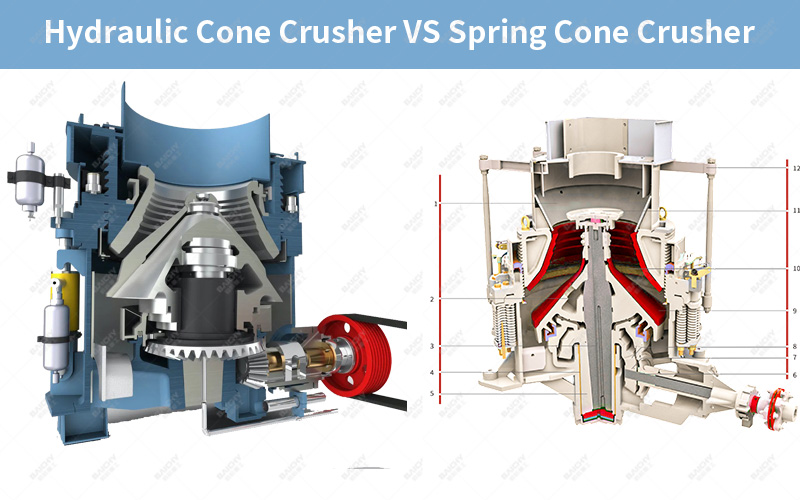

1. Working Principle Comparison

Hydraulic Cone Crusher:

▪ Use the hydraulic system to adjust the discharge port and overload protection.

▪ Hydraulic cylinder provides crushing force, and the pressure is adjustable.

▪ High degree of automation, one-button operation is possible.

Spring Cone Crusher:

▪ Relies on the spring system to provide crushing force and overload protection.

▪ AThe mechanical structure is relatively simple.

▪ The discharge port needs to be adjusted manually.

2. Comparison of performance characteristics

| Features | Hydraulic cone crusher | Spring cone crusher |

| Automation degree | High | Low |

| Adjustment convenience | Hydraulic adjustment, convenient and fast | Mechanical adjustment, more complicated |

| Overload protection | Hydraulic system automatic release | Spring compression release |

| Maintenance cost | High | Low |

| Initial investment | High | Low |

| Product particle size | More uniform | Relatively uniform |

| Applicable materials | Medium and high hardness materials | Medium and low hardness materials |

3. Comparison of advantages of hydraulic cone crusher VS spring cone crusher

• Advantages of hydraulic cone crusher

High degree of automation: The hydraulic system is used to adjust the discharge port and overload protection, which can realize one-button operation and reduce manual intervention.

Convenient and quick adjustment: The hydraulic cylinder adjusts the size of the discharge port without stopping the machine, which improves production efficiency.

Overload protection is more reliable: When encountering unbreakable objects, the hydraulic system automatically releases pressure to protect the equipment from damage.

More uniform product size: The hydraulic system provides stable crushing force, making the finished product size more uniform, suitable for high-quality aggregate production.

Applicable to high-hardness materials: The hydraulic system provides higher crushing force, suitable for crushing high-hardness ores such as granite and basalt.

Easy maintenance: The hydraulic system can remotely monitor faults, and some models support automatic cavity cleaning to reduce downtime.

• Advantages of spring cone crusher

Simple structure and low maintenance cost: The mechanical structure is relatively simple, easy to repair, and the cost of replacing accessories is low.

Low initial investment: The price is usually cheaper than the hydraulic cone crusher, suitable for users with limited budgets.

Stable operation: The spring system provides stable crushing force, suitable for medium and low hardness materials (such as limestone and dolomite).

Low energy consumption: Compared with hydraulic cone crushers, spring cone crushers usually have lower energy consumption and are suitable for long-term stable operation.

Strong adaptability: Strong adaptability to material moisture content and viscosity, not easy to clog.

Mature technology: Long development history, rich operation and maintenance experience, suitable for traditional mining enterprises.

Conclusion

Hydraulic cone crushers have advantages in automation, adjustment convenience and handling of high-hardness materials, and are suitable for modern large-scale production lines; while spring cone crushers are simple in structure, easy to maintain and economical, and are suitable for small and medium-sized production needs. The final choice should be based on a comprehensive consideration of specific production requirements, budget constraints and long-term operation planning.

Hydraulic cone crusher vs spring cone crusher: FAQ

1. What is the core difference between a hydraulic cone crusher and a spring cone crusher?

• Hydraulic cone crusher: It uses a hydraulic system to adjust the discharge port and overload protection, with a high degree of automation, suitable for hard materials and fine crushing.

• Spring cone crusher: It relies on mechanical springs to provide crushing force and overload protection, with a simple structure and low maintenance cost, suitable for medium and low hardness materials.

2. Which cone crusher is more suitable for crushing hard ores such as granite and basalt?

The hydraulic cone crusher is more suitable because:

• The hydraulic system can provide a higher crushing force

• Automatic overload protection can reduce the risk of equipment damage

• The product particle size is more uniform, suitable for high-quality aggregate production

3. Can the spring cone crusher be used to crush hard materials?

Yes, but it is not recommended for long-term use because:

• The crushing force of the spring system is limited and the efficiency is low

• Frequent overloading will accelerate the wear of the spring and liner, increasing maintenance costs

• The uniformity of the finished product particle size is not as good as that of the hydraulic cone crusher

4. Is the maintenance cost of the hydraulic cone crusher really high?

• The initial maintenance cost is high (the hydraulic system requires professional maintenance)

• But in the long run, the efficiency is higher, the downtime is reduced, and the overall benefits may be better

• Some new hydraulic cone crushers adopt a modular design to reduce the difficulty of maintenance

5. Is the energy consumption of the spring cone crusher really lower than that of the hydraulic cone crusher?

• The hydraulic system requires additional power to drive the hydraulic pump

• The spring cone crusher has a simple mechanical structure and less energy loss

• But the unit energy consumption (tons/kWh) of the hydraulic cone crusher may be better because of its higher crushing efficiency