In the mining and steel industries, efficient and reliable material handling is central to profitability and sustainable development. Whether it's hard iron ore or abrasive industrial byproduct steel slag, transforming it into high-value-added aggregates or recycled resources through a well-designed crushing production line is a challenge faced by many companies.

Stone Crushing Plant PDF, Download ↓↓↓

I. Iron Ore Crushing Production Line

Iron ore, the grain of the steel industry, requires crushing as the first and crucial step in the entire ore beneficiation process. Our iron ore crushing production line is specifically designed for handling high-hardness, highly abrasive ores.

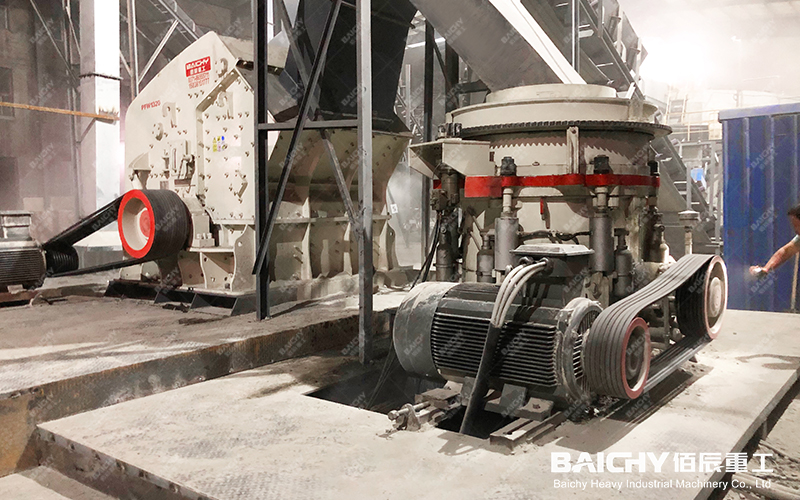

• Core Process: Typically employs a classic two-stage, one-screening or three-stage, one-screening process. Jaw crushers are used for primary crushing, utilizing their powerful crushing force to handle large pieces of raw ore; cone crushers are used for secondary crushing, efficiently completing medium and fine crushing tasks and effectively controlling product particle size.

• Technical Highlights: The production line is equipped with advanced iron removal devices and vibrating feeders to protect downstream equipment. Multi-layer vibrating screens achieve strict particle size classification, ensuring uniform particle size of materials entering the grinding process, significantly improving ball mill efficiency, and thus reducing overall energy consumption.

II. Steel Slag Crushing Production Line

Steel slag is a major solid waste product from the steel smelting process, but it contains recyclable metallic iron and hard particles that can be used as building materials. Crushing steel slag is not only environmentally friendly but also creates considerable economic benefits.

• Core Process: The core of steel slag treatment lies in crushing-screening-magnetic separation-iron removal. First, primary crushing is performed using a jaw crusher, followed by fine crushing using specialized crushers (such as hydraulic cone crushers or impact crushers). The most crucial step is the recovery of the abundant metallic iron through multi-stage magnetic separation, achieving resource recycling.

• Technical Highlights: The production line features a high-strength anti-wear design and efficient iron removal capabilities. The produced steel slag aggregate can be widely used in road construction, brick making, cement production, and other fields, truly realizing turning waste into treasure, in line with the circular economy concept.

Why Choose Our Crushing Production Line Solution? We offer a full range of services, from solution design and equipment selection to manufacturing, installation, and commissioning. Our production lines are renowned for their high reliability, low operating costs, and intelligent control, aiming to maximize return on investment for our clients and jointly drive the green transformation of industrial production.