Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

• Grid type: There are two types: energy-saving type and conventional type. It is mostly used in one-stage grinding or coarse grinding and often forms a closed-circuit cycle with a spiral classifier.

• Overflow type: It is also divided into energy-saving type and conventional type. It is mostly used in two-stage grinding or fine grinding and often forms a closed-circuit grinding with a cyclone.

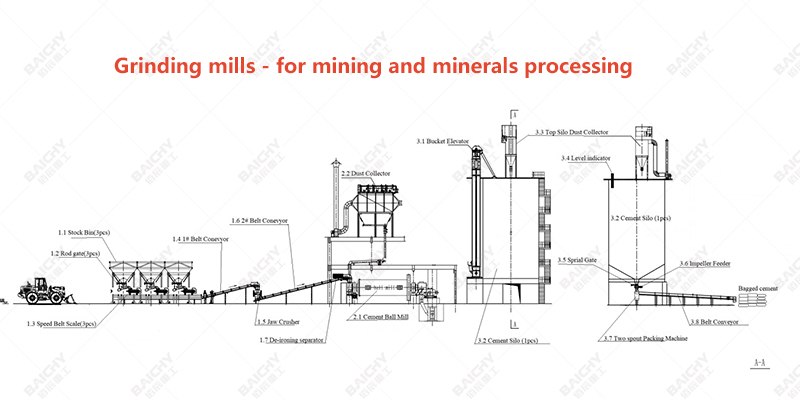

• The material enters the mill evenly through the feeding device and enters the first bin of the mill through the hollow shaft spiral of the feeding.

• There are stepped linings or corrugated linings in the first bin, which are filled with steel balls of various specifications. When the cylinder rotates, the steel balls have a heavy impact and grinding effect on the material.

• After the material reaches coarse grinding in the first bin, it enters the second bin through a single-layer partition plate. The bin is inlaid with a flat lining plate and steel balls to further grind the material.

• During the rotation of the cylinder, the grinding body also slides, giving the material a grinding effect.

Ball mill cylinder

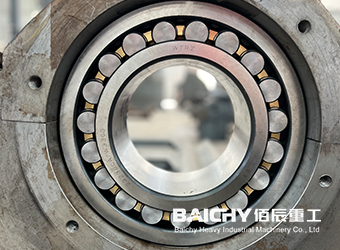

Ball mill bearing

Ball mill liner

Grinding medium steel balls

| Model | Ф1500×4500 |

|---|---|

| Cylinder Rotating Speed (r/min) | 27 |

| Ball weight(t) | 11 |

| Feeding Size(mm) | ≤25 |

| Discharging Size(mm) | 0.074-0.4 |

| Capacity(t/h) | 3-6 |

| Power(kw) | 110 |

• The ball mill liner is made of high-strength wear-resistant material, with high hardness, good toughness, impact resistance, wear resistance and other characteristics, ensuring the stability and durability of the equipment in harsh environments.

• The mining ball mill has a large processing capacity and can grind materials efficiently to meet the needs of large-scale industrial production.

• The ball mill effectively reduces energy consumption and improves grinding efficiency through optimized design and the use of advanced technologies, such as large double-row spherical roller bearings, grooved annular liner, etc., to achieve the purpose of energy saving and consumption reduction.

• The ball mill has strong adaptability to materials and can be used for dry grinding and wet grinding. It has a large crushing ratio and is easy to adjust the fineness of the powdered product to meet different production needs.

• The mining ball mill has a simple and strong structure, reliable operation, simple maintenance and management, and a high operating rate, which ensures the stability and reliability of the equipment.

• The ball mill adopts a closed system with strong sealing, which reduces the generation of dust, reduces pollution to the environment, and meets environmental protection requirements.

• The discharge port design is flexible, and iron removers and other equipment can be selected as needed, which improves the flexibility and applicability of the equipment.

• Reasonable feed port design increases the feed volume, improves the grinding fineness and processing volume, and thus increases the output.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.