In the mineral processing and aggregate production industry, a 50 TPH (50 tons per hour) capacity is a very classic and highly sought-after option. It balances investment costs with output efficiency, making it suitable for small and medium-sized quarries, concrete batching plants, and aggregate production supporting large-scale infrastructure projects. This article will delve into the price structure, core advantages, and application scenarios of a 50 TPH stationary crushing plant, providing you with comprehensive decision-making references.

Capacity Overview: Why is 50 TPH so popular?

A 50 TPH capacity means that, under ideal working conditions, this crushing production line can process and produce approximately 50 tons of finished aggregate per hour. This scale is just right:

Moderate investment threshold: Compared to production lines with capacities of hundreds of tons or more, its equipment investment, infrastructure costs, and power consumption are more controllable, resulting in a shorter return on investment period.

Meets diverse needs: The output is sufficient to supply the needs of small and medium-sized commercial concrete plants, road construction, water conservancy projects, and regional building materials markets.

Flexible layout: The production line configuration is relatively compact, and the requirements for site area are not as stringent as those for million-ton-level production lines, making it easy to plan and install within existing mining areas or industrial land.

Price Analysis: Core Factors Affecting the Price of a 50 TPH Stationary Crushing Plant

The "price of a 50 TPH stationary crushing plant" is not a fixed number; its price range typically varies from US$150,000 to US$500,000, or even higher. The price difference mainly stems from the following variables:

Equipment configuration and brand: This is the most significant factor. The cost difference is significant between using core main machines from international top brands and using high-quality domestic or joint-venture brands. Whether the configuration includes a single jaw crusher + impact crusher/cone crusher, or also includes feeders, vibrating screens, conveyors, and dust removal systems, directly affects the total price.

Raw material characteristics and finished product requirements: The selection of equipment (such as the necessity of a cone crusher) and the grade of wear-resistant parts differ when crushing high-hardness granite and basalt compared to crushing limestone and bluestone, affecting the price. The higher the requirements for finished product particle shape and gradation (such as the need for manufactured sand), the more complex the process, and the higher the investment. Automation and Environmental Protection Levels: The price difference is significant between basic electrically controlled systems and production lines equipped with fully automatic control systems, central lubrication, and advanced dust control and noise reduction devices.

"Turnkey" Project Scope: Does the price only include the equipment, or does it cover basic design, steel structure platforms, installation and commissioning, technical training, and subsequent operational support?

Core Advantages: Why choose a stationary crushing production line?

Compared to mobile crushing plants, stationary crushing production lines have irreplaceable advantages in specific scenarios:

Higher Stability and Capacity: The equipment has a solid foundation, enabling continuous high-intensity operation for extended periods, making it easier to achieve stable and efficient full-load production, and typically resulting in lower energy consumption per unit of output.

Superior Product Quality and Process Flexibility: Stationary lines are easy to design with multi-stage crushing and multi-stage screening closed-loop systems, allowing for more precise control of the finished product's particle shape and more flexible adjustment of the grading, especially suitable for commercial concrete and high-grade building materials with strict aggregate quality requirements.

Lower Long-Term Operating Costs: The equipment is centrally installed, facilitating maintenance; the conveying distance is fixed, resulting in high efficiency and low wear of the belt conveyor; over its lifecycle, its overall operating cost (OPEX) is often more advantageous.

Stronger Economies of Scale: For mines with large resource reserves and long mining cycles (more than 3-5 years), a stationary line is the most cost-effective option.

| Key Words |

Is a 50 TPH Stationary Crushing Plant the Most Cost-Effective Solution for Your Medium-Scale Quarry? |

| Product Model |

Stone Crushing Plant |

| Capacity |

0-2000t/h |

| Core Advantages |

Multi-stage fragmentation and reshaping |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Classic Application Case Studies

