Comprehensive Analysis of the Applications of Impact Crushers

In the fields of mining crushing, construction aggregates, and industrial powder processing, selecting the right crushing equipment is crucial to determining production efficiency, product quality, and operating costs. With the surge in market demand for high-quality manufactured sand and high-specification aggregates, and the popularization of the energy-saving concept of more crushing, less grinding, impact crushers have evolved from an alternative option to a key, even preferred, piece of equipment in many process flows. Their unique stone-on-stone and stone-on-metal crushing principles give them unparalleled advantages in processing materials of medium hardness and below.

| Key Words | Comprehensive Analysis of the Applications of Impact Crushers |

|---|---|

| Product Model | Impact Crusher |

| Feed Size | ≤400mm |

| Motor Power | 45-315kw |

| Capacity | 10-400 t/h |

| Core Advantages | High efficiency and energy saving, excellent particle shape, flexible adjustment, and simultaneous shaping capabilities. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

What is an Impact Crusher?

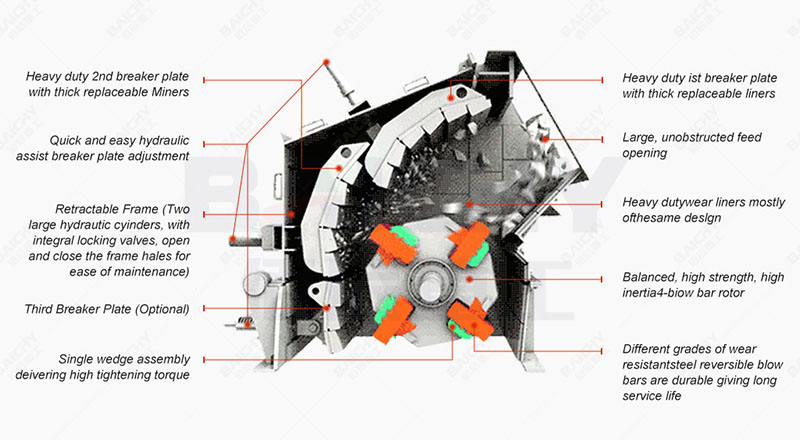

An impact crusher, also known as an impact breaker or sand making machine, is a highly efficient device that uses a high-speed rotating rotor to accelerate and propel materials, causing them to collide violently with impact plates (anvils) or with each other, thus achieving crushing. Its core working principle is kinetic energy crushing; after the material gains extremely high speed, the crushing mainly occurs along the internal crystal cleavage planes, resulting in excellent particle shape.

PF Impact Crusher Structure Diagram

Core Advantages and Wide Applications of Impact Crushers

Thanks to its unique principle, the impact crusher excels in several fields, with the following specific uses and advantages:

1. High-Performance Manufactured Sand Production (Core Application)

This is the most well-known application of impact crushers. The manufactured sand produced has a multi-faceted cubic particle shape, continuously adjustable gradation, and stable fineness modulus, effectively improving the workability, compactness, and strength of concrete. It fully meets the national GB/T 14684 Sand for Construction standard and is an ideal substitute for natural sand.

2. High-Quality Aggregate Shaping

Used after primary crushing equipment such as cone crushers or jaw crushers, it reprocesses the initially crushed aggregates. It effectively removes flaky and elongated particles, making the crushed stone (such as 5-10mm, 10-20mm specifications) more rounded and uniform, greatly improving the bulk density and market value of the aggregates. It is widely used in high-grade highways, railways, and airport runways where stringent aggregate requirements exist.

3. Medium and Fine Crushing Operations

For materials of medium and lower hardness, such as limestone, dolomite, weathered sand, and construction waste, impact crushers can be directly used as secondary or tertiary crushing equipment, achieving single-stage crushing, simplifying the process flow, and reducing investment costs.

4. Industrial Pulverization and Pre-treatment for Mineral Processing

In the deep processing of certain non-metallic minerals (such as calcium carbonate, quartz, and feldspar), impact crushers can be used for primary fine crushing and shaping, providing feed with uniform particle shape and sufficient cleavage for subsequent grinding or sorting processes, improving mill efficiency and sorting accuracy.

5. Resource Utilization of Construction Waste

Its stone-on-stone self-impact working method effectively reduces metal wear on wear parts when crushing construction waste (concrete blocks, bricks, and tiles), and effectively separates the reinforcing steel. It is a star equipment for the production of recycled aggregates from construction waste.

