In the field of sand and gravel aggregate production, crushing is the "leading force" of the entire process line, and its efficiency and stability directly determine the return on investment of the entire project.

Among numerous coarse crushing equipment, the PE750x1060 jaw crusher, with its durable structure, stable and efficient output, and wide material adaptability, has become the undisputed "core" of medium and large-sized stone quarries.

I. Core Advantages: Why Choose PE750x1060?

The PE750x1060 is not just a simple model; it represents a mature and reliable coarse crushing solution. Its core advantages are mainly reflected in:

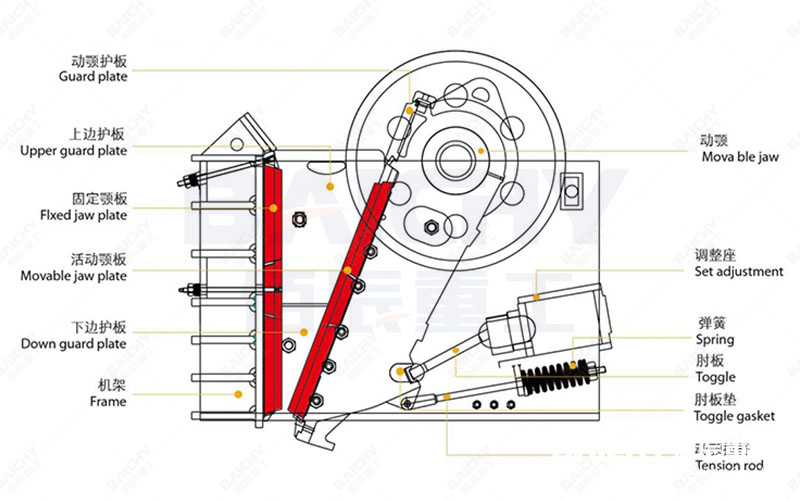

1. Robust and Durable Structure: The moving jaw, side guard plates, and other core components are manufactured using high-quality, high-strength manganese steel. The overall frame design is robust, capable of withstanding enormous crushing forces and impact loads, resulting in a long equipment lifespan.

2. Powerful crushing force and large feed opening: The 750x1060mm feed opening size allows it to easily handle large stones up to 630mm in size, such as granite, basalt, and river pebbles, resulting in immense crushing force and a high crushing ratio.

3. Flexible discharge adjustment: By adjusting the wedge block device below the jaw plate, the discharge opening size can be easily controlled, obtaining primary aggregates of various sizes from 80-180mm to meet the feeding requirements of downstream secondary crushing.

4. Stable operation and easy maintenance: The simple structure and intuitive working principle make daily maintenance and replacement of wear parts (such as jaw plates) convenient, effectively reducing long-term operating costs and downtime.

II. Technical Parameters Overview:

Data Reflecting Core Strength When understanding a piece of equipment, data is the most intuitive language. The following are the key technical parameters of the PE750x1060 jaw crusher:

• Feed opening size: 750x1060 mm

• Maximum feed size: ≤630 mm

• Discharge opening adjustment range: 80-180 mm

• Processing capacity: 110-320 t/h (varies depending on discharge opening size and material hardness)

• Spindle speed: 250 r/min

• Main motor power: 90-110 kW

• Equipment weight: Approximately 28 tons (slightly varies depending on the manufacturer)

As can be seen from the parameters, this model is very suitable for medium to large-sized sand and gravel aggregate production lines with a capacity of 200-300 tons per hour, serving as the core equipment for primary crushing.

III. Working Principle: A Simple and Reliable "Stone-Eating Beast"

The PE750x1060 jaw crusher operates on the classic "curved compression" principle. The electric motor drives the pulley via a V-belt, causing the eccentric shaft to rotate. The movable jaw, connected to the eccentric shaft, performs a periodic reciprocating motion: when the movable jaw approaches the fixed jaw plate, the material between the two jaw plates is crushed by compression and splitting; when the movable jaw moves away from the fixed jaw plate, the crushed material is discharged from the discharge port under gravity. This cycle repeats continuously, achieving efficient crushing operations.

IV. Application Scenarios: Where Does It Shine?

The PE750x1060 is an ideal choice for processing medium to high hardness materials, widely used in:

• Mining: Primary crushing of metallic and non-metallic ores.

• Aggregate plants: Used for crushing granite, basalt, river pebbles, limestone, etc., to produce coarse aggregate for construction.

• Infrastructure construction: Providing a stable supply of raw materials for large-scale projects such as highways, railways, and hydropower.

• Construction waste recycling: Preliminary crushing of large pieces of concrete, bricks, etc.

V. Investment Analysis and Purchase Recommendations

The most frequently asked question by customers during consultations is, "How much does a PE750x1060 jaw crusher cost?" In reality, the price of the equipment is influenced by many factors, including brand, configuration, steel market conditions, and after-sales service, so there is no fixed answer. Typically, the investment for one unit ranges from hundreds of thousands to millions of RMB.

When purchasing, we recommend focusing on the following points rather than simply comparing prices:

1. Manufacturer Strength: Choose a brand with a good reputation and years of technological accumulation to ensure equipment quality and after-sales service.

2. Core Component Materials: Pay close attention to whether vulnerable parts such as jaw plates and side guard plates are made of wear-resistant materials such as high-manganese steel, as this directly affects the equipment's lifespan.

3. Overall Configuration: Details such as the motor brand and bearing model also determine the equipment's stability and energy consumption level.

4. On-site Inspection: If possible, visiting the manufacturing plant or an existing customer's site is the best way to understand the actual condition of the equipment.

The PE750x1060 jaw crusher has established a classic position in the aggregate crushing industry due to its superior reliability, powerful crushing capacity, and wide adaptability. If you are planning a medium-to-high output sand and gravel production line and seeking a stable and efficient starting tool, the PE750x1060 is undoubtedly a core choice worthy of serious consideration.

Contact us for a customized PE750x1060 jaw crusher solution and detailed quotation!