Driven by the continued growth in demand from industries such as building materials, mold manufacturing, food, and medical supplies, the market prospects for gypsum powder are very broad. For companies planning to expand their production scale, building a highly efficient, stable, and automated gypsum powder production line is key to enhancing their core competitiveness.

This article will focus on the classic capacity specification of "5 tons/hour," providing a comprehensive analysis of the composition and advantages of a gypsum powder production line.

I. Core Process Flow of a 5-ton/hour Gypsum Powder Production Line

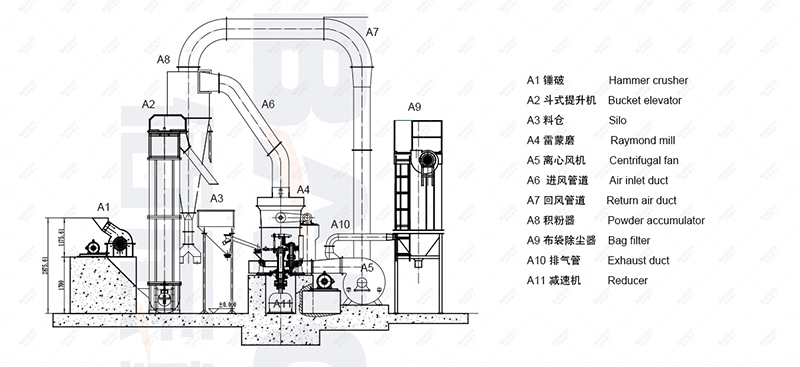

A standardized gypsum powder production line aims to transform natural gypsum stone or industrial by-product gypsum into gypsum powder of varying fineness and properties through processes such as crushing, grinding, calcination, and cooling. Its basic process is as follows:

1. Crushing Stage: Large pieces of gypsum ore are first coarsely crushed by a jaw crusher to a smaller particle size (usually <8cm), preparing for subsequent grinding.

2. Grinding Stage: The crushed gypsum particles are fed into a grinding mill by a bucket elevator for fine grinding. This is the core step that determines the fineness of the gypsum powder.

3. Calcination Stage: The ground gypsum powder is fed into a calcination furnace (such as a fluidized bed furnace or rotary kiln), where it is dehydrated at a suitable temperature to become calcined gypsum (hemihydrate gypsum).

4. Cooling and Aging: The calcined gypsum powder is at a high temperature and needs to be cooled by a cooling system and undergo short-term aging to stabilize its properties.

5. Packaging Stage: The final product is weighed and packaged by an automated packaging machine and stored for sale.

II. Recommended Core Equipment Configuration (5 tons/hour)

To achieve a stable output of 5 tons/hour, the core equipment of the production line needs to be scientifically selected:

• Crushing Equipment: A PE-400×600 jaw crusher is recommended, as its processing capacity fully meets the requirements.

• Grinding Equipment: This is the "heart" of the production line. European-style mills (such as the MTW series) or vertical mills are recommended. These types of equipment have low energy consumption, high output, a wide range of adjustable fineness (usually adjustable between 80-400 mesh), and a high degree of automation.

• Calcination Equipment: For a production capacity of 5 tons/hour, a high-efficiency and energy-saving fluidized bed calcining furnace is recommended. This equipment boasts high thermal efficiency and precise temperature control, producing high-quality building gypsum powder.

• Supporting Equipment: Includes an electromagnetic vibrating feeder, bucket elevator, screw conveyor, pulse dust collector, and automated packaging machine, forming a complete and environmentally friendly closed-loop system.

III. Significant Advantages of Choosing a 5-ton/hour Gypsum Powder Production Line

1. Significant Economies of Scale: Based on an 8-hour workday, daily output can reach 40 tons, effectively meeting the order demands of medium to large-sized customers and rapidly capturing market share.

2. High Degree of Automation: From feeding to packaging, the entire line can be automated or semi-automated, significantly reducing labor costs and operational errors.

3. Stable Finished Product Quality: Professional equipment configuration ensures uniform grinding fineness and stable calcination process, guaranteeing consistent final product quality.

4. Environmental and Energy-Saving Compliance: The production line is equipped with a high-efficiency dust removal system, with dust emissions far below national environmental standards, achieving green production.

IV. Investment Analysis and Conclusion

The price of investing in a 5-ton/hour gypsum powder production line varies depending on factors such as equipment selection, automation level, and manufacturer brand. Investors are advised to consider long-term returns and choose equipment manufacturers with mature technology and comprehensive after-sales service.

In conclusion, a scientifically designed 5-ton/hour gypsum powder production line is not only a powerful tool for increasing production capacity but also an important step for enterprises to achieve industrial upgrading and move towards high-quality development. Choosing a reliable partner and customizing solutions that match your raw materials and product positioning will be key to your success.