SAG Mill vs Ball Mill: Core Differences, Working Principles and Application Scenarios

In the process of ore processing and beneficiation, SAG Mill and Ball Mill are two common grinding equipment, but they have significant differences in working principles, energy consumption, and applicable ore types. This article will compare the core differences between the two equipment in detail to help users choose a more efficient grinding solution based on actual needs.

Differences in working principles

1. SAG Mill

• Autogenous grinding + a small amount of steel balls assisted: mainly relying on the ore itself as the grinding medium, while adding a small amount of steel balls (usually accounting for 8%-15% of the mill volume) to assist in crushing.

• Direct feeding of large ore: can handle larger ore (usually ≤250mm) and reduce the primary crushing link.

• Impact + grinding combination: the ore falls freely in the cylinder to produce impact crushing, and the steel balls assist in fine grinding.

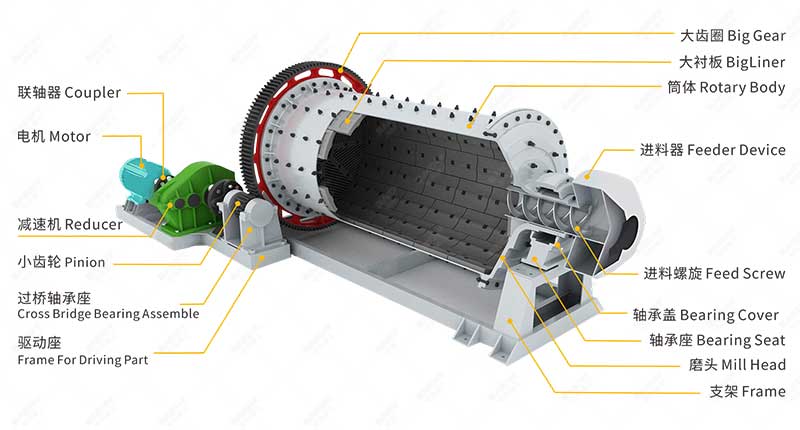

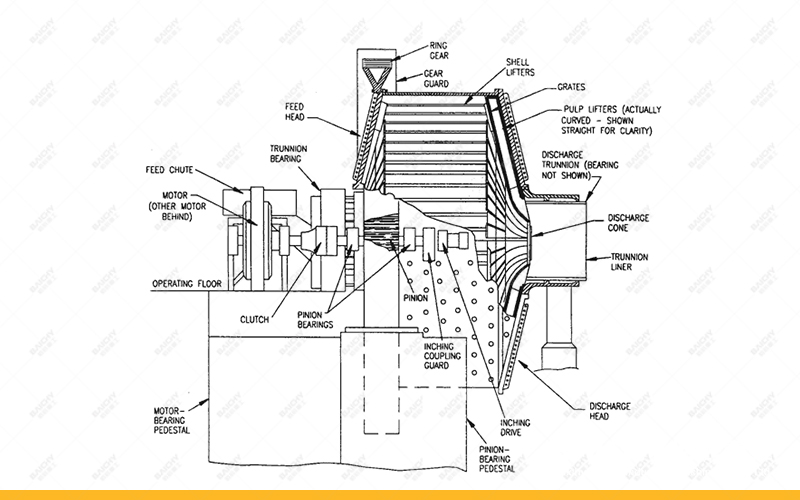

2. Ball Mill

• Relying on steel balls for grinding: completely relying on steel balls (accounting for 25%-45% of the mill volume) as grinding media, fine grinding is achieved through rolling and sliding friction.

• Requires pre-crushed ore: the feed particle size is small (usually ≤25mm), and supporting crushing equipment is required.

• Pure grinding action: suitable for fine grinding, but weak processing capacity for large ore.

Key differences:

| Characteristics | SAG Mill | Ball Mill |

| Grinding media | Ore + a small amount of steel balls | Pure steel balls |

| Feed size | ≤250mm | ≤25mm |

| Crushing method | Impact + grinding |

Pure grinding |

Energy consumption and efficiency comparison

1. Energy consumption

• SAG Mill: The unit energy consumption is high (about 10-15 kWh/t), but the overall process energy consumption may be lower due to the reduction of crushing links.

• Ball Mill: The unit energy consumption is low (about 5-10 kWh/t), but it needs to be equipped with a crushing system, and the comprehensive energy consumption may be higher.

2. Processing capacity

• SAG Mill: The single machine processing capacity is large (up to 5000t/d), suitable for large-scale mines.

• Ball Mill: The processing capacity is small, but the grinding accuracy is high, suitable for fine processing.

Applicable scenarios:

• Semi-autogenous mill: Medium-hard ores such as gold and copper are suitable for the "coarse grinding + fine grinding" combined process.

• Ball mill: Occasions where fine grinding is required, such as iron ore and bauxite.

Summary of advantages and disadvantages

Advantages of semi-autogenous mill

✔ Reduce the crushing link and reduce the complexity of the process.

✔ Adapt to large pieces of ore and save initial investment.

✔ Suitable for high-volume projects.

Advantages of ball mill

✔ Fineer grinding particle size (up to -200 mesh, accounting for more than 90%).

✔ Relatively low energy consumption, suitable for fine processing.

✔ Mature technology and low maintenance cost.

How to choose?

• Ore characteristics: high hardness and large particle size → Semi-autogenous mill is preferred; ultra-fine grinding is required → ball mill is selected.

• Production scale: Large-scale ore dressing plant → SAG mill + ball mill; small and medium-sized → single ball mill.

• Investment budget: SAG mill has high initial cost but simplified process, while ball mill has low supporting cost but requires a crushing system.

SAG mill and ball mill have their own focuses. SAG mill is suitable for coarse grinding and large-scale production, while ball mill is more suitable for fine grinding. The actual selection needs to be comprehensively evaluated in combination with ore properties, production needs and costs.