In modern mineral processing, solid-liquid separation is a crucial step. It directly affects product quality, water recycling, and environmental protection. Mining dewatering screens are one of the core pieces of equipment for achieving efficient solid-liquid separation.

I. What is a Mining Dewatering Screen?

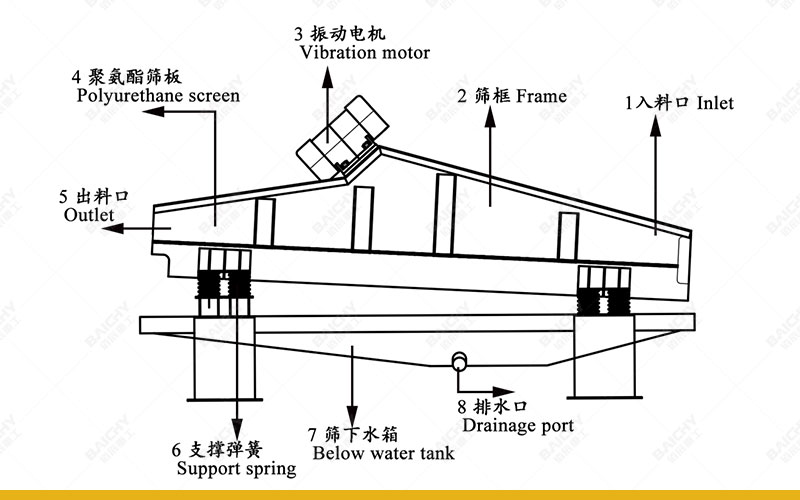

As the name suggests, a mining dewatering screen is a screening machine specifically designed for industries such as mining, metallurgy, and coal, used for dewatering, desliming, and demediuming fine-grained materials. It uses the excitation force generated by a high-frequency vibrating motor to throw the material on the screen surface and move it forward. During this process, water is separated through the screen holes, while dry (or with acceptable moisture content) solid particles are discharged from the end of the screen.

II. Core Advantages of Mining Dewatering Screens

• High-efficiency dewatering: Utilizing high-frequency vibration, it achieves high dewatering efficiency, effectively reducing the moisture content of materials, facilitating transportation and storage.

• Energy saving and environmental protection: It enables the recycling of sand washing wastewater and tailings water, reducing fresh water consumption and wastewater discharge, meeting environmental protection requirements.

• Enhance Product Value: Effective dewatering of concentrates improves product grade and increases economic benefits.

• Robust and Durable Structure: Designed specifically for harsh mining environments, it utilizes wear-resistant steel and rubber springs, resulting in a long equipment lifespan and low maintenance costs.

• Smooth Operation: The vibrating motor provides a stable excitation source, resulting in low noise and minimal impact on the foundation.

III. Main Application Scenarios of Mining Dewatering Screens

• Tailings Dewatering in Mineral Processing Plants: Dry discharge of tailings after magnetic separation and flotation, enabling safe management and resource utilization of tailings ponds.

• Coal Slime Recovery in the Coal Industry: Recovering fine coal particles from coal washing wastewater, turning waste into treasure and improving coal recovery rates.

• Dewatering of Manufactured Sand in Aggregate Plants: Ensuring that the manufactured sand leaving the plant meets the moisture content standards for construction sand.

• Dewatering and Desliming of Non-metallic Minerals such as Quartz Sand and Potassium Feldspar.

IV. How to Choose a Suitable Mining Dewatering Screen?

Choosing the right dewatering screen requires considering several factors:

1. Material characteristics: Particle size distribution, density, viscosity, initial moisture content, etc.

2. Processing capacity requirements: The amount of material to be processed per hour (tons/hour).

3. Dewatering target: The desired final moisture content.

4. Equipment type: Common types include linear vibrating dewatering screens and high-frequency vibrating dewatering screens; choose according to process requirements.

5. Brand and after-sales service: Choose a manufacturer with mature technology and reliable after-sales service.

A high-efficiency, reliable mining dewatering screen is a powerful tool for mining enterprises to achieve energy conservation, emission reduction, quality improvement, increased revenue, and green production. Correct selection and maintenance will bring you significant economic and environmental benefits.