Pyrophyllite

Pyrophyllite is a kind of clay mineral with a fine texture and low hardness (1-2). The newly developed pyrophyllite mine has a storage capacity of 2 million tons, of which the aluminum content is 30%-39%, and Fe2O3+TI2O 0.2%, suitable for blanks (molds) for synthetic diamonds, ceramics, refractory materials, glass fibers, carving stones, etc. It can be widely used in ceramics, metallurgy, building materials, the chemical industry, the light industry, and other industrial sectors.

| Fineness | Application Scenario | recommended equipment |

| Within 300 mesh | It is also used in ceramics and paper making, as well as fillers and carriers for rubber products, cosmetics, pesticides, etc. The new use of pyrophyllite is as a coating, and it is also a good raw material for making siding, and it can also be used to make white cement. | MTW Grinding Mill/vertical roller mill |

| 3mm | Refractory materials, refractory bricks |

Pyrophyllite Processing Technology

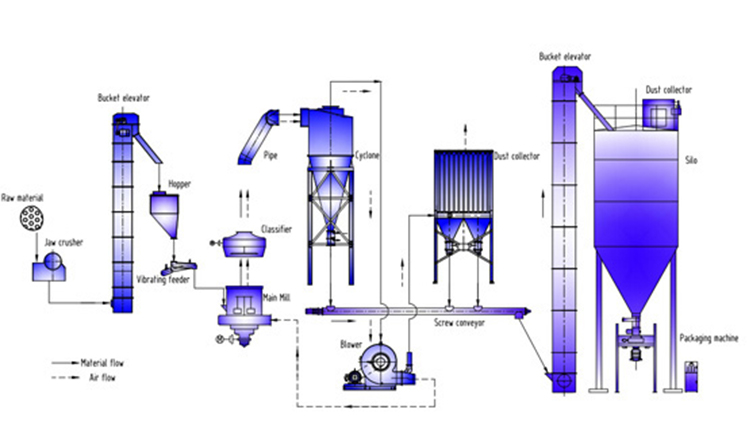

1. Crushing stage: large pieces of material are crushed by the crusher to the feed fineness that can enter the mill (15mm-50mm)

2. Milling stage: The small pieces of materials that meet the grinding conditions are uniformly and quantitatively entered into the grinding chamber of the mill through the conveying and feeding system, and are ground into powder in the grinding chamber.

3. Classification stage: The ground materials are classified through the powder classifier with the system airflow, and the unqualified powder is classified by the classifier and returned to the main mill for re-grinding.

4. Powder collection stage: the fine powder enters the powder collection system with the airflow through the pipeline, the air and powder are separated, and the finished powder is sent to the finished product silo by the conveying device, and then uniformly packed with a powder tanker or an automatic packing machine.

Recommended machines for Pyrophyllite grinding mill

According to different uses and different discharge fineness, the choice of Pyrophyllite mill will also be different.