For both new and existing clients planning to enter the sand and gravel aggregate industry or upgrading their existing production lines, a well-designed, stable, and high-return crushing production line is crucial for success. Among these, a 20-ton-per-hour capacity line is particularly favored by small and medium-sized stone quarries and engineering projects due to its moderate investment and high flexibility.

So, what core equipment is needed to build such a production line? What are its specifications and key selection criteria? This article will provide you with a detailed equipment list and specification analysis to help you make informed decisions.

Core Equipment 1: Jaw Crusher – The “Powerful Pioneer” of the Production Line

As the first stage in stone crushing, the jaw crusher is responsible for the primary crushing (coarse crushing) of large raw materials. Its powerful crushing force and robust structure make it an ideal choice for processing hard materials such as granite, basalt, and river pebbles.

PE250x400 Jaw Crusher

PE400x600 Jaw Crusher

• Recommended Model: PE-250×400 or PE-400×600

• Feed Inlet Size: 250×400mm or 400×600mm (selectable based on maximum raw material particle size)

• Maximum Feed Particle Size: 210mm or 340mm

• Discharge Inlet Adjustment Range: 20-80mm

• Processing Capacity: Approximately 5-20 tons/hour (requires downstream equipment to achieve a stable output of 20 tons/hour)

• Matching Motor Power: 15-30kW

Selection Considerations: Ensure the jaw crusher's feed inlet size is slightly larger than the maximum size of your raw material to avoid material jamming. The PE-400×600 model is a more reliable choice for achieving a production capacity of 20 tons/hour, providing sufficient raw materials for subsequent processes.

Core Equipment Two: Cone Crusher/Impact Crusher – The “Fine Processing Expert” for Medium and Fine Crushing

After coarse crushing by a jaw crusher (particle size typically between 100-300mm), the stone needs to be fed into a secondary crushing unit for medium and fine crushing to achieve the desired aggregate size. There are two main options, which should be determined based on the material characteristics:

PYB900 Cone Crusher

• Option A: Cone Crusher (Suitable for high-hardness, highly abrasive materials)

◦ Recommended Models: HPC series or CH series small cone crushers

◦ Features: Employs the principle of layered crushing, resulting in long wear-resistant parts life and good finished product particle shape, but the price is relatively high.

◦ Feed Size: ≤160mm

◦ Processing Capacity: Can precisely match needs of 20-50 tons/hour.

• Motor Power: Approx. 55-90kW

PF1007 Impact Crusher

• Option B: Impact Crusher (Suitable for medium to low hardness materials, prioritizing cost-effectiveness)

• Recommended Models: PF-1010 or PF-1210

• Features: Impact crushing principle, produces cubic particles with excellent gradation, and is economical.

• Feed Size: ≤250mm

• Processing Capacity: Up to 30-80 tons/hour, easily meeting demand.

• Motor Power: Approx. 55-110kW

Selection Considerations: For crushing hard rocks such as granite and basalt, cone crushers are preferred due to their lower long-term operating costs; for crushing medium to hard materials such as limestone and bluestone, impact crushers offer better cost-effectiveness.

Core Equipment Three: Vibrating Screen – The Grading Master of Aggregates

The crushed mixture needs to be graded by a vibrating screen to separate finished materials of different specifications (e.g., 0-5mm, 5-10mm, 10-20mm, etc.).

• Recommended Model: Double-layer circular vibrating screen such as 2YK1237 or 2YK1548

• Number of Screen Layers: 2 or 3 layers

• Screen Area: Selected based on throughput and screening efficiency; should be slightly larger than the crusher's capacity to allow for margin.

• Screen Aperture Size: Can be customized according to the customer's required finished product specifications (e.g., 5mm, 10mm, 20mm square hole screens).

Selection Points: The processing capacity of the vibrating screen must be greater than or equal to the total capacity of the upstream crusher; otherwise, it will become a production bottleneck, leading to incomplete screening or clogging.

Auxiliary Equipment: The Indispensable Production Line Network

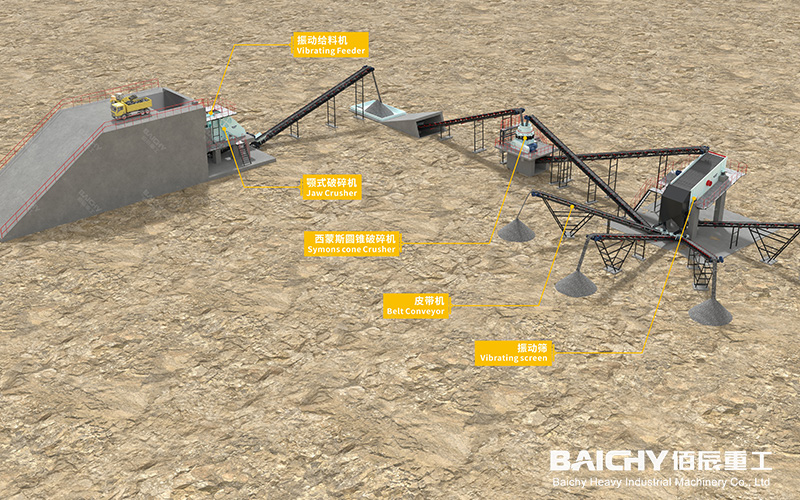

A complete production line also relies on the following auxiliary equipment, which together form a smooth network system:

1. Feeder (e.g., ZSW series vibrating feeder): Evenly and continuously feeds raw materials from the hopper into the jaw crusher, preventing idling or overloading, acting as a metronome for stable production.

2. Belt Conveyors (Multiple): Connects various main equipment, undertaking the task of horizontal or inclined material transport. Its bandwidth and speed must match the processing capacity.

3. Electrical Control System: Centrally controls the start-up, shutdown, interlocking, and protection of the entire production line, achieving automated operation and ensuring equipment and personnel safety.

Example Configuration Scheme for a 20-ton/hour Stone Crushing Production Line

• Scheme 1 (For High-Hardness Rock):

◦ Process: Vibrating Feeder → Jaw Crusher (PE-400×600) → Cone Crusher (Small Model) → Vibrating Screen (2YK1237) → Finished Product Stockpile. • Option 1 (for medium to low hardness rocks):

Process: Vibrating feeder → Jaw crusher (PE-400×600) → Impact crusher (PF-1010) → Vibrating screen (2YK1548) → Finished product stockpile.

Option 2 (for medium to low hardness rocks):

Process: Vibrating feeder → Jaw crusher (PE-400×600) → Impact crusher (PF-1010) → Vibrating screen (2YK1548) → Finished product stockpile.

Option 3 (for rocks): Low investment cost, quick installation, good finished product shape.

The configuration of a 20-ton-per-hour stone crushing production line is not fixed. The key is to customize the design based on your raw material properties, finished product specifications, budget, and site conditions. Choosing a reliable equipment supplier and obtaining professional process solutions is a crucial step in ensuring project success and long-term profitability. We hope this detailed equipment list and specifications will provide a valuable reference for your initial planning.