In the complex process of gold ore beneficiation, crushing and grinding are crucial steps determining the final recovery rate. Among these, the ball mill, as the core equipment in the grinding operation, directly affects the degree of liberation of gold minerals and subsequent leaching effects.

Baichy Heavy Industry delves into a highly regarded piece of equipment in small and medium-sized gold mines—the 900x1800 gold ore ball mill—to see how it becomes a powerful tool for improving return on investment.

I. Why is a dedicated ball mill needed for gold ore grinding?

Gold ore is typically embedded in the ore in a fine or micro-fine particle form. To achieve ideal liberation of inpidual particles, the ore needs to be ground sufficiently and precisely.

Insufficient grinding prevents the gold minerals from being exposed, affecting the recovery rate; excessive grinding leads to mud formation, adsorption of reagents, and increased consumption, which is also detrimental to recovery.

The 900x1800 ball mill is specifically designed for the characteristics of gold ore, with optimizations in rotational speed, liners, and grinding media ratios to achieve efficient and controllable grinding results.

II. Core Advantages of the 900x1800 Gold Mine Ball Mill

1. Precise Specifications: "900x1800" refers to a cylinder diameter of 900 mm and a length of 1800 mm. This specification is ideal for small to medium-sized gold mine beneficiation plants or pilot lines, ensuring processing capacity without equipment idleness or energy waste.

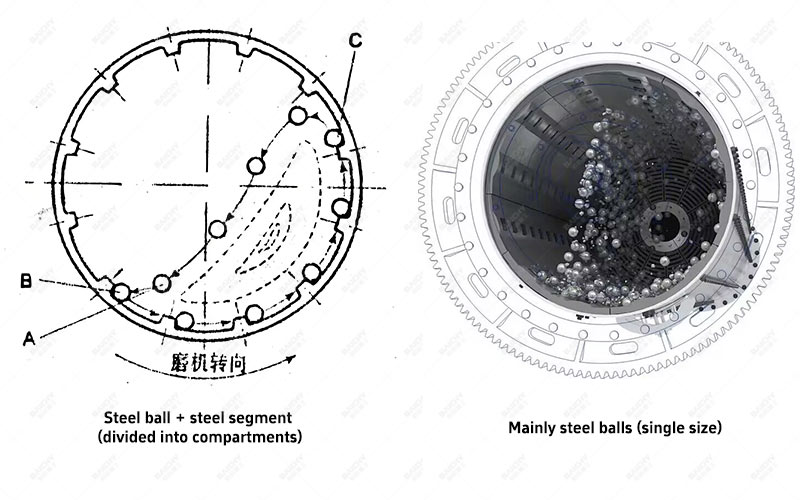

2. High-Efficiency Grinding System: Utilizing high-manganese steel liners and high-chromium alloy grinding balls, it boasts strong wear resistance, effectively reducing iron contamination while ensuring powerful impact and grinding force on the gold ore.

3. Stable and Reliable Operation: Equipped with a mature main bearing transmission system, it operates smoothly with a low failure rate, ensuring the continuity and stability of beneficiation operations and maximizing gold production.

4. Flexible Discharge Control: By adjusting the grinding media gradation and mill speed, the discharge particle size can be easily controlled to meet the requirements of subsequent processes such as cyanide leaching or flotation. 5. Excellent Cost-Effectiveness: As a classic model, this equipment boasts mature technology, relatively low purchase and maintenance costs, and a short investment recovery period, making it an ideal choice for gold mine investors.

III. Application of the 900x1800 Ball Mill in Gold Mine Beneficiation Process

This type of ball mill is typically placed after jaw crushers, cone crushers, and other coarse and medium crushing equipment for fine grinding of ores ≤25mm. The ground slurry enters classification equipment (such as spiral classifiers and hydrocyclones). Qualified fine particles enter the leaching or flotation system, while coarse particles are returned to the ball mill for further grinding, forming a closed-loop cycle to ensure grinding efficiency.

Choosing a suitable ball mill is the cornerstone of a successful gold mine beneficiation project. The 900x1800 gold mine ball mill stands out among many pieces of equipment due to its reliable performance, moderate processing capacity, and excellent economic efficiency. If you are planning or upgrading your gold mine beneficiation plant, this equipment is undoubtedly a highly efficient solution worthy of serious consideration.