In today's booming infrastructure industry, the demand for high-quality manufactured sand is strong. River pebbles, as a high-quality natural stone with high hardness, strong compressive strength, and low mud content, are an ideal raw material for producing high-quality manufactured sand.

A scientifically designed and rationally configured river pebble sand production line is key to ensuring sand quality, controlling operating costs, and achieving economic benefits.

This article will provide an in-depth analysis of the core components and advantages of a 100-ton-per-hour river pebble sand production line.

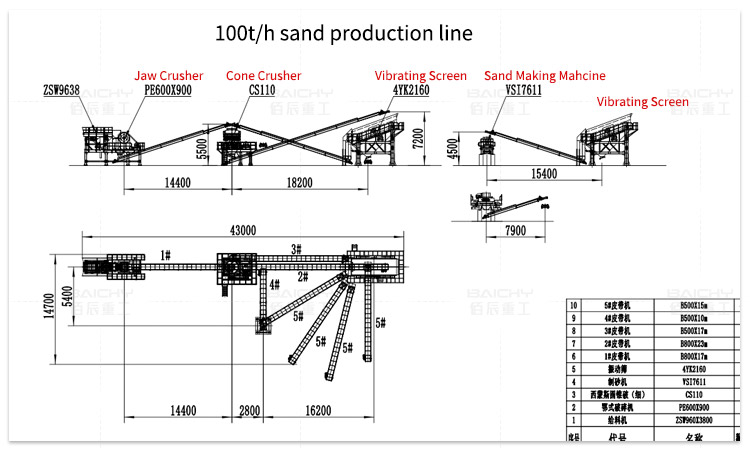

I. Core Process Flow of the Production Line

An efficient river pebble sand production line is not simply a collection of individual pieces of equipment, but a systematic project. Its typical flow is as follows:

1. Feeding Stage: The vibrating feeder uniformly and continuously feeds the river pebble raw material into the next process, avoiding blockage in the jaw crusher, and is the "first step" for stable production.

2. Coarse Crushing Stage: Large pieces of river pebble are first subjected to primary crushing by a jaw crusher. Its powerful crushing force and high stability can crush irregularly shaped large pieces of river pebble to a medium particle size.

3. Medium and Fine Crushing Stage: The coarsely crushed stone is conveyed by a belt conveyor to a cone crusher or impact crusher for medium and fine crushing. Due to the high hardness and abrasion of river pebbles, a cone crusher based on the principle of layered crushing is recommended, as it offers longer wear-resistant component life and lower operating costs.

4. Sand Making Stage (Core): This is the crucial step determining the quality of the finished sand. The medium and finely crushed stone enters a vertical shaft impact crusher. Through the principle of "stone against stone" or "stone against iron," crushing, shaping, and grinding are carried out, ultimately producing high-quality manufactured sand with rounded particle shape and reasonable gradation.

5. Screening Stage: A vibrating screen classifies the crushed material. Sand that meets the finished product particle size requirements is screened out, while oversized stones are returned to the crusher for further crushing, forming a closed-loop cycle to ensure precise control of the finished product yield and particle size.

6. Environmental Protection Stage (Optional): Equipping the sand washing machine can effectively remove trace amounts of stone powder and impurities from the finished sand, improving the sand grade and meeting the requirements for high-standard construction sand. Simultaneously, dust removal and noise reduction equipment can be configured to achieve green production.

II. Recommended Configuration of Core Equipment for a 100-ton-per-hour Production Line

| Equipment Name | Recommended Model (Example) | Main Function | Advantages |

| Vibrating Feeder | GZD960×3800 | Uniform feeding, pre-screening | Ensures stable operation of subsequent equipment and improves overall line efficiency |

| Jaw Crusher | PE600×900 | Primary coarse crushing | Large feed opening, strong crushing force, large processing capacity |

| Cone Crusher | HP200 | Medium and fine crushing | Good wear resistance, suitable for high-hardness materials, low operating cost |

| Vertical Shaft Impact Sand Making Machine | VSI-1140 | Sand making and shaping | Excellent finished product particle shape, controllable powder content, high sand yield |

| Circular Vibrating Screen | 3YK2160 | Grading and screening | Multi-layer screen, high screening efficiency, strong processing capacity |

| Sand Washing Machine | XS3020 | Cleaning and impurity removal | Enhancing Sand Cleanliness and Market Value |

Note: The above is a general configuration scheme. Actual selection requires customized design based on the specific particle size, hardness, and output requirements of the river pebbles.

III. Significant Advantages of the Production Line

• High Efficiency and High Output: Scientific layout, high equipment matching, stable and reliable 100 tons per hour production, easily meeting the sand supply needs of large-scale projects.

• Superior Quality: The produced manufactured sand has a polyhedral particle shape, continuous and stable gradation, and high crushing value, completely replacing natural sand for high-grade concrete.

• Durable and Energy-Saving: Core crushing equipment is optimized for high-hardness materials, and wear-resistant parts use high-strength alloys, resulting in a long service life and effectively reducing the cost per ton.

• Environmentally Friendly and Economical: Can be equipped with dust removal and water circulation systems to achieve zero emissions of dust and wastewater. Turning seemingly useless river pebbles into valuable resources yields significant economic benefits.

Investing in a 100-ton-per-hour river pebble sand production line is not only a wise move to meet market demand but also a long-term strategy for resource value-added and sustainable development. Choosing an experienced and technically proficient equipment supplier to provide you with one-stop service, from site planning and equipment selection to installation, commissioning, and after-sales maintenance, is a crucial guarantee for project success.

Feel free to contact us anytime for a customized river pebble sand making production line configuration plan and detailed quotation!