What are the main functions of a semi-autogenous grinding mill? Analysis of working principles and application advantages

Semi-autogenous grinding mill (SAG Mill) is a key equipment in the mining and mineral processing industries, and is widely used in the crushing and grinding process of ores. Compared with traditional ball mills, semi-autogenous grinding mills combine the advantages of autogenous grinding and ball milling, greatly improving production efficiency and reducing energy consumption. This article will deeply analyze the main functions, working principles and important role of semi-autogenous grinding mills in the mineral processing process.

1. Main functions of semi-autogenous grinding mills

Semi-autogenous grinding mills have the following core functions in the ore processing process:

1.1 Integration of coarse and fine crushing

Using the ore itself as a grinding medium, it reduces dependence on steel balls and reduces energy consumption.

It can handle large pieces of ore (200-300mm), and complete coarse and fine crushing at the same time, simplifying the process flow.

1.2 Efficient grinding to improve the recovery rate of mineral processing

Through the impact and friction between steel balls and ore, the mineral particles can reach the ideal dissociation particle size, improving the subsequent flotation or leaching efficiency.

Applicable to the processing of various metal ores such as gold, copper, and iron.

1.3 Energy saving and consumption reduction, reducing operating costs

Compared with the traditional crushing + ball milling process, the semi-autogenous mill can reduce energy consumption by 30%-40% and reduce production costs.

Advanced drive systems (such as variable frequency motors) are used to further optimize energy consumption.

1.4 Strong adaptability and can handle complex ores

Applicable to ores with high hardness and high mud content to reduce the risk of blockage.

The grinding effect can be optimized by adjusting parameters such as steel ball ratio and speed.

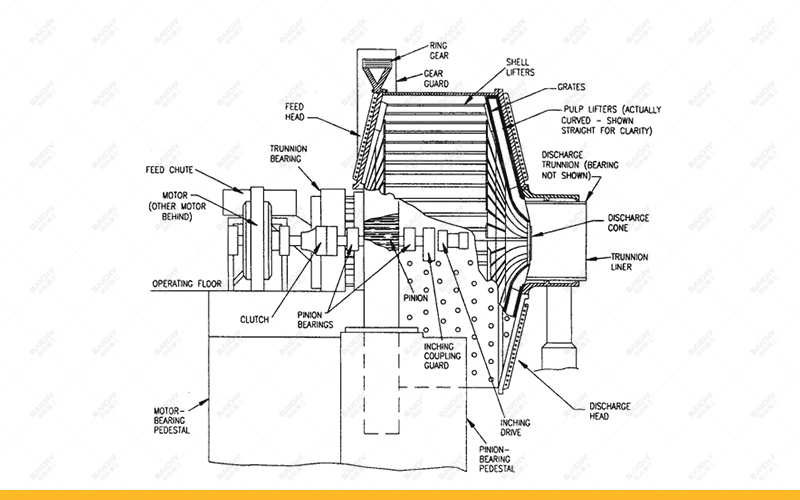

2. Working principle of semi-autogenous mill

The operation of semi-autogenous mill is based on the following key mechanisms:

• Ore self-grinding: large pieces of ore collide and rub against each other in the cylinder to achieve initial crushing.

• Steel ball assisted grinding: A small amount of steel balls (usually accounting for 8%-15% of the cylinder volume) enhance the impact force and improve the efficiency of fine crushing.

• Grading discharge: The slurry with qualified particle size is discharged through the sieve plate at the discharge end, and the coarse particles continue to be circulated and ground.

3. Semi-autogenous mill vs. traditional ball mill: core advantage comparison

| Comparison items | Semi-autogenous mill | Traditional ball mill |

| Crushing method | Autogenous grinding + steel ball | assisted Pure steel ball grinding |

| Feed particle size | 200-300mm | <25mm |

| Energy consumption | Low (energy saving 30%+) | High |

| Process flow | Simplified (reducing the crushing stage) | Matching crusher is required |

| Applicable ore | High hardness, muddy ore | Medium hardness ore |

4. Typical application scenarios of semi-autogenous mill

• Gold ore dressing plant: Improve the dissociation degree of gold particles and improve the recovery rate.

• Copper ore processing: Processing complex ores such as porphyry copper ore to reduce the grade of tailings.

• Iron ore dressing: Replace traditional three-stage crushing and reduce equipment investment.

• Spodumene grinding: Ensure that the fineness meets the flotation requirements.

5. How to optimize the efficiency of the semi-autogenous mill?

• Adjust the steel ball ratio: Dynamically adjust the size and proportion of steel balls according to the hardness of the ore.

• Control the feed particle size: Avoid excessively large pieces of ore that lead to reduced efficiency.

• Regularly maintain the liner: Reduce wear and maintain stable grinding effect.

• Use intelligent control system: Real-time monitoring of load, power and other parameters, and automatically optimize the operating status.

With its advantages of efficient crushing, energy saving and consumption reduction, and simplified process, the semi-autogenous mill has become the core equipment of modern ore dressing plants. Whether it is processing high-hardness ores or improving metal recovery rates, semi-autogenous mills can significantly improve production efficiency. If you need to know more about equipment selection or technical parameters, please consult professional mining equipment suppliers!

Keywords: Semi-autogenous mill, SAG Mill, ore crushing, grinding equipment, ore dressing process, energy saving and consumption reduction