Granite, as a high-hardness rock, is an important aggregate raw material for construction, highways, railways, and other fields. Faced with the increasing demand for sand and gravel aggregates from large-scale engineering projects, a stable, energy-efficient, and high-capacity crushing production line has become crucial.

This article will focus on a 300-ton/hour granite crushing production line, providing a one-stop solution from equipment selection and process flow to capacity optimization.

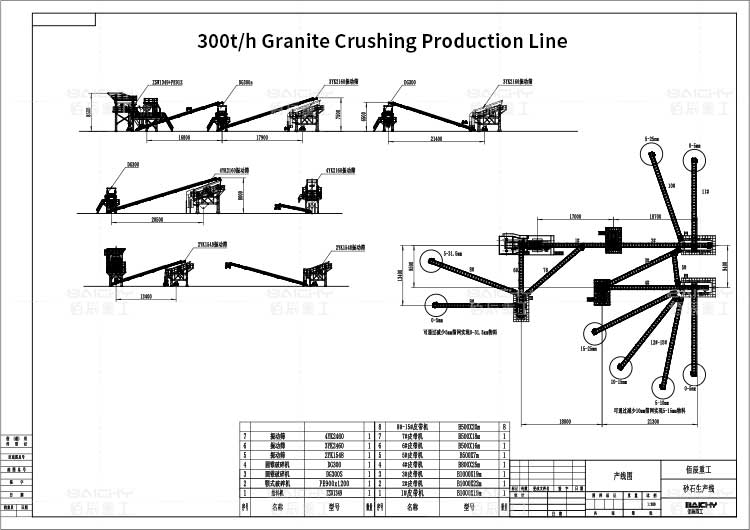

I. Core Equipment Configuration of the Production Line

Given the high hardness and abrasiveness of granite, the equipment must balance crushing force, wear resistance, and stability. The recommended configuration is as follows:

1. Coarse Crushing Stage – Jaw Crusher

• Use a large, deep-cavity jaw crusher with a feed size ≤1000mm and an output adjustment range of 150-300mm to ensure primary crushing efficiency.

2. Medium Crushing Stage – Cone Crusher

• Use a hydraulic cone crusher (such as a single-cylinder or multi-cylinder model) to process medium-sized granite, with an output size ≤70mm and a long service life for wear parts.

3. Fine Crushing and Shaping – Impact Crusher

• Fine crushing and particle shape optimization are achieved through a vertical shaft impact crusher, producing high-quality aggregates of 5-20mm with a cubic content ≥90%.

4. Auxiliary Equipment

• Vibrating feeder (for uniform feeding), circular vibrating screen (for multi-stage screening), belt conveyor system, dust removal and noise reduction device, etc.

II. Process Flow Design

1. Feeding and Coarse Crushing

Raw granite ore is fed into a jaw crusher via a vibrating feeder. After preliminary crushing, it is conveyed to a transfer stockpile by a belt conveyor.

2. Medium Crushing and Screening

The medium-crushed material is classified by a circular vibrating screen. Material >70mm is returned to the cone crusher for further crushing, while qualified material enters the fine crushing stage.

3. Fine Crushing and Shaping

The impact crusher shapes the aggregates, increasing product added value. The aggregates are then screened to produce sizes such as 0-5mm, 5-10mm, and 10-20mm. 4. Environmental Protection and Automation

The entire process is enclosed, equipped with a pulse dust collector and spray system, and uses PLC centralized control to reduce manual intervention.

III. Production Line Advantages and Highlights

• High and Stable Output: Redundant equipment design, single-line capacity can reach 300-320 tons/hour, with an operating rate ≥90%.

• Excellent Particle Shape: Multi-stage crushing + impact shaping, the aggregate needle-like and flaky rate is less than 8%, meeting high-standard material requirements.

• Energy Saving and Consumption Reduction: Cone crusher layer crushing reduces power consumption, and the impact crusher optimizes the transmission structure, saving more than 15% energy compared to similar products.

• Long-Term Economic Efficiency: Wear-resistant parts use high-manganese steel/alloy composite materials, extending the replacement cycle by 30% and reducing maintenance costs.

IV. Applicable Scenarios and Case References

This production line is suitable for:

• Large-scale aggregate production in large mines and quarries;

• Key engineering supporting sand and gravel bases (such as high-speed rail and highway construction);

• Regional building materials industrial parks with strict environmental protection requirements. Case Study: A granite crushing project in East China, after adopting this solution, achieved a daily output exceeding 7,000 tons, with the finished aggregate compressive strength ≥150MPa, far exceeding industry standards.

The success of the 300-ton/hour granite crushing production line relies on scientific equipment matching and process design. Through proper early planning, users can find the optimal balance between capacity, quality, and cost. For customized solutions or equipment selection support, please contact our professional team for detailed technical support!