Rock crusher is a kind of mechanical equipment specially used for crushing various types of rocks, ores and building stones. It crushes large rocks into aggregates or sand particles of different specifications by extrusion, impact, grinding and other methods. It is widely used in mining, construction aggregate production, machine-made sand processing and engineering crushing. According to the crushing principle and discharge requirements, it is mainly divided into jaw crusher (coarse crushing), cone crusher (medium and fine crushing), impact crusher (particle shape optimization) and impact sand making machine (fine crushing and shaping). It has the characteristics of high efficiency and energy saving, high degree of automation and strong adaptability. It can handle various hardness rocks such as granite, basalt, limestone, etc., and meet the crushing needs of different industries.

Main types of rock crushing equipment

How to choose rock crushing equipment in 2024? This article explains the differences between jaw crusher (coarse crushing), cone crusher (medium and fine crushing), and impact crusher (particle shape optimization), and includes mobile crushing station quotes and hard rock crushing solutions such as granite/basalt. Click to get the technical manual!

1. Jaw crusher

• Working principle: Rock is crushed by periodic extrusion between the movable jaw and the fixed jaw, with a "V"-shaped cavity design.

• Features: Simple structure, large processing capacity, suitable for coarse crushing (feed size ≤1500mm, discharge 100-350mm).

• Application: Primary crushing in mines and quarries, hard rock with compressive strength ≤320MPa (such as granite and basalt).

2. Cone crusher

• Working principle: Multi-layer extrusion crushing is formed between the swing-type crushing cone and the fixed liner.

• Features: High crushing ratio, low energy consumption, suitable for medium and fine crushing (discharge ≤50mm), divided into spring, hydraulic, compound, etc.

• Application: Secondary and tertiary crushing of hard rocks (such as iron ore and quartzite).

3. Impact Crusher

• Working Principle: The high-speed rotor impacts the rock, and the impact plate is used to collide and crush it, and it also has the self-crushing of "stone hitting stone".

• Features: The finished product has good particle shape (many cubes), and the particle size of the output can be adjusted (such as 20-70mm).

• Application: Medium and fine crushing of medium and low hardness rocks (limestone, sandstone), and production of building aggregates.

4. Impact Crusher (Sand Making Machine)

• Working Principle: Centrifugal acceleration ejection of stones, through "stone hitting stone" or "stone hitting iron" to achieve fine crushing and shaping.

• Features: The output is fine (0-5mm sand grade), the powder content is controllable, and it is suitable for machine-made sand production.

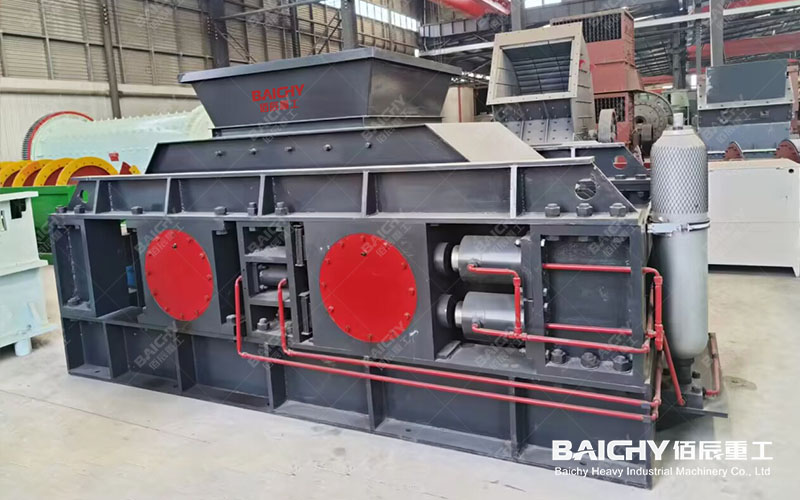

5. Roller Crusher

• Working Principle: Double rollers rotate in opposite directions to squeeze and crush, and the roller gap can be adjusted to control the output.

• Features: Less over-crushing, suitable for medium and fine crushing of medium and low hardness rocks (such as coal, clay, shale).

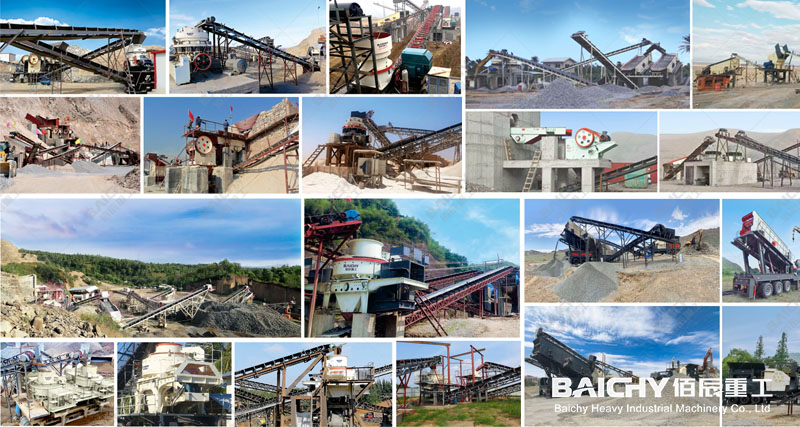

6. Mobile crushing station

• Features: Integrates feeding, crushing, and screening, tire or crawler drive, flexible transfer.

• Application: Construction waste treatment, temporary quarrying projects, and reducing material transportation costs.

Key factors for selection

1. Rock characteristics

• Hardness (Mohs hardness or compressive strength): A Cone crusher or jaw crusher is preferred for high-hardness rocks.

• Moisture content/viscosity: Viscous materials require anti-blocking design (such as increasing the feed inlet).

2. Capacity requirements

• Small production lines (50-100t/h) can choose a jaw crusher + impact crusher combination; large mines (500t/h+) require multi-stage cone crushers.

3. Finished product requirements

• Particle size distribution: Aggregate production requires multi-stage screening, and machine-made sand focuses on impact crushing and shaping.

• Particle shape standard: High-speed rail and airport projects have strict requirements on needle-like content.

4. Environmental protection and energy consumption

• Closed design reduces dust, and frequency conversion technology saves power consumption (such as the cone crusher intelligent control system).

FAQs

Q: Which equipment should I choose for crushing basalt?

A: We recommend the combination of "jaw crusher (primary) + cone crusher (secondary)". Basalt has high hardness and strong abrasiveness, and the wear-resistant lining of the cone crusher is more durable.

Q: How to choose between mobile and fixed types?

A: Mobile types are suitable for projects with short construction periods and scattered sites (such as highway construction), while fixed types are suitable for long-term ,large-scale production.