In the field of industrial powder processing, the Raymond mill is a renowned name. Since its inception, it has become an indispensable key piece of equipment in the fine powder preparation process due to its stable performance, efficient grinding capabilities, and wide applicability. However, many people are unclear about the specific application scenarios for this "meritorious" piece of equipment. Today, we will comprehensively analyze the applications of the Raymond mill.

I. Core Principle: How Does a Raymond Mill Work?

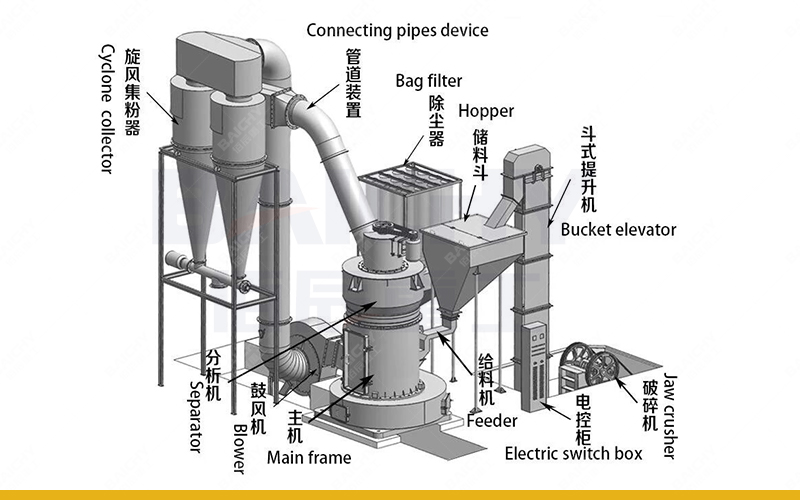

Before understanding the application scenarios, let's summarize its principle in one sentence: The Raymond mill uses the centrifugal rolling of grinding rollers within a grinding ring to crush and pulverize materials. Then, an analyzer classifies the materials, collecting powders that meet the required fineness, while coarse powders are returned for regrinding. This closed-loop process makes it particularly suitable for processing various non-metallic minerals with a Mohs hardness of 7 or less and a moisture content of 6% or less.

II. Detailed Explanation of Main Application Scenarios

The application of the Raymond mill permeates almost every aspect of basic industry. The following are its main application areas:

1. Mining Industry: The "Main Force" in Non-Metallic Mineral Processing

This is the most traditional and core application area of the Raymond mill. It excels at processing hundreds of non-metallic minerals, especially suitable for:

• Calcium carbonates: such as calcite, marble, chalk, and limestone. The processed fine powder is an important filler in the plastics, coatings, and toothpaste industries.

• Silicates: such as quartz, feldspar, bentonite, and kaolin. Products are widely used in ceramics, glass, refractory materials, and oil drilling.

• Sulfates: such as barite and gypsum. Barite powder is a weighting agent in oil drilling mud; gypsum powder is a core raw material for building gypsum board.

2. Metallurgical and Chemical Industries: Material Pretreatment and Waste Recycling

In metallurgical and chemical plants, Raymond mills play a crucial role in material pretreatment and resource recovery.

• Raw material preparation: Grinding phosphate rock, manganese ore, etc., into powder to facilitate subsequent sintering or chemical reactions.

• Waste Recycling: High-efficiency grinding of industrial waste such as blast furnace slag and fly ash produces high-quality slag powder and fly ash, which can be used as active admixtures in cement and concrete, turning waste into treasure.

3. Building Materials Industry: The "Cornerstone" of Green and Environmentally Friendly Building Materials

The building materials industry is a huge consumer market for Raymond mill products.

• Cement Production: Used to prepare cement raw materials and clinker; its grinding efficiency directly affects cement quality and energy consumption.

• New Wall Materials: Producing decorative building materials such as plaster and putty powder; the fine powder processed by Raymond mills has advantages such as uniform particle size and good flowability.

4. Other Emerging and Specialized Fields

With technological development, the applications of Raymond mills are constantly expanding, for example:

• Power Plant Desulfurization: Grinding limestone into fine powder as an absorbent for flue gas desulfurization.

• Agriculture: Producing pesticide carriers, feed additives, etc.

III. Summary of the Advantages of Choosing a Raymond Mill

Why do these industries favor Raymond mills? • Wide Application: Multi-functional and highly adaptable.

• High Efficiency: High screening rate and relatively low energy consumption.

• Environmentally Friendly and Reliable: Employs a pulse dust collector, resulting in low dust emissions and low noise.

• High Degree of Automation: Enables assembly line operation from feeding to finished product packaging.

In summary, the Raymond mill, with its superior versatility and stability, has successfully served a wide range of fields, from traditional mining to modern green building materials. If you are looking for solutions to the challenges of grinding non-metallic minerals, metallurgical slag, chemical raw materials, etc., the Raymond mill is undoubtedly a reliable choice that has stood the test of time.

Contact us now for a customized material grinding solution!