In numerous fields such as mining, road construction, and construction waste treatment, on-site crushing of stone is a crucial step. However, traditional stationary crushing production lines are limited by power supply and site constraints, often proving ineffective in remote mountainous areas or under conditions of no or unstable power. In these situations, diesel-powered jaw crushers become an irreplaceable solution.

I. Why Choose Portable Diesel-Powered Crushing Equipment?

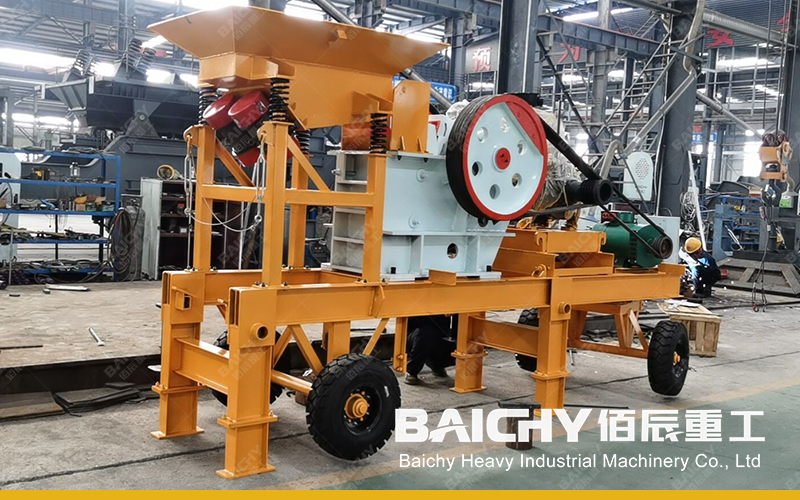

1. Ultimate Mobility and Flexibility: The equipment integrates feeding, crushing, and conveying, equipped with heavy-duty tires or tracks, allowing for rapid transport to the work site, achieving crushing on the go, significantly reducing material transportation costs.

2. Strong Environmental Adaptability: It does not rely on an external power grid, providing ample power solely from a diesel engine, perfectly overcoming harsh working conditions such as no power, power shortages, and unstable voltage, making it the preferred choice for field operations.

3. Powerful Hard Rock Crushing Capability: The core crushing component utilizes mature PE jaw crusher technology, featuring an optimized deep cavity design and high-strength jaw plates. Specifically designed for crushing high-hardness rocks such as granite, basalt, and river pebbles, it boasts high crushing efficiency and uniform output particle size.

4. Rapid Production and Reduced Costs: Eliminating the time and costs associated with laying cables and constructing fixed foundations, the equipment can be put into production immediately upon arrival, significantly shortening the project cycle and improving return on investment.

II. The Perfect Demonstration of PE Series Jaw Crusher Technology on Diesel Power

Our portable stone crushing equipment is powered by the proven PE series jaw crusher. Its features include:

• V-shaped cavity design: Increases the depth of the crushing chamber, improves processing capacity, and ensures greater output.

• High-manganese steel jaw plates: Excellent wear resistance and impact resistance, extending equipment lifespan and reducing maintenance costs.

• Heavy-duty eccentric shaft: Precision-machined and heat-treated, ensuring smooth operation and high load-bearing capacity, guaranteeing the reliability of the equipment when crushing hard rock.

The powerful combination of a diesel engine and a PE jaw crusher creates a true mobile crushing fortress.

III. Application Scenarios

• Remote Mountain Mining: Directly deployed to mining sites for on-site primary crushing of raw ore.

• Highway and Railway Construction: Mobile crushing of rocks along construction routes, providing a continuous supply of base aggregate for the project.

• Construction Waste Recycling: Mobile processing of construction waste at urban demolition sites, turning waste into valuable resources.

Choosing a suitable diesel jaw crusher is crucial for ensuring project progress under harsh working conditions. It combines the high efficiency of a hard rock PE jaw crusher with the convenience of portable stone crushing equipment, making it a powerful tool for modern, intelligent construction. If you are facing the challenge of mobile crushing without electricity, please feel free to contact us for customized equipment solutions and quotes.