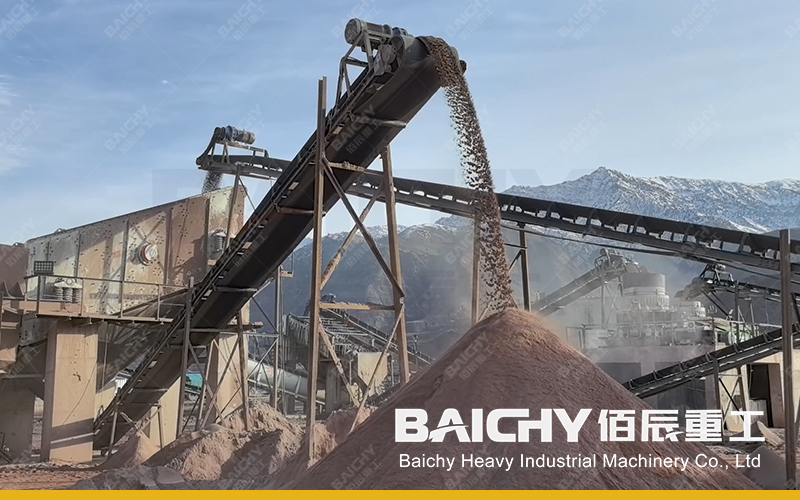

When considering investing in crushing and screening equipment, many owners face a crucial decision: choose a mobile, flexible production line or invest in a robust, efficient, large-scale stationary plant? While mobile equipment is highly regarded for its flexibility, stationary crushing and screening equipment remains the unshakable cornerstone of the industry when handling large-scale, high-intensity production tasks. It represents the gold standard in terms of capacity, stability, and long-term investment returns.

I. Why Choose Stationary Equipment?

Stationary equipment is not outdated technology, but rather a specialized solution for specific needs. Its significant advantages include:

• Exceptional processing capacity: Designed for high-intensity, 24/7 continuous operation, its single-line capacity far exceeds that of mobile equipment, meeting the massive aggregate demands of large infrastructure projects.

• Unparalleled stability and durability: Robust foundation installation ensures extremely smooth operation, less equipment wear, longer lifespan, and guarantees continuous and reliable production.

• Superior Finished Material Quality and Controllability: Complex multi-stage crushing and screening processes (such as a combination of jaw crusher + cone crusher + sand making machine) can be easily implemented, thereby precisely controlling the output particle shape and gradation to produce high-value-added, high-quality aggregates.

• Lower Long-Term Operating Costs: Although the initial investment may be higher, its higher energy efficiency, easier-to-maintain design, and longer service life make the cost per ton of finished product highly competitive.

• High Degree of Automation and Intelligence: Easy integration with advanced central control systems enables fully automated operation, real-time monitoring, and data analysis, significantly reducing reliance on manual labor and improving operational efficiency and safety.

II. How Should Your Production Line Be Layout?

A high-efficiency stationary crushing and screening production line typically includes:

1. Primary Crushing Section: Jaw crushers act as the main force, processing large pieces of raw stone.

2. Secondary and Fine Crushing Section: Cone crushers or impact crushers perform secondary and tertiary crushing.

3. Screening Section: Multi-layer vibrating screens precisely classify materials according to different specifications.

4. Sand Making and Shaping Section (Optional): Impact crushers are used to produce high-quality manufactured sand.

It is perfectly suited for:

• Large-scale quarries and mines with an annual output of over one million tons.

• Major engineering projects with strict requirements for the particle shape and gradation of finished aggregates (such as hydropower dams and highways).

• Working conditions with high-hardness and highly abrasive raw materials.

III. Investing in Stationary Equipment:

Focus on Long-Term Return on Investment (ROI) Choosing stationary equipment is a strategic long-term investment. When evaluating, one should not only look at the initial price, but also consider the following:

• Capacity Output: Can it meet market demand for the next 5-10 years?

• Operating and Maintenance Costs: What are the power consumption, wear part lifespan, and labor costs?

• Finished Product Value: Can it produce a variety of high-value aggregate specifications to enhance product competitiveness?

• Equipment Lifespan: Can the production line operate stably for 15 or even 20 years or more? In today's pursuit of maximum efficiency and profitability, stationary crushing and screening equipment continues to play an irreplaceable role in large-scale aggregate production due to its powerful production capacity, superior stability, and lower cost per ton. For investors seeking long-term, stable, and high-return operations, it is undoubtedly the most solid and reliable choice.

If you are planning a large quarry or seeking to upgrade existing capacity, please contact our team of experts. We will tailor the optimal stationary crushing and screening solution for you based on your raw material characteristics and production objectives.