In aggregate production, 5-19mm pea gravel and crushed stone aggregates are intermediate-sized products with extremely high market demand, widely used in concrete preparation, foundation backfilling, and road base construction. To achieve stable and efficient production of aggregates within this specific particle size range, selecting suitable crushing and screening equipment is crucial. This article will systematically outline which equipment is best suited for processing 5-19mm materials.

I. Why is the 5-19mm size so important?

5-19mm aggregates, due to their uniform particle size, moderate angularity, controllable powder content, and good gradation and compaction, are key to forming a high-quality concrete skeleton. The core requirements for producing this type of product are "control" and "screening."

• Control: Precisely control the crushing force and output particle size to avoid over-crushing and producing excessive powder, and also to prevent excessively large particle sizes.

• Screening: Efficiently separate the crushed mixture according to strict standards (5-19mm).

II. Which equipment is capable of producing 5-19mm aggregates?

A complete production line typically includes several stages: coarse crushing, medium and fine crushing, and screening. The following are the most critical pieces of equipment for producing 5-19mm aggregate:

1. Medium and Fine Crushing Core Equipment: Key to Determining Output Particle Size

• Cone Crusher: High-Capacity Choice

◦ Advantages: Suitable for medium to high hardness materials, employing a layered crushing principle, high crushing efficiency, excellent product particle shape (cubic), and long service life of wearing parts. The discharge opening can be precisely controlled by adjusting the hydraulic system or replacing the liners, making it the mainstream equipment for producing 5-19mm aggregate.

◦ Applicable Scenarios: Large-scale sand and gravel aggregate production lines, projects with high requirements for capacity and product particle shape.

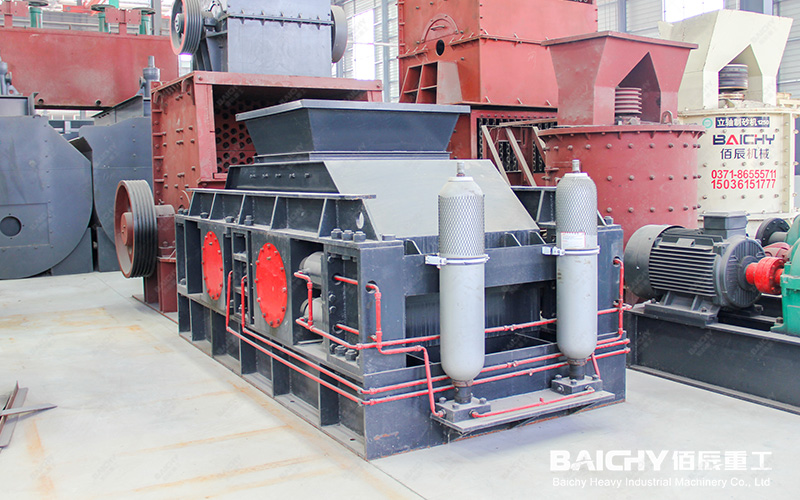

• Double Roll Crusher: Precise Particle Size Control Choice

◦ Advantages: By adjusting the gap between the two rollers, the output particle size can be controlled very precisely, with less "over-crushing," producing uniform pea gravel particles. Particularly suitable for processing materials with medium to low hardness.

◦ Applicable Scenarios: Small to medium-sized projects with extremely high requirements for product particle size uniformity and raw material hardness not exceeding a certain level.

• Impact Crusher: The Choice for Particle Shape Optimization

◦ Advantages: Utilizes the impact crushing principle, producing good particle shape with fewer sharp edges, closer to the rounded shape of a "pea." However, it may produce slightly more powder than a cone crusher.

◦ Applicable Scenarios: Emphasis is placed on the aesthetic appearance of aggregate particles, with raw material hardness at a moderate level.

2. Core Screening Equipment: The "Gatekeeper" Ensuring Precise Specifications

• Vibrating Screen: An Indispensable Grading Tool

◦ Regardless of the crushing equipment used, a vibrating screen (such as a circular vibrating screen or a linear vibrating screen) must be installed. It grades the crushed mixture through multiple layers of screens with different specifications. For a 5-19mm requirement, the upper screen mesh size can be set to 19mm, and the lower layer to 5mm, thus accurately screening out qualified products. Particles larger than 19mm are returned to the crusher for further crushing, while particles smaller than 5mm are sold as fine aggregate or stone powder.

3. Pre-processing Equipment: Laying the Foundation for Subsequent Stages

• Jaw Crusher: Typically used as a coarse crusher, responsible for crushing large pieces of raw stone to a medium size (e.g., below 100-200mm), providing suitable feed for subsequent medium and fine crushing equipment. It does not directly determine the final product's fineness, but it is the "first hurdle" in the entire production line.

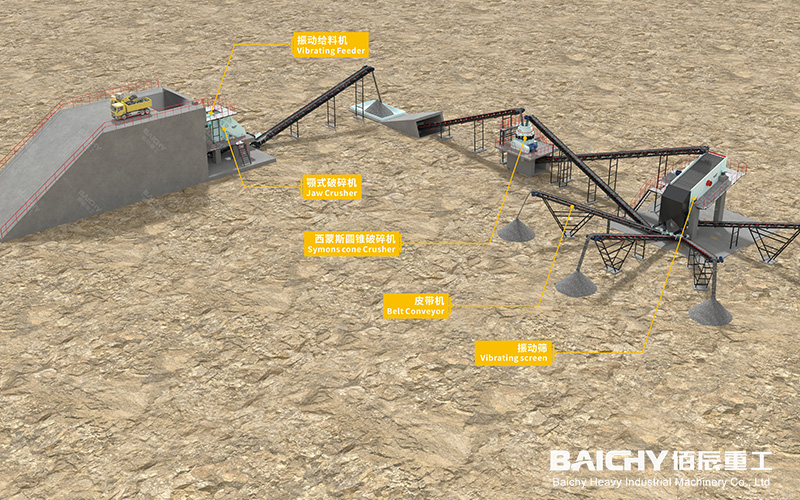

III. Recommended Classic Production Line Flow

A typical flow for efficiently producing 5-19mm pea gravel is as follows: Feeder → Jaw Crusher (coarse crushing) → Cone Crusher/Roll Crusher (medium and fine crushing) → Vibrating Screen (screening) → Belt Conveyor (conveyor and return material)

• Flow Summary: After coarse crushing by the jaw crusher, the raw material undergoes medium and fine crushing by the cone crusher or roll crusher. The crushed material is then conveyed to the vibrating screen. The material exceeding the screen size (>19mm) is returned to the fine crusher for further crushing, forming a closed-loop cycle; the material passing through the screen (5-19mm) is the desired pea gravel product; material <5mm is collected as fine material.

The key to selecting equipment capable of discharging 5-19mm pea gravel lies in the precise coordination between the selection of medium and fine crushing equipment and the screening system. For users seeking high capacity and hard materials, a "jaw crusher + cone crusher + vibrating screen" combination is ideal; for users who particularly emphasize particle size uniformity and control of powder content, a "jaw crusher + roller crusher + vibrating screen" combination is superior. It is recommended to conduct a comprehensive evaluation based on your raw material characteristics, capacity requirements, and investment budget to select the most suitable equipment combination.