In industries such as mining, building materials, and metallurgy, primary crushing is the first critical step in the production line. Choosing a high-efficiency and stable jaw crusher is crucial.

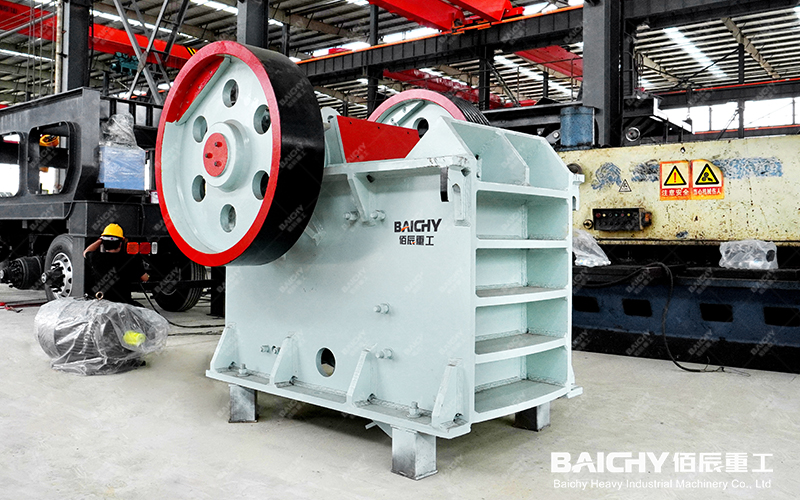

The PE 500x750 model, with its superior performance and wide applicability, has become a star product for medium and fine crushing operations. This article will take you deeper into understanding this high-quality equipment and teach you how to identify a truly reputable manufacturer.

I. Why is the PE 500x750 jaw crusher so popular?

PE 500x750 is not just a simple string of numbers; it precisely defines the core parameters of the equipment: the feed opening size is 500mm x 750mm. This specification allows it to efficiently process various ores, rocks, and other materials with a particle size not exceeding 425mm. Its outstanding performance is reflected in:

• Excellent processing capacity: Hourly output can reach 50-100 tons, with high production efficiency, meeting the needs of most small and medium-sized production lines.

• High crushing ratio and uniform output: Optimized cavity design ensures a high crushing ratio, while adjusting the discharge port yields a final product with uniform particle size, reducing the burden on the next crushing stage.

• Robust structure and stable operation: Utilizing high-strength steel and welding technology, the moving jaw assembly is durable. The eccentric shaft uses large forgings, ensuring stable operation under heavy loads.

• Easy maintenance and low operating costs: A reasonable structural design allows for easy replacement of core wear-resistant parts (such as jaw plates), effectively reducing downtime and long-term maintenance costs.

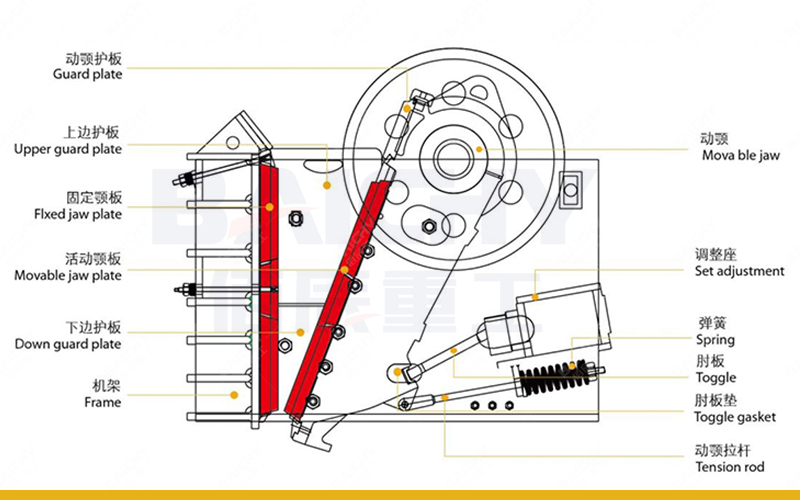

II. Structure of PE 500x750

A high-quality jaw crusher's value extends far beyond its specifications. The real difference lies in the details and craftsmanship:

• Moving jaw assembly: Is it made of high-quality cast steel? Has the welding process undergone non-destructive testing? This directly affects the equipment's service life.

• Bearing brand and lubrication: Does it use internationally renowned brands such as SKF and FAG bearings? Does a comprehensive centralized lubrication system ensure adequate lubrication of critical components?

• Flywheel Design: Is the flywheel's inertia precisely calculated to balance the load and reduce energy consumption and fluctuations?

• Safety Protection Devices: Is it equipped with an overload release protection device that automatically resets upon encountering an unbreakable object to prevent equipment damage?

III. How to Choose a Reliable PE 500x750 Manufacturer?

Choosing a manufacturer is more important than choosing the equipment itself. A responsible manufacturer can provide long-term value assurance.

1. Technical Strength and R&D Capabilities: Assess whether the manufacturer has a professional technical team and continuous R&D investment, and whether it can provide customized solutions based on your specific working conditions.

2. Production Process and Quality Control: Understand the manufacturer's production equipment, process flow, and quality management system (such as ISO9001 certification). Ideally, conduct an on-site visit or watch a production video.

3. Case Studies and Reputation: Request the manufacturer to provide successful case studies of similar projects and customer feedback; this is the most direct proof of its strength.

4. After-sales Service Commitment: Reliable manufacturers provide comprehensive after-sales service, including installation guidance, technical training, timely spare parts supply, and global technical support.

Investing in a high-quality PE 500x750 jaw crusher is the cornerstone of building an efficient and profitable production line. It is not just a simple production tool, but also a reliable business partner. We hope this article helps you fully understand this equipment and make an informed decision in choosing a reputable manufacturer.