In many industrial sectors, including building materials, chemicals, and metallurgy, material grinding is a core step in the production process. Whether preparing cement raw materials, glass raw materials, or various industrial fillers, stringent requirements are placed on the efficiency, stability, and finished product quality of grinding equipment. If you are looking for a ball mill capable of stably processing common minerals such as limestone, quartz, and volcanic ash, with an hourly output of 8-10 tons, this blog post will provide you with a comprehensive reference guide.

I. The Core Value of a Ball Mill with an 8-10 Ton/Hour Output

A ball mill with an 8-10 ton/hour output is a powerful performer among small to medium-sized grinding equipment. This output range is ideal for small to medium-sized building materials plants, chemical plants, ceramic plants, or specialized powder processing enterprises. It perfectly balances investment costs and production needs, meeting continuous production capacity requirements without excessive equipment idleness or energy waste.

For materials like limestone, quartz, and volcanic ash, their Mohs hardness typically ranges from 3 to 7 (limestone around 3, volcanic ash around 5-6, and quartz up to 7), encompassing both brittle and medium-to-high hardness materials. This necessitates ball mills with excellent adaptability and adjustability. Ball mills at this output level typically have a moderate cylinder length, ensuring sufficient residence time for thorough grinding. Furthermore, by adjusting the ratio of grinding media (steel balls) and rotation speed, they can easily handle materials of varying hardness.

II. Why are ball mills ideal for grinding limestone, quartz, and volcanic ash?

1. Wide Adaptability: Ball mills are typical "all-rounders." Whether it's relatively soft limestone, high-hardness and wear-resistant quartz, or potentially heterogeneous volcanic ash, ball mills can effectively grind them by adjusting process parameters. Their working principle makes them insensitive to fluctuations in material properties and ensures stable operation.

2. Excellent Finished Product Quality: Ball mills pulverize materials through a dual action of impact and grinding, producing powder particles with typically regular shapes, uniform particle size distribution, and adjustable fineness (usually reaching 80-400 mesh or even finer). This is crucial for subsequent mixing, reaction, or sale as a finished product.

3. Capacity for Handling Mixed Materials: In cement or new building material production, it is often necessary to mix limestone, volcanic ash, etc., in specific proportions before grinding. Ball mills are ideal for this process, ensuring thorough mixing of different components during grinding, achieving a high degree of homogenization—an advantage unmatched by many other crushing equipment.

III. Key Configuration and Operating Points for Achieving Optimal Output

To ensure your ball mill consistently and stably achieves its output target of 8-10 tons/hour, the following factors cannot be ignored:

• Model Matching: Typically, ball mills achieving this output have a cylinder diameter between 1.5 meters and 2.2 meters, and a length between 3 meters and 5.5 meters. Specific models (e.g., Φ1830×6400, Φ2100×4500, etc.) need to be determined in detail with the equipment supplier based on the feed particle size, grindability, and target fineness of the material.

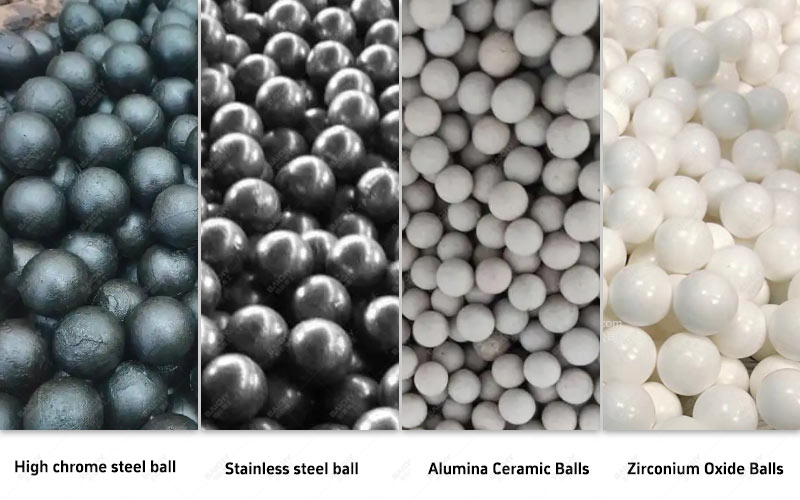

• Grinding Media Optimization: The size, material (high-chromium steel, low-carbon steel, etc.), and gradation (ratio of large to small balls) of the steel balls are crucial to efficiency and finished product. When grinding quartz, more large-diameter, high-hardness steel balls are needed to enhance impact force; while when grinding limestone, the proportion of medium- and small-diameter steel balls can be increased to improve grinding efficiency.

• Feeding System and Discharge Control: Stable feeding is fundamental. A reliable feeder must be provided to ensure that the material enters the mill uniformly and continuously. Simultaneously, the screening device at the discharge end (e.g., single-layer partition plates, discharge grates) must ensure that qualified fine powder is discharged in a timely manner to avoid "over-grinding," which is a crucial link in ensuring high output.

• System Matching: Ball mills never operate in isolation. A front-mounted jaw crusher (crushing large materials to below 25mm), a rear-mounted elevator, conveyor, and dust collector together constitute a highly efficient grinding system. A well-designed system ensures that production targets are met.

IV. Application Scenarios

This 8-10 ton/hour ball mill is a reliable foundation for starting a business or expanding production. It can be used for:

• Cement production: Grinding limestone, volcanic ash (as an admixture), gypsum, and other raw materials.

• Mineral powder processing: Producing limestone powder, quartz powder, and volcanic ash powder for concrete admixtures.

• Ceramics and glass industry: Preparing quartz powder, feldspar powder, and other raw materials.

• Chemical fillers: Producing calcium carbonate (limestone) powder and silica fume (quartz) powder of various finenesses.

Choosing a suitable ball mill is the first step to successful investment. A ball mill with a capacity of 8-10 tons per hour, with its moderate size, strong material adaptability, and stable powder output quality, is the golden choice for processing materials such as limestone, quartz, and volcanic ash. Through scientific selection, reasonable configuration, and meticulous maintenance, it will undoubtedly become the core driving force for value creation on your production line.