In many industrial sectors such as building materials, chemicals, metallurgy, and environmental protection, material drying is a crucial step in the production process. When processing large quantities of loose granular materials like sand, quartz sand, and slag, the rotary sand dryer (also commonly known as a drum dryer) is undoubtedly one of the most widely used and cost-effective core pieces of equipment.

With its powerful processing capacity, stable operating performance, and wide adaptability, it has become the preferred choice for many enterprises.

I. What is a Rotary Sand Dryer?

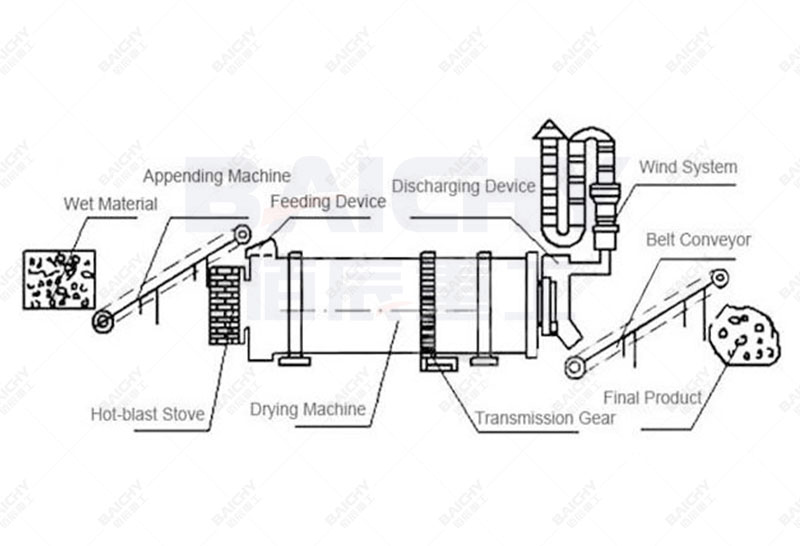

A rotary sand dryer is a large, slightly inclined, slowly rotating metal drum. Wet material enters from one end of the drum and, under the continuous tumbling of the lifters inside, comes into full contact with the high-temperature medium (hot air, flue gas, etc.) from the hot air furnace, undergoing effective heat exchange and evaporating moisture. Finally, the dried material exits from the other end of the drum, achieving continuous industrial production.

II. Core Working Principle: Countercurrent Heating and Lifting Plate Tilting

Its secret to efficient drying lies in two key designs:

1. Countercurrent Heating Principle: Normally, wet material enters from the higher end of the drum, while hot air flows countercurrently from the lower end. This countercurrent contact method ensures that the wettest material encounters the cooler, higher-humidity exhaust air, while the dry material about to be discharged comes into contact with the hottest, lowest-humidity air. This avoids damage to the dry material due to overheating and maximizes thermal efficiency, ensuring uniform drying.

2. Lifting Plate System: The inner wall of the drum is equipped with various types of lifting plates. As the drum rotates, the lifting plates continuously lift and scatter the material, forming a uniform material curtain in the hot air. This greatly increases the contact area between the material and the hot air, accelerating moisture evaporation and preventing material clumping or uneven drying.

III. Key Advantages of the Rotary Sand Dryer

• Large Processing Capacity, Continuous Operation: Capable of 24-hour continuous operation, particularly suitable for large-scale, industrial production needs.

• High adaptability: Capable of handling sand and gravel materials with different particle sizes and initial moisture contents, with stable and reliable operation.

• Excellent drying effect: Thanks to the counter-current principle and flipping plates, the finished product has a uniform and stable moisture content, fully meeting the requirements of subsequent processes.

• Low operating cost: Simple structure, convenient maintenance, high thermal efficiency, and significant long-term cost advantages.

• Optional dust removal device: Can be easily connected to a bag filter or cyclone dust collector to meet environmental emission standards.

IV. Main Application Industries

• Dry-mixed mortar industry: Drying natural or manufactured sand; essential equipment for producing mortar, putty powder, and other products.

• Foundry industry: Drying quartz sand, water glass sand, etc. used in foundrying.

• Building materials industry: Drying raw materials such as slag, clay, and coal powder.

• Chemical industry: Drying fertilizers, pelleted feed, etc.

• Environmental protection industry: Drying waste such as sludge and straw.

V. How to Choose a Suitable Rotary Sand Dryer?

When selecting equipment, the following points should be considered:

• Initial moisture content and target moisture content: These are crucial in determining the drum size and heat source power.

• Hourly output requirements: Directly related to the size of the equipment model.

• Material characteristics: Such as particle size, viscosity, and temperature resistance.

• Heat source selection: Gas, oil, coal, biomass pellets, or steam can be selected based on site conditions.

As a classic industrial drying equipment, the rotary sand dryer continuously safeguards the production efficiency and quality improvement of various industries with its superior performance and reliability. If you are facing the challenge of drying sand and gravel materials, choosing a suitable rotary dryer is undoubtedly an important step towards efficient production.

Welcome to contact us; our technical experts will provide you with the most professional equipment selection and solutions based on your specific needs!