Basalt crushing, basalt crushing process, basalt crushing production line

Project Introduction: Basalt Crushing Production Line

Basalt properties

Basalt is a good raw material for the production of "cast stone". "Cast stone" is a material made of basalt after melting, casting, crystallization, and annealing. It is harder and more resistant than alloy steel and more resistant to corrosion than lead and rubber. Basalt also acts as a "lubricant" in a steel casting process, which can prolong the life of the cast film. At the same time, basalt can also be drawn into glass wool, which is stronger in alkali resistance and performance than ordinary glass wool cloth. Among them, porous basalt, also known as pumice, has many pores and is hard in texture. It can be mixed in concrete to reduce its weight of concrete. It is not only strong but also has the characteristics of sound insulation and heat insulation. Good aggregate for concrete.

Basalt crushing process

The Mohs hardness of basalt reaches 5-7, and the SiO2 content is 45%-52%. Therefore, impact crushers are generally not used for basalt crushing, and cone crushers are mostly used for secondary and tertiary crushing operations.

Production line basalt crushing process, basalt crushing production line

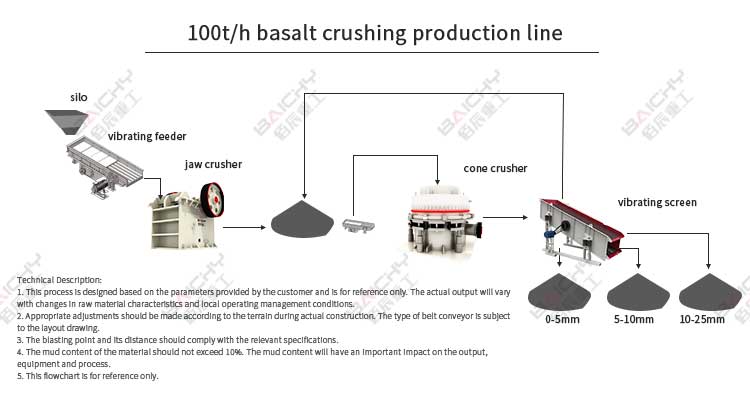

100-150tph basalt crushing production line

Zimbabwe Live

| Product Name | Quantity |

| Silo | 1 |

| Vibrating feeder | 1 |

| Jaw crusher | 1 |

| Cone crusher | 1 |

| Vibrating screen | 1 |

| Belt conveyor | 7 |

Process flow

The basalt raw material enters the PE600x900 jaw crusher through the feeder for primary crushing, enters the hp300 multi-cylinder hydraulic cone crusher through the belt conveyor for secondary crushing, and screens 30-70 through the vibrating screen as the finished ballast stone for high-speed rail; 0-18MM enters After being crushed by a machine, it is screened, 0-5 is sand, and 5-18mm is used as road fabric.

Advantages of equipment configuration

1. The output grain shape is good, and the aggregate quality is high;

2. The output of fine aggregate and fine aggregate can be adjusted according to demand;

3. Aggregate and sand-making can be converted.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)