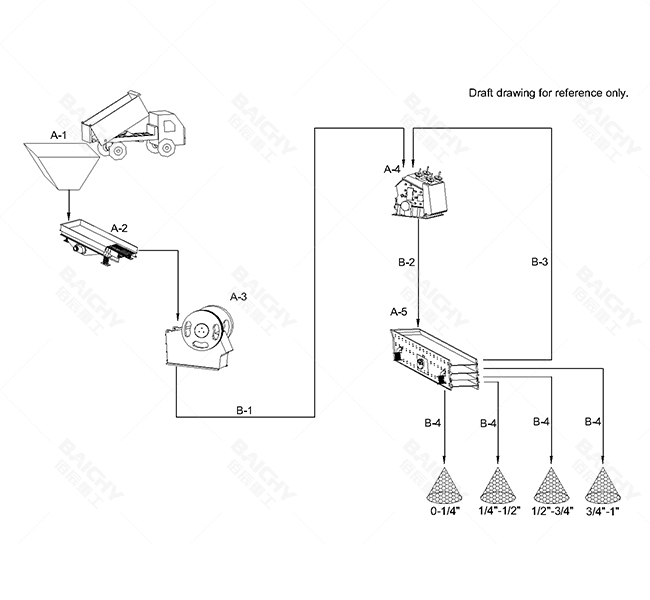

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW650X2500 | 1 |

| A-3 | Jaw Crusher | PE400X600 | 1 |

| A-4 | Impact Crusher | PF1007 | 1 |

| A-5 | Vibrating Screen | 4YK1237 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B500 | 18m | 1 |

| B-2 | B650 | 22m | 1 |

| B-3 | B500 | 23m | 1 |

| B-4 | B500 | 15m | 4 |

Tailored specifically for small and medium-sized quarries and aggregate plants, this system provides a one-stop, end-to-end solution from feeding to finished product grading. Through modular design and efficient capacity matching, we help you overcome production bottlenecks with minimal investment, stably produce high-quality aggregates, and maximize your return on investment.

In the field of sand and aggregate, mining crushing, and construction waste recycling, our 30-50 t/h medium-sized crushing production line has become the ideal choice for small and medium-sized aggregate plants and engineering projects, thanks to its three core advantages: high efficiency and energy saving, flexible adaptability, and superior finished product quality.

• Utilizing the "PE400×600 jaw crusher + PF1007 impact crusher" optimal combination, it offers a high crushing ratio and low energy consumption, reducing system power consumption by approximately 20% compared to traditional processes.

• Significantly reduces per-ton production costs and increases profit margins.

• The aggregates crushed by the impact crusher are multi-faceted and cubic, with a needle-like and flaky content of less than 8%, and a continuous gradation, fully meeting national standards for construction aggregates.

• The finished product is highly competitive and favored by commercial concrete plants and asphalt plants.

• It can process various hard rocks such as granite, basalt, and limestone, and can also efficiently process construction waste by adjusting the crusher parameters.

• One machine for multiple uses, adapting to market changes and expanding business scope.

• Integrated control of feeding, screening, and conveying, supporting centralized start/stop and fault warning; the entire line can be operated by only 1-2 people. Reduce reliance on manual labor, improve operational stability, and safety

① Applicable materials: Granite, basalt, river pebbles, limestone, etc.

② Finished product specifications: 0-5mm (high-quality manufactured sand), 5-10mm, 10-20mm, 20-31.5mm and other multi-grade aggregates

③ Application areas: Commercial concrete mixing plants, asphalt mixing plants, precast concrete factories, highway and railway base materials

④ Solution features: Closed-circuit crushing and screening, adjustable grading, controllable particle shape, meeting the requirements of national standard Zone II medium sand

① Applicable scale: Suitable for small and medium-sized mines and quarries with an annual output of 300,000-500,000 tons

② System expansion: Modular design, flexible capacity expansion by extending conveyors and adding screening modules

③ Process connection: Can be used as a primary crushing system, forming a large-scale production line with medium and fine crushing cone crushers and sand making machines

① Processing objects: Concrete blocks, waste bricks and tiles, demolition waste

② Recycling rate: Resource utilization rate can reach over 90%

③ Finished product applications: Recycled aggregates can be used for road base, brick making, low-grade concrete, etc.

④ Environmental protection features: Optional iron removers, light material separators, and dust collection systems for green production

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Your 10-40TPH Calcium Carbonate Plant Is Taking Off——Is Your Vertical Mill Ready for the Ethiopian Highland’s Challenge?

Can a Mobile Coal Crusher Really Survive Indonesia’s Rainy Season While Delivering 200 t/h?

Are You Losing Profits Due to Inefficient Rock Crushing? Discover How Henan Baichy’s Advanced Crushers Can Double Your Output and Meet EPA Standards!

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!