0.1mm~5mm) according to the characteristics of the material to affect the dehydration efficiency.

• Feed port and discharge port: used for material input and dry material and liquid discharge after dehydration respectively

2. Working principle of dewatering vibrating screen

The dewatering vibrating screen achieves solid-liquid separation through high-frequency vibration + gravity separation. The specific process is as follows:

✔ Vibration motor drive

• The vibration motor generates high-frequency vibration (usually 1000~3000 times/minute), driving the screen box to make elliptical or linear motion.

• The vibration amplitude (amplitude) can be adjusted to meet the dehydration needs of different materials.

✔ Material dehydration process

• Feeding stage: The wet material enters the screen surface evenly from the feed port.

✔ Vibration screening:

• Under the action of vibration, fine particles and water pass through the screen into the lower layer (liquid collection tank).

• Larger particles (dry materials after dehydration) move forward along the screen surface and are finally discharged from the discharge port.

✔ Solid-liquid separation:

• Liquid: flows into the bottom drain through the screen to achieve recovery or discharge. • Solids: The moisture content of the dry material after dehydration can be reduced to 10%~20% (depending on the material).

3. Application scenarios of dehydration vibrating screens

Dehydration vibrating screens play an important role in many industries, and typical applications include:

• Mining: Used for tailings dehydration, fine sand recovery in sand washing plants, and reducing transportation costs.

• Environmental protection: Treat sludge and sediment from sewage treatment plants to improve solid waste treatment efficiency.

• Chemical industry: Separate crystal particles from mother liquor to improve product purity.

• Food industry: Dehydration and drying of materials such as starch and beans.

4. Selection and maintenance of dehydration vibrating screens

① Selection points

• Processing capacity: Select a suitable model based on the processing capacity per hour (such as 5~50 tons).

• Screen material: Corrosion-resistant (stainless steel) or wear-resistant (polyurethane) to adapt to different materials.

• Vibration mode: linear (suitable for coarse particles) or elliptical (fine screening).

② Maintenance recommendations

• Check the screen regularly to prevent blockage or damage that affects the dehydration effect.

• Lubricate the vibration motor bearings to extend the life of the equipment.

• Adjust the amplitude to adapt to different material characteristics to avoid excessive vibration and damage to the equipment.

The dehydration vibrating screen achieves efficient solid-liquid separation through high-frequency vibration + screening technology, which is of great value in the mining, environmental protection, and other industries. Correct selection and maintenance can greatly improve dehydration efficiency and reduce operating costs. If you need to know more about equipment parameters or customized solutions, please consult professional manufacturers!