Case Study 1: Southeast Asia Limestone Aggregate Project

Raw Material: Limestone, compressive strength <150MPa

Finished Products: 0-5mm, 5-10mm, 10-20mm three specifications of aggregates

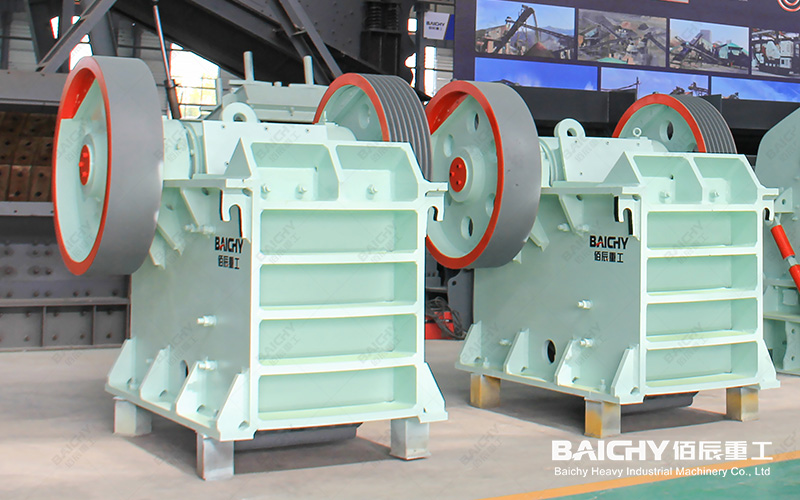

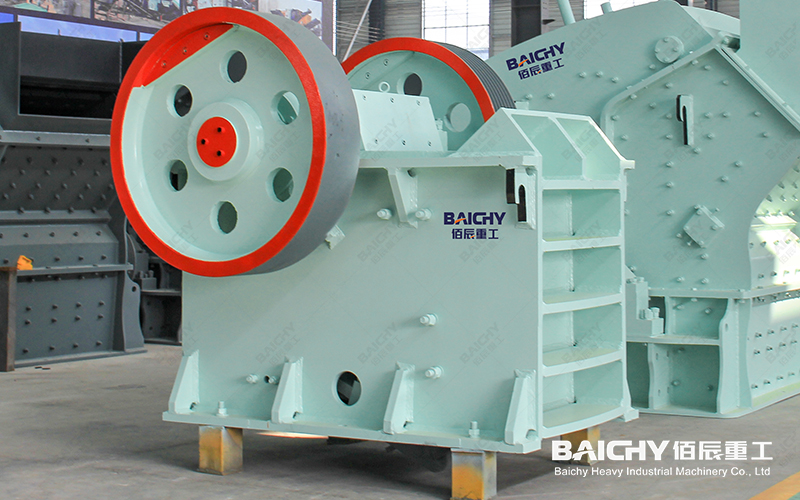

Core Configuration: Vibrating feeder + PE400×600 jaw crusher + PF1214 impact crusher + 3YK1548 vibrating screen + belt conveyor system

Features: Economical investment, compact layout, excellent finished product particle shape, meeting the needs of local commercial concrete plants. Case Study Two: North China Granite Sand Production Project

Raw Material: Granite, compressive strength > 180MPa

Finished Products: 0-5mm high-quality manufactured sand, 10-31.5mm road base aggregate

Core Configuration: Vibrating feeder + C80 jaw crusher + HST160 single-cylinder hydraulic cone crusher + VSI9526 sand making machine + multi-layer vibrating screen + sand washing machine

Features: For high-hardness rocks, the "cone crusher + sand making machine" process is used to ensure production capacity and finished product quality. The manufactured sand has excellent gradation and high added value.

Equipment Selection Recommendations

Based on different rock hardness and investment budgets, we recommend the following two mainstream configuration schemes:

Economical Configuration (for medium to low hardness rocks):

Process Flow: Jaw crusher (coarse crushing) + impact crusher (medium and fine crushing) + vibrating screen (screening).

Features: Low investment, simple process, easy maintenance, and the finished product has a cubic shape, but the wear parts consume relatively quickly.

High-Efficiency and Durable Configuration (for high-hardness rocks/pursuing low operating costs):

Process Flow: Jaw crusher (coarse crushing) + hydraulic cone crusher (medium and fine crushing) + impact sand making machine (shaping and sand making optional) + vibrating screen (screening).

Features: Higher initial investment, but strong equipment wear resistance, low long-term operating costs, especially suitable for severe wear conditions, and excellent control over finished product gradation.

Frequently Asked Questions (FAQ)

Q1: What non-equipment costs need to be considered when building a complete 50 TPH fixed crushing production line?

A1: In addition to the equipment itself, you will need to budget for: equipment foundation concrete pouring, steel structure platform construction, silo construction, plant electrical engineering (cables, transformers), environmental protection facilities (spraying, dust removal, sound insulation), installation and commissioning costs, and possible spare parts inventory. These "supporting facilities" costs may account for 20%-40% of the equipment cost.

Q2: How long does it generally take from signing the contract to the production line being put into operation?

A2: This depends on the complexity of the configuration. Typically, the equipment manufacturing cycle is 1-3 months; on-site civil construction takes 1-2 months; and installation and commissioning take about 1 month. Overall, for a standard project from start to commissioning, it is recommended to allow 4-7 months.

Q3: Can a fixed production line be relocated or upgraded in the future?

A3: Yes, but the cost is high. The design of a fixed line can incorporate future expansion by reserving interfaces and space. Relocation is a complex undertaking, involving equipment dismantling, transportation, and re-installation and commissioning at the new site, which is quite expensive. Therefore, fixed lines are more suitable for long-term, fixed resource locations.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!