Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

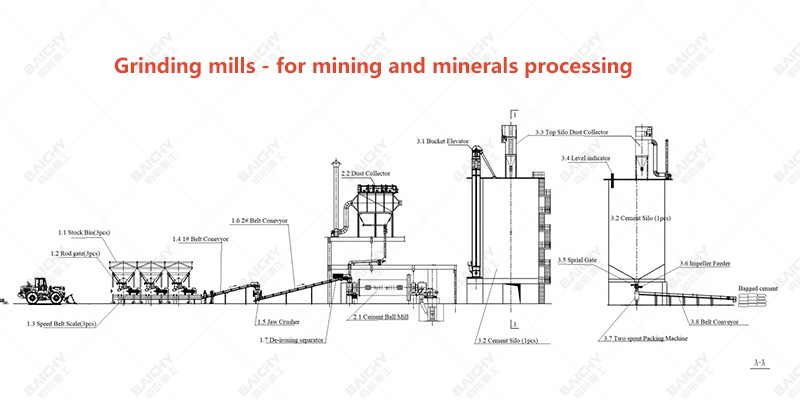

In industries like mining, building materials, and chemicals, ball mills are core grinding equipment, and their performance directly impacts production efficiency and finished product quality. The 1200x2400 ball mill, with its moderate dimensions and efficient grinding capacity, is an ideal choice for small and medium-sized production lines. This article provides an in-depth analysis of the model's structure, operating principle, performance advantages, and practical application scenarios, serving as a reference for your equipment selection.

The 1200x2400 ball mill is a horizontal grinding machine with a barrel diameter of 1.2 meters and a length of 2.4 meters. It primarily consists of a barrel, feed mechanism, drive system, liner, and grinding media:

• Barrel Design: Made of rolled and welded high-quality steel plates, it features an internal high-manganese steel liner for strong wear resistance and easy replacement.

• Drive System: Equipped with a motor, reducer, and gear transmission, it operates smoothly and consumes minimal energy. • Grinding Media: Available in various materials, including steel and ceramic balls, to meet diverse material grinding needs.

1. Operating Principle

Material enters the drum through the inlet. As the drum rotates, the grinding media impacts and grinds the material under centrifugal force, ultimately achieving the desired fineness and discharging it through the discharge port.

2. Core Advantages

• Efficient Grinding: The optimized drum aspect ratio extends material residence time and improves grinding efficiency.

• Energy Consumption Control: The scientifically designed transmission system achieves over 15% energy savings compared to traditional equipment.

• High Adaptability: Suitable for dry or wet processing of materials such as metal ores, non-metallic ores, and cement clinker.

Ball mill cylinder

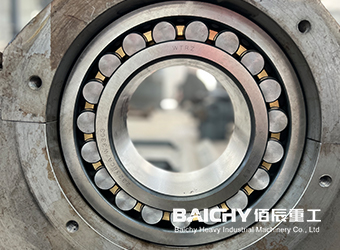

Ball mill bearings

Ball mill lining

Grinding media steel balls

| Model | Ф1200×2400 |

|---|---|

| Cylinder Rotating Speed (r/min) | 36 |

| Ball weight(t) | 3 |

| Feeding Size(mm) | ≤25 |

| Discharging Size(mm) | 0.075-0.6 |

| Capacity(t/h) | 1.5-4.8 |

| Power(kw) | 30 |

A1: The 1200x2400 ball mill is highly versatile. By adjusting the grinding media (such as ball size and ratio), material concentration, and grinding time, it can be used for both coarse and fine grinding. The shorter drum allows for higher efficiency in coarse grinding, while the appropriate length ensures a certain grinding fineness, making it ideal for full-process grinding operations in small and medium-sized mills.

A2: This is usually a sign that the machine needs to be shut down for inspection. Common causes include:

1. Grinding media wear: Steel balls are worn down or insufficiently added, resulting in reduced impact force and grinding efficiency. Regular replenishment of steel balls is necessary.

2. Liner wear: Excessive wear of the drum liner affects the efficiency of lifting the material.

3. Uneven feeding or blockage: The feed rate is too fast or too slow, or the feed/discharge port is clogged.

4. Changes in material properties: The material hardness or particle size changes, but the operating parameters are not adjusted in a timely manner.

A3: Yes, 1200x2400 ball mills are generally designed for both dry and wet grinding. The main differences between the two are:

1. Wet grinding: The material is mixed with water (or other liquid) to form a slurry for grinding. Its advantages are high efficiency and low dust production, making it the most commonly used method in metal beneficiation. The equipment structure must consider slurry inlet and outlet, as well as sealing.

2. Dry grinding: The material is ground in a dry state. This places high demands on the equipment's sealing and ventilation and dust removal systems.

When ordering, please clearly inform the manufacturer of your process requirements to ensure that the equipment design (such as the discharge method) meets your requirements.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.