In many industrial sectors such as mining, building materials, and metallurgy, we often need to crush and grind solid materials into extremely fine powder. In this process, one piece of equipment plays an indispensable role: the ball mill.

What is a ball mill?

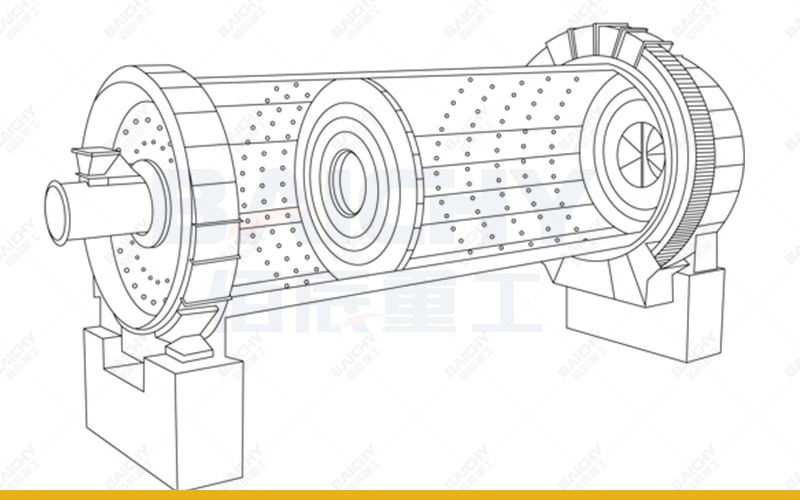

A ball mill is a highly efficient industrial pulverizing device. Its core structure consists of a horizontally placed cylinder that can rotate around a central axis. The cylinder contains a certain amount of grinding media, typically steel balls, ceramic balls, or other wear-resistant materials.

Its working principle is very simple yet highly effective: when the ball mill cylinder begins to rotate under the drive of a motor, the grinding media inside the cylinder are carried to a certain height by centrifugal force and friction, and then fall or cascade down due to gravity. During this process, the falling balls exert a strong impact and grinding effect on the material inside the cylinder, gradually pulverizing the lumpy or granular material into fine powder through continuous impact and friction.

What are the main uses of a ball mill?

Ball mills have a wide range of applications, covering almost all industries that require grinding materials into fine powder:

1. Mineral Processing Industry (Core Application): Used to grind mined ore, fully separating useful minerals from gangue (waste rock) to prepare for subsequent mineral processing (such as flotation and magnetic separation). This is the largest application area for ball mills.

2. Cement and Building Materials Industry: Used to grind cement raw materials, clinker, and produce slag powder, etc., and is one of the core pieces of equipment in cement production.

3. Chemical Industry: Used to grind various chemical raw materials, ensuring the fineness and uniformity of the materials and promoting chemical reactions.

4. Power Industry: Used in thermal power plants to grind coal into pulverized coal to improve combustion efficiency.

5. New Materials and Ceramics Industry: Used for the preparation of ultrafine powders, such as the mixing and grinding of electronic ceramic materials, magnetic materials, coatings, and pigments.

What are the key advantages of ball mills?

Ball mills have remained a mainstream grinding equipment for over a century thanks to a series of significant advantages:

• High grinding efficiency and fine output: Through the dual action of impact and grinding, they can produce products with uniform particle size distribution and very fine particle size.

• Strong adaptability and wide application: They can be used for both dry and wet grinding; they can handle materials of various hardnesses, from soft materials to extremely hard ores.

• Large production capacity and continuous operation: A complete range of equipment specifications is available, from small experimental machines to large industrial mills, meeting the production needs of different scales and enabling 24-hour continuous operation.

• Relatively simple structure and reliable operation: The main structure is not complex, making the equipment easy to maintain and ensuring stable and reliable operation.

• Easy to seal and can be ground with inert gas protection: For flammable and explosive materials, inert gases such as nitrogen can be filled into the cylinder for protection, ensuring safe production.

In summary, ball mills, with their reliable structure, excellent grinding effect, and wide adaptability, have become an indispensable key piece of equipment in modern industry. Whether in large-scale mining and beneficiation plants or in sophisticated new materials laboratories, they silently play a vital role as "grinding experts."