In modern cement, metallurgy, and non-metallic mineral processing industries, the efficiency and energy consumption of the raw material grinding process directly determine the cost and benefits of the entire production line. The SRM1300 vertical roller mill (vertical mill), as core equipment in large-scale grinding processes, is becoming the preferred equipment for many enterprises to achieve large-scale, refined production due to its superior performance and significant energy-saving advantages.

I. Why is the SRM1300 vertical roller mill your best choice?

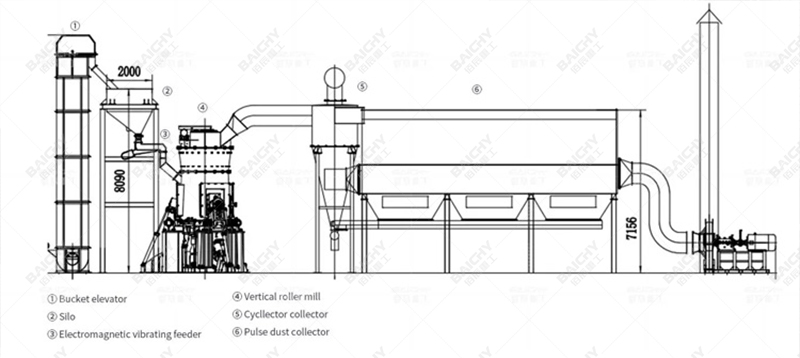

The SRM1300 vertical mill is more than just a grinding mill; it's a highly efficient grinding system integrating crushing, grinding, drying, powder selection, and conveying. Compared to traditional ball mills, it brings revolutionary changes:

• Extremely low power consumption and significant benefits: Utilizing the bed grinding principle, energy consumption is reduced by 30%-50% compared to traditional ball mills, significantly lowering production costs.

• High grinding efficiency and huge capacity: Designed for large-volume processing, a single unit can meet the raw material supply needs of a large-scale production line, doubling production efficiency.

• Stable and easily adjustable product fineness: The built-in high-efficiency dynamic classifier allows for flexible and precise adjustment of product fineness within the range of 80-600 mesh, with concentrated particle size distribution and stable quality.

• Simplified process flow and smaller footprint: Integrating multiple functions into one compact system layout, it effectively saves on civil engineering investment and factory space.

• Excellent environmental performance: The system is completely sealed, operates with low noise, and can be equipped with a pulse dust collector to achieve ultra-low dust emissions, meeting environmental protection requirements.

II. Core Application Areas of the SRM1300 Vertical Roller Mill

The SRM1300 vertical roller mill is a highly versatile piece of equipment, widely used for the fine grinding of the following materials:

• Cement Industry: Grinding cement raw materials, clinker, slag, fly ash, etc., it is a core piece of equipment in modern cement production lines.

• Metallurgical Industry: Ultrafine grinding of blast furnace slag and water slag to produce high-performance slag powder.

• Non-metallic mineral processing: Suitable for deep processing of non-metallic minerals such as calcite, limestone, barite, bentonite, and gypsum, increasing product added value.

• Power industry: Used for limestone powder preparation in power plant desulfurization agents.

III. Key Technical Features of the SRM1300 Vertical Roller Mill

1. Robust grinding roller and grinding disc assembly: Made of high-quality alloy materials, highly wear-resistant, long service life, and low maintenance costs.

2. Advanced hydraulic system: Provides stable grinding pressure, smooth operation, and enables no-load start-up with roller lifting, reducing starting current.

3. High-efficiency dynamic classifier: High sorting efficiency, precise control of finished product fineness, ensuring product quality meets standards.

4. Reliable reducer system: Core transmission components operate smoothly, with high transmission efficiency, ensuring long-term continuous operation of the equipment.

5. Intelligent control system: Enables remote monitoring, automatic feeding, and fault diagnosis, making operation simpler and management easier.

IV. Choose Us for Comprehensive Solutions Beyond Equipment

We are not just a manufacturer of SRM1300 vertical roller mills, but also your trusted process partner. We offer:

• Professional Selection Guidance: Recommending the most suitable equipment model and configuration based on your material characteristics and capacity requirements.

• Comprehensive Technical Support: Providing one-stop service from site planning and basic design to installation, commissioning, and personnel training.

• Reliable After-Sales Service: Ample spare parts supply and a rapid technical response team ensure the continuous and stable operation of your production line.

In an increasingly competitive market, choosing efficient and energy-saving grinding equipment is key to reducing operating costs and enhancing product competitiveness. The SRM1300 vertical roller mill, with its mature technology, reliable performance, and excellent economic efficiency, has become the first choice for industry upgrades.

If you are looking for efficient, energy-saving large-scale raw material grinding equipment, or would like to learn more about SRM1300 vertical roller mill pricing and specifications, please contact our professional engineers immediately! We will provide you with customized solutions.