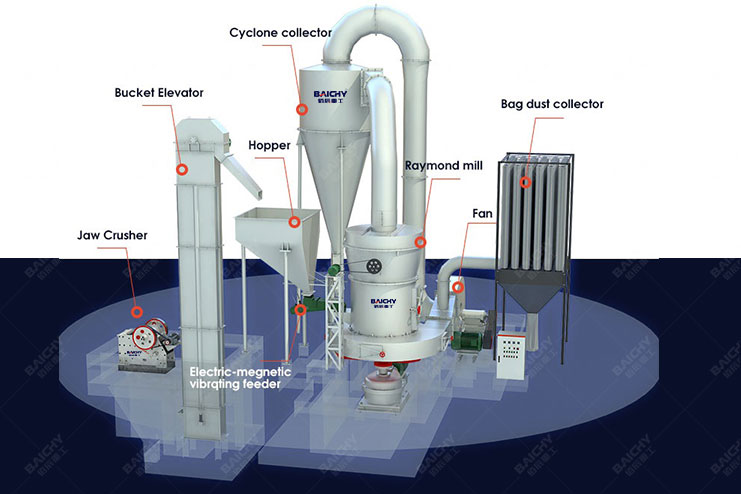

Operational process

Ⅰ. Boot sequence

Start the fan - start the host machine - start the classifier - start the bucket elevator - start the screw conveyor - start the pulse dust collector fan - start the air compressor - start the feeding belt conveyor - start the electromagnetic vibration feeder - start the bucket elevator Machine - start the hammer crusher - start the GZG vibrating feeder - start the packaging machine.

Ⅱ. Shutdown sequence

First stop the GZG vibrating feeder - stop the hammer crusher - stop the bucket elevator - stop the electromagnetic vibrating feeder - stop the belt conveyor - stop the main machine - stop the fan - stop the classifier - stop the dust collector fan and air compression Machine - stop screw conveyor - stop bucket elevator - stop packaging machine.

Ⅱ. Maintenance of various equipment.

Fan

Ⅰ. This machine is the main equipment in the entire production system. The entire production relies on it to generate air volume and air pressure, which blows up the finely ground materials in the mill. Through the blockage of the powder selector, qualified materials enter the powder collector, and unqualified particles fall down to continue grinding. The entire system It is an air circulation system, and there must be no air leakage in any part of the entire pipeline.

Ⅱ. When working, always check the lubricating oil and operating current in the fan bearing chamber. If the lubricating oil is missing, add it in time to 5-10mm above the red dot in the oil window. If the current can still exceed the rated current, the fan motor It is necessary to add high temperature resistant grease in time according to the maintenance rules of the motor.

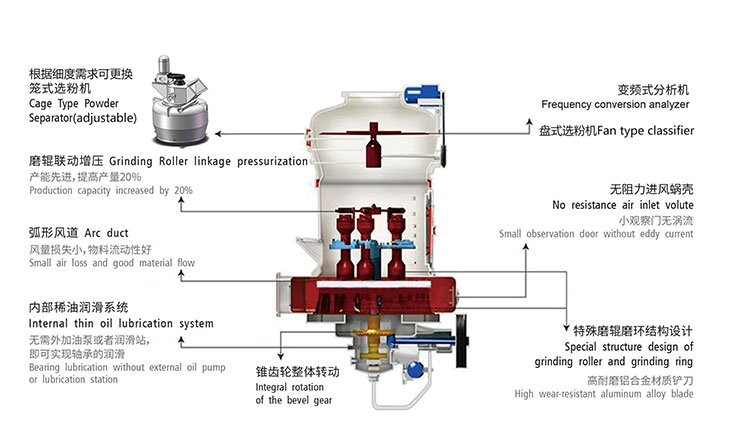

Host

Ⅰ. This machine is one of the main equipment in the entire production process. The entire production relies on the rotation and collision of the grinding roller and the grinding ring to grind the materials into powder.

Ⅱ. When working, listen to the sound of the grinder. If you find any abnormal noise, stop it immediately, check and troubleshoot. When working normally, the sound of the grinder is clear and crisp. If the sound is dull, the feeding amount should be reduced. After the sound is normal, slowly adjust the electromagnetic vibration feeder to increase the feeding amount to achieve the best state.

Ⅲ. Every 24 hours of work, open the grinding door and add grease to the four hanging roller bearing chambers and the central axis cylinder. Always check the thin oil lubrication part of the lower part to see if there is oil leakage or lack of oil. It is advisable to add lubricating oil in time to 5-10mm above the red dot of the oil sight window.

Classifier

Ⅰ. This machine is a device for product fineness in the production system. If the product has finer fineness, reduce the speed of the classifier; if the product has coarser fineness, increase the speed of the classifier. For product fineness of 200 mesh, the speed of the classifier is 450r/min.

Ⅱ. Always check the lubricating oil condition of the machine to see if there is any oil leakage. If there is any oil leakage, eliminate it in time. There are three pipes outside the body. The upper pipe is the exhaust pipe, the middle pipe is the refueling pipe, and the lower pipe is the lubricating oil level pipe. Always open the plug of the lower pipe to see if there is any lubricating oil overflowing. If the lubricating oil is not added in time, The bearing chamber between the pulley outside the machine body and the machine body needs to be lubricated every three days of operation.

Screw conveyor.

Ⅰ. It is a device that transports fine powder to a hopper elevator.

Ⅱ. Always check whether the lubricating oil of the reducer is lacking and add it in time. The 7.5kw screw conveyor and the middle hanger need to be lubricated three times per shift. The rear part of the machine needs to be lubricated every week.

Bucket elevator

Ⅰ. It is a device for lifting materials into the warehouse.

Ⅱ. After the new machine has been running for one shift, the nuts of each hopper must be tightened without leakage. Grease should be added to the upper and lower bearing chambers every working week, and the oil level of the reducer should be checked on the dipstick. If it is missing, add it in time.

Belt conveyor

Ⅰ. It is a transfer and transportation equipment for materials.

Ⅱ. Always check whether the conveyor belt is deviating or running out of material, and make timely adjustments if necessary. The bearing chambers at the nose and tail of the machine need to be lubricated every week.

Hammer Crusher or Jaw Crusher

Ⅰ. It is a device for breaking large pieces of materials into small pieces.

Ⅱ. Always observe the operation of the machine to see if there is vibration. If there is vibration, open the upper part of the machine body and check whether the hammer on the rotor is broken, causing the weightless rotor to run unbalanced and vibrate. Replace it in time. After using for a period of time, if the output decreases, replace the hammer head. The weight of the four symmetrical hammer heads should be the same to avoid causing machine operation and vibration. For the bearings on both sides, some grease should be added to each shift.

GZG vibrating feeder

Ⅰ. It is a device that quantitatively feeds large pieces of material to the hammer crusher. If the hammer crusher is stuck and the output is low due to feeding, the eccentricity of the two vibration motors should be adjusted to achieve the best state.

The motors in this production system are all carried out in accordance with the motor maintenance rules.