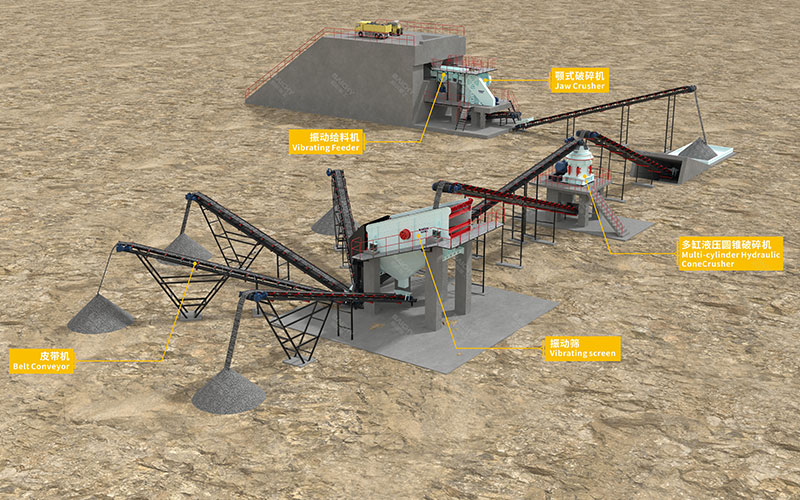

Impact crushing production line

Customer Case Study: Our 20 Years of Experience

Case: A large-scale green building materials base project in East China

Customer Requirements: Annual production of 3 million tons of high-quality manufactured sand and premium aggregates, requiring excellent product particle shape, grading conforming to the national standard for medium sand in Zone 2, and an environmentally friendly and intelligent production line.

Our Solution: We adopted a core process flow of jaw crusher (coarse crushing) + single-cylinder cone crusher (medium crushing) + two of our high-performance vertical shaft impact crushers (sand making and shaping). The impact crusher uses a convertible stone-on-stone and stone-on-iron design, which can be flexibly adjusted according to material characteristics.

Results: The manufactured sand produced has a rounded particle shape, a fineness modulus controlled between 2.6-2.9, and controllable stone powder content, fully meeting the requirements for C30-C60 concrete sand. The aggregate product has a needle-like and flaky content of less than 5%, becoming the designated material for key local projects.

Equipment Selection Recommendation

When selecting an impact crusher, the following factors should be considered. We can provide you with professional consultation:

• Material characteristics: hardness, moisture content, clay content, and feed particle size.

• Production capacity requirements: target hourly output.

• Product Requirements: Requirements for the fineness modulus and stone powder content of the finished sand; aggregate particle shape standards.

• Process Layout: Whether it is used as a sand-making main machine or a shaping machine determines its model and configuration (e.g., whether it is equipped with an air duct, dual motors, etc.).

We recommend providing material samples for small-scale testing before purchasing to obtain the most accurate equipment selection and parameter configuration.

Frequently Asked Questions (FAQ)

Q1: What are the differences between impact crushers and cone crushers? Where are they mainly used?

A1: Cone crushers use layered crushing and are more suitable for crushing high-hardness materials (such as granite and river pebbles), excelling in producing coarse aggregates. Impact crushers use kinetic energy for crushing, excelling in producing high-quality manufactured sand and shaping aggregates. They have significant advantages in particle shape control and are more suitable for materials with medium hardness or lower, or scenarios requiring high demands on the finished product shape.

Q2: Are the wear parts of impact crushers expensive to replace, and are the operating costs high?

A2: This is a common misconception. Modern impact crushers use a deep-cavity rotor design, high-quality alloy wear blocks (such as high-chromium cast iron), and modular installation methods, significantly extending the life of wear parts and reducing the crushing cost per ton of material. When crushing less abrasive materials, their overall operating costs are competitive.

Q3: Will the impact crusher produce excessive stone powder? How to control it?

A3: Our equipment is usually equipped with efficient powder selection or grading adjustment devices, such as adjustable-speed vibrating screens and air ducts. By adjusting parameters such as rotor speed, feed rate, and crushing chamber airflow, the stone powder content can be effectively controlled within the ideal range (e.g., between 10% and 15%), meeting different engineering needs.

Q4: Does the equipment support intelligent control and remote monitoring?

A4: Yes. As a manufacturer with 20 years of experience, our new generation of impact crushers can be seamlessly integrated into intelligent mining systems, providing IoT-based remote monitoring, fault warning, wear part life management, and automated feeding control, helping customers achieve intelligent and unmanned operations.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.