Multi-cylinder hydraulic cone crusher is an efficient crushing equipment that uses multiple hydraulic cylinders to achieve adjustment, overload protection, and cavity clearing functions. It is widely used in medium and fine crushing operations in mining, building materials, metallurgy, and other industries. Compared with a single-cylinder hydraulic cone crusher, it has more advantages in automatic control, crushing efficiency, and stability.

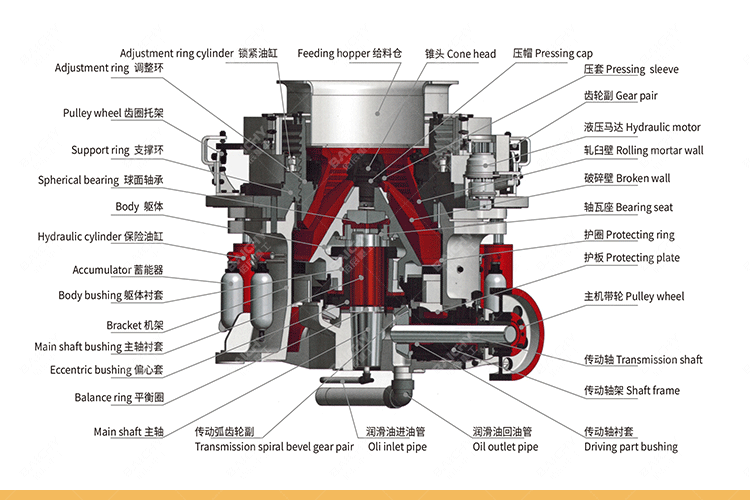

Main structural components of a multi-cylinder hydraulic cone crusher

• Crushing chamber: It consists of a movable cone (movable cone) and a fixed cone (fixed liner) to form a laminated crushing space.

• Hydraulic system: Multiple hydraulic cylinders (usually 3-6) are distributed around the machine to adjust the discharge port, overload protection, and cavity clearing.

• Spindle and eccentric sleeve: The motor drives the eccentric sleeve to rotate, driving the movable cone to do a swinging motion.

• Intelligent control system: Integrated sensors and PLC to achieve automatic adjustment and fault monitoring.

The core working principle of the multi-cylinder hydraulic cone crusher

1. Crushing process

• Swinging extrusion crushing: The motor drives the eccentric sleeve to rotate, so that the moving cone performs "a swinging motion", periodically approaches and moves away from the fixed cone, and squeezes, shears, and impacts the material.

• Lamination crushing: The material is subjected to force multiple times in the crushing chamber, and the particles squeeze each other, which improves the crushing efficiency and optimizes the finished particle shape (mostly cubic).

2. Hydraulic adjustment and protection

• Discharge port adjustment: The moving cone is raised and lowered synchronously by multiple hydraulic cylinders to accurately control the size of the discharge port to meet the requirements of different discharge particle sizes.

• Overload protection: When unbreakable objects (such as iron blocks) enter, the hydraulic system automatically releases pressure, the moving cone descends to discharge foreign objects, and then automatically resets to avoid equipment damage.

• One-button cavity clearing: The hydraulic system can quickly lower the moving cone, clear blocked materials, and reduce downtime.

Technical features of a multi-cylinder hydraulic cone crusher

• High efficiency and energy saving: laminated crushing technology increases production and reduces energy consumption.

• Intelligent control: PLC+sensor monitors the operating status in real time and automatically adjusts the discharge port and hydraulic pressure.

• Stable and reliable: A multi-cylinder hydraulic system is more stable than a single-cylinder system, reducing vibration and wear.

• Convenient maintenance: Hydraulic cavity cleaning and automatic protection functions reduce manual intervention and increase equipment life.

Application areas of the cone crusher

• Mining industry: medium and fine crushing of medium and high hardness ores such as iron ore, gold ore, copper ore, etc.

• Sand and gravel aggregate: crushing of high-hardness rocks such as granite, basalt, and river pebbles.

• Building materials industry: fine crushing of cement clinker, quartz sand, limestone, and other materials.

Comparison with a single-cylinder hydraulic cone crusher

| Comparison items | Multi-cylinder hydraulic cone crusher | Single-cylinder hydraulic cone crusher |

| Number of hydraulic cylinders | Multiple (3-6) | Single |

| Adjustment accuracy | Higher, synchronous control | Relatively low |

| Stability | Better, less vibration | Slightly worse |

| Automation degree | Higher, intelligent control | Relatively basic |

| Applicable working conditions | Medium and high hardness materials, fine crushing |

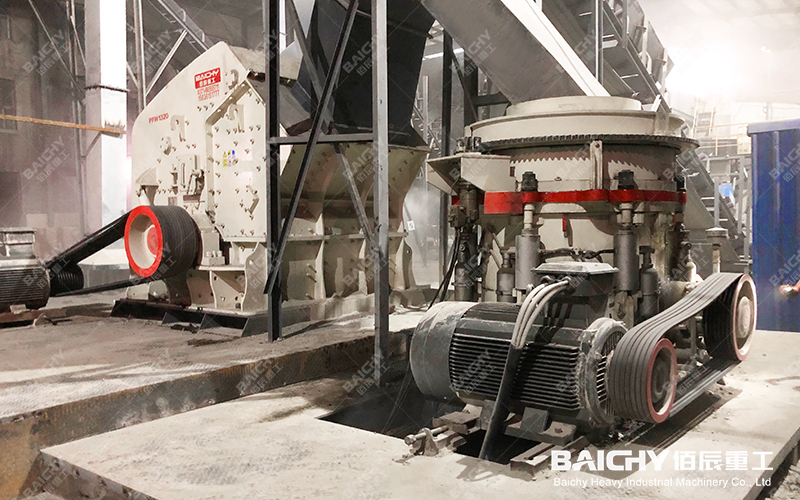

Multi-cylinder hydraulic cone crusher has become the core equipment in modern crushing production lines with its intelligent control, efficient laminated crushing, and stable operation characteristics, especially suitable for the fine crushing needs of high hardness materials.