Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

C100 jaw crusher is a classic model, designed for coarse crushing in mines, crushing of sand and gravel aggregates, and other scenarios. With high processing capacity, durable structure, and low maintenance cost, C100 has become the preferred equipment for many mines, quarries, and construction waste recycling projects.

• Efficient crushing: Optimize the motion trajectory of the movable jaw to improve crushing efficiency.

• Sturdy and durable: High manganese steel jaw plate + welded steel frame, suitable for high-intensity operations.

• Intelligent adjustment: Hydraulic adjustment of the discharge port, easy operation.

• Widely applicable: Can handle high-hardness materials such as granite, basalt, and iron ore.

1. Coarse crushing in mines: Suitable for primary crushing of metal ores such as gold, iron, and copper, with large feed and strong processing capacity.

2. Aggregate production: crushing hard rocks such as granite and basalt to produce 0-200mm aggregate for construction and road construction.

3. Construction waste recycling: adapt to mobile crushing stations to crush concrete and bricks to achieve resource recycling.

| Model | C100 |

|---|---|

| Feeder Opening Size(mm) | 750x1060 |

| Max. Feeding Size(mm) | 600 |

| Outlet adjusting Range(mm) | 70-200 |

| Centrifugal Shaft Speed(rmp) | 260 |

| Motor Power(kw) | 132 |

| Capacity(t/h) | 150-300 |

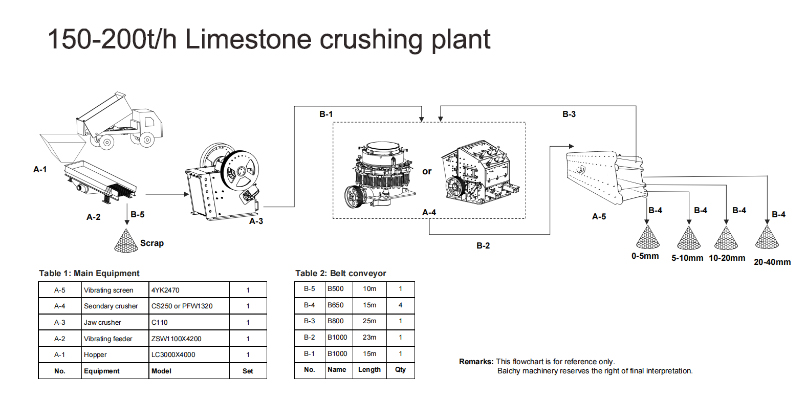

| Capacity | 150-200t/h |

|---|---|

| Feeder | ZSW1142 |

| Jaw Crusher | C100 |

| Impact Crusher | PFW1315 |

| Vibrating Screen | 4YK2160 |

| Belt | 7 Sets |

• The raw materials are first crushed by a C100 jaw crusher, and the crushed materials are conveyed to the PFW1315 impact crusher by conveyor for further crushing until the required particle size is reached.

• The crushed materials are conveyed to the 4YK2160 vibrating screen by conveyor for screening, and materials of different specifications are screened out to meet the needs of different customers.

• The whole production line is reasonably configured, and the connection between equipment is smooth, which can achieve efficient and stable crushing production.

• The selection of equipment such as the C100 jaw crusher, PFW1315 impact crusher, and 4YK2160 vibrating screen ensures the stability and efficiency of the production line.

• The equipment has superior performance and large processing capacity, which can meet the production needs of 150-200t/h.

• The production line configuration is flexible and can be adjusted and optimized according to actual production needs.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!