Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

In the industrial trend of pursuing large-scale and green production, the performance of core grinding equipment directly determines a company's production capacity, costs, and market competitiveness. The SRM1500 vertical roller mill, a culmination of modern grinding technology, is becoming a strategic choice for many companies seeking to reduce costs and increase efficiency with its exceptional energy efficiency.

The SRM1500 is no ordinary grinding equipment; it's a solution designed to meet the challenges of demanding industrial production.

1. Outstanding Energy Efficiency

• Significantly Reduced Energy Consumption: Utilizing an advanced material bed grinding principle, it reduces overall power consumption by up to 30%-50% compared to traditional ball mills, significantly reducing operating costs.

• Powerful Processing Capacity: Designed for materials such as cement raw materials, slag, and pulverized coal, it boasts high throughput, easily meeting the demands of large-scale, continuous production.

2. Stable Operation and High Reliability

• Sturdy Structural Design: The main unit is robust, and the core grinding components are made of high-quality, wear-resistant materials, ensuring strong wear resistance and a long service life, effectively reducing downtime and maintenance.

• Intelligent Control System: Equipped with an advanced automated control system, it enables smooth start-up and shutdown, automatically adjusts the material layer thickness and grinding pressure, and ensures continuous operation at optimal conditions. It is easy to operate, safe, and reliable.

3. Outstanding Overall Benefits

• Excellent Product Quality: High grinding efficiency, uniform product particle size, and easy fineness adjustment meet the stringent powder quality requirements of various applications.

• Excellent Environmental Performance: The equipment operates quietly, and the system's overall sealing effectively reduces dust spillage, helping companies achieve clean production and meet environmental standards.

1. Highly Integrated and Compact: Integrating multiple processes into a single unit significantly simplifies the process and reduces construction and equipment investment costs.

2. Extremely High Efficiency and Low Energy Consumption: The "burden grinding" principle utilizes far more energy efficiently than the "impact friction" principle of traditional ball mills, which is the fundamental reason for its energy savings.

3. High Drying Capacity: By fully utilizing waste heat from exhaust gases, it can process raw materials with high moisture content, eliminating the need for pre-drying equipment.

4. Stable Product Quality: A built-in high-efficiency powder classifier enables flexible and precise control of product fineness, resulting in excellent particle size distribution.

5. Environmentally Friendly: The entire system operates under negative pressure, minimizing dust leakage. Combined with a high-efficiency dust collector, it enables clean production.

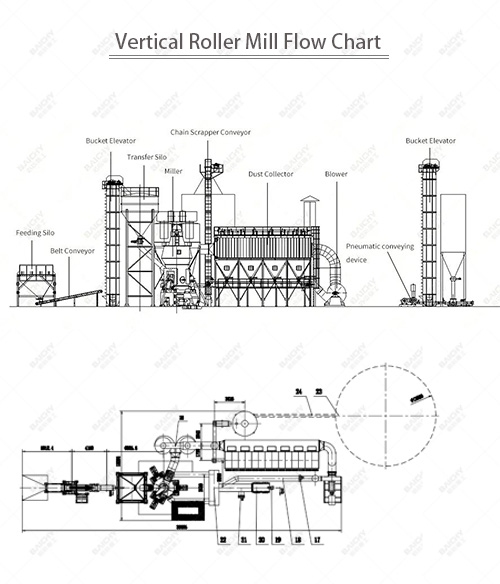

The SRM1500 vertical roller mill's process flow is a sophisticated, interconnected closed-loop system. Through the perfect combination of mechanical rolling and wind conveying and sorting, it achieves high efficiency, energy saving, environmental protection and intelligent control of grinding operations, and is an ideal choice for modern large-scale industrial grinding production.

| Model | SRM1500 |

|---|---|

| Grinding table dia.(mm) | 1500 |

| Max feeding size(mm) | ≤38 |

| Discharge size(um) | 212-45 |

| Discharge size(mesh) | 70-325 |

| Air-in tempreture(℃) | ≤350 |

| Air-out tempreture(℃) | 70-95 |

| Input material moisture | 4-15% |

| Final moisture | ≤1% |

| Capacity(t/h) | 13-48 |

| Motor Power(kw) | 250-355 |

A: Energy efficiency is one of the core advantages of a vertical roller mill. The SRM1500 utilizes the "burden grinding" principle, resulting in significantly higher energy efficiency than the "impact friction" principle of a ball mill. Specifically, it offers the following benefits:

Low power consumption: Overall system power consumption can be reduced by 30% to 50%, resulting in significant savings in long-term electricity bills.

Strong drying capacity: Kiln exhaust gas can be used to simultaneously dry and grind wet materials, eliminating the need for a separate drying system and further reducing energy consumption.

A: We prioritize the durability and maintainability of our equipment:

Long-life design: The grinding rollers and grinding disc liners are made of high-chromium alloy cast iron or other high-end wear-resistant materials and undergo an optimized heat treatment process, ensuring a long service life. This significantly reduces replacement frequency and spare part costs.

Easy maintenance: The modular design allows the grinding rollers to be folded out of the machine for easy inspection and maintenance. The hydraulic system automatically raises and lowers the rollers, reducing startup loads and daily operating effort.

A: The SRM1500 was designed with operational stability in mind.

Sturdy structure: The main machine base utilizes a sturdy cast structure, providing sufficient rigidity and effectively suppressing vibration.

Intelligent control: Automatically monitors and adjusts key parameters such as grinding pressure and material layer thickness to ensure a stable grinding process. When abnormal vibration is detected, the control system issues an alarm or initiates a protective shutdown to ensure equipment safety.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.