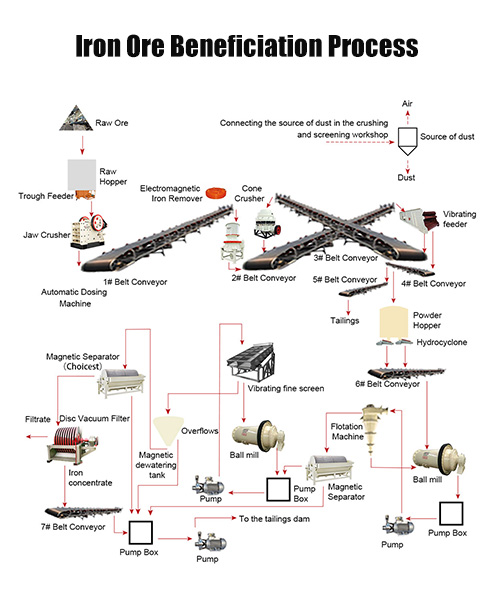

The advantages of iron ore process production lines are reflected in their technical integration, resource utilization efficiency, and sustainability. Especially in the context of the current global mining green transformation and intelligent upgrading, advanced process production lines have become the core focus of enterprises to enhance their competitiveness.

1. Technical integration advantage: full process optimization

Modular design

Through modular assembly (such as crushing, grinding, sorting, and dehydration modules), it can quickly adapt to different ore body characteristics (such as mixed hematite and magnetite).

Multi-technical synergy

Integrate dry pre-selection, wet re-selection, flotation, and other processes to achieve efficient sorting of complex ores.

2. Resource utilization advantage

Economically low-grade ore

Advantages: Bioleaching, microwave activation, and other technologies release the value of traditional abandoned mines.

Case: China Anshan Iron and Steel Qidashan Ore Dressing Plant uses microwave pretreatment technology to increase the recovery rate of extremely poor hematite with Fe 30% from 48% to 65%, extending the mine life by 15 years.

Tailings resource utilization

Advantages: Tailings reselection + building material utilization to achieve "zero waste".

Data: Brazil's Vale tailings reselection line recycles more than 2 million tons of iron-containing tailings each year, and processes siliceous tailings into environmentally friendly bricks, with additional income of $80 million per year.

Keywords: Iron ore concentrator case | Low-grade iron ore development | Magnetic separation process | Zero discharge of ore dressing wastewater | Tailings resource utilization | Intelligent concentrator | Mine environmental protection measures | Iron ore project investment return