Simply put, a secondary crusher is a device that performs both secondary and tertiary crushing in a stone production line. Its task is to further break down the large lumps of stone (typically around 200-300mm in diameter) produced after primary (coarse) crushing into smaller, finished aggregates that meet specifications (e.g., 5-10mm, 10-20mm, 20-31.5mm, etc.).

To better understand, let's look at the typical quarry crushing process:

1. Primary Crushing (Coarse Crushing):

◦ Equipment: Typically a jaw crusher.

◦ Task: Crushes the large ore (potentially over 1 meter in diameter) from the blasting face into smaller lumps of approximately 200-300mm in diameter. This is the first stage of the production line.

2. Secondary Crushing (Secondary and Tertiary Crushing):

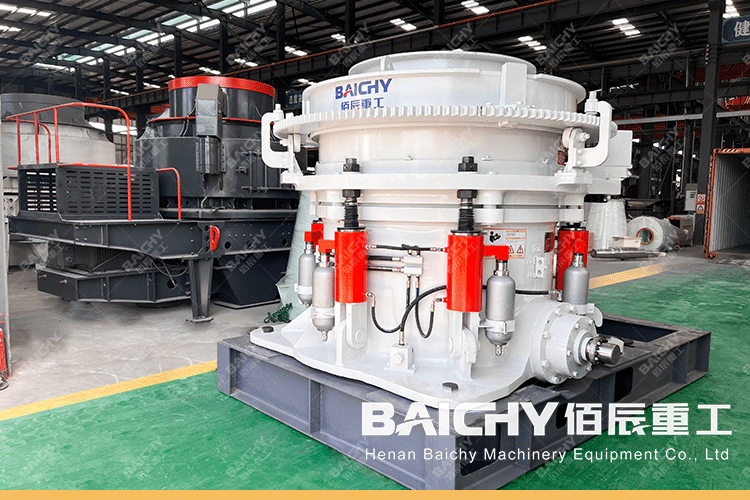

◦ Equipment: This is the focus of our discussion, including equipment such as cone crushers and impact crushers.

◦ Task: Receives material from the primary crusher and crushes it to a smaller size (e.g., less than 30-50 mm) in preparation for subsequent screening and sand making.

3. Tertiary Crushing (Fine Crushing/Sand Making):

◦ Equipment: Typically a sand making machine (vertical shaft impact crusher).

◦ Task: Specializes in producing manufactured sand with a size of 0-5 mm.

Thus, the secondary crusher is the "heart" of the entire aggregate production system. Its performance and efficiency directly determine the yield, particle shape, and cost of the final product.

How does a quarry choose secondary crushing equipment?

Selecting secondary crushing equipment is a comprehensive decision that requires consideration of many factors. The following are the most critical considerations for quarry owners and engineers:

1. Raw material properties (this is the primary determining factor)

• Hardness and abrasiveness: This is the most critical factor.

◦ Highly hard and abrasive rocks (such as granite, basalt, and river pebbles): A cone crusher is essential. Because cone crushers use a laminated crushing principle, their wear-resistant parts are more durable. While the equipment investment is high, operating costs (wear and tear of wearing parts) are low, and their stability is excellent.

◦ For medium-to-low hardness, low-abrasive rocks (such as limestone, dolomite, and marble): An impact crusher can be used. Impact crushers use the impact crushing principle, resulting in fine-grained finished products and a low price, but their wearing parts wear rapidly, making them unsuitable for crushing very hard materials.

• Feed size and discharge requirements: Select a secondary crusher with different chamber types and specifications based on the primary crusher's output size and the desired final product specifications.

• Moisture and clay content: If the material is sticky or has a high moisture content, it can easily clog the crushing chamber. In this case, a cone crusher is generally more resilient than an impact crusher.

2. Capacity requirements

• Determine the required tons of output per hour based on the quarry's production scale and market demand. Different cone and impact crusher models have different capacity ranges, which need to be matched.

3. Finished Product Shape Requirements

• High-standard particle shape requirements (for high-grade concrete and asphalt aggregate): Impact crushers produce finer-quality stone particles, often cubic, with sharp edges and corners and good adhesion.

• General particle shape requirements: Cone crushers produce a slightly higher content of flakes in their finished products, but through multi-layer screening and recirculating crushing, they can still meet the requirements of most civil construction aggregates. Modern high-performance cone crushers have also achieved excellent results in improving particle shape.

4. Investment and Operating Costs

• Initial investment: For the same production capacity, the purchase price of a cone crusher is generally higher than that of an impact crusher.

• Operating costs:

◦ Wear and tear of wearing parts: When crushing hard rock, the hammers of an impact crusher wear very quickly, requiring frequent replacement and high cost. The mortar and crushing wall of a cone crusher are more wear-resistant and have a much longer lifespan.

◦ Energy consumption: Cone crushers generally consume more energy than impact crushers.

5. Environmental requirements

• Modern quarries have strict regulations on dust and noise. Both types of equipment require dust removal equipment. Impact crushers typically generate more dust during the crushing process, requiring a more efficient dust removal system.

Comparison of Mainstream Secondary Crushing Equipment

| Features | Cone Crusher | Impact Crusher |

| Applicable Materials | High-hardness, highly abrasive rocks (granite, basalt, etc.) | Medium-low-hardness rocks (limestone, coal gangue, etc.) |

| Crushing Principle | Laminated Crushing | Impact Crushing |

| Finished Particle Shape | Average, slightly more needle-shaped | Excellent, cubic, good particle shape |

| Equipment Investment | High | Low |

| Operating Cost | Low (wear-resistant wearing parts, but high energy consumption) | High (fast wearing parts, but low energy consumption) |

| Maintenance Complexity | Relatively complex, requires specialized technicians | Relatively simple, easy blow bar replacement |

| Intelligence | High, often equipped with an automatic control system | Relatively low |

| Environmental Performance | Relatively good, relatively low dust generation | Relatively poor, requires strong dust removal |

Summary and Selection Recommendations

• If you are mining hard rock such as granite or basalt:

◦ Preferred option: Multi-cylinder hydraulic cone crusher. This is the mainstream and optimal choice for hard rock crushing, achieving the best balance between efficiency, wear resistance, and stability. • If you are mining medium-hard or lower rock, such as limestone:

◦ Option 1 (Focus on output and particle shape): Choose an impact crusher to obtain aggregate with better particle shape and a higher price.

◦ Option 2 (Focus on stability and low maintenance): If particle shape requirements are not extremely stringent, a cone crusher can also be selected for more stable operation and less downtime.

• Large, complex quarries:

◦ Depending on the rock properties and market positioning, a classic combination of "jaw crusher + cone crusher + sand making machine" or "jaw crusher + impact crusher + sand making machine" may be adopted.

The final choice is a balancing act that requires a comprehensive evaluation of rock properties, production capacity requirements, finished product specifications, budget constraints, and long-term operating costs. It is best to conduct actual material testing before making a decision.