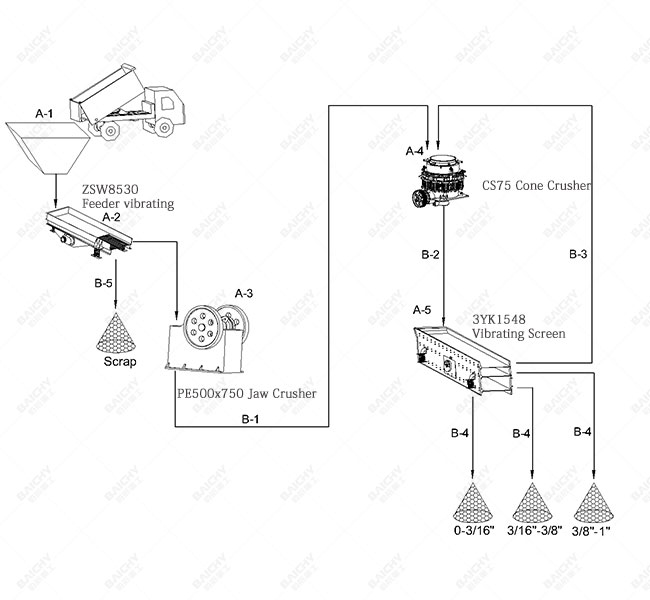

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW850X3000 | 1 |

| A-3 | Jaw Crusher | PE500X750 | 1 |

| A-4 | Cone Crusher | CS75 | 1 |

| A-5 | Vibrating Screen | 3YK1548 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B650 | 18m | 1 |

| B-2 | B650 | 23m | 1 |

| B-3 | B500 | 25m | 1 |

| B-4 | B500 | 16m | 3 |

| B-5 | B500 | 10m | 1 |

We offer a complete solution that provides a stable output of 50-80 tons of high-quality aggregates per hour, creating lasting value for medium-sized quarries with industry-leading return on investment. This article will provide an in-depth analysis of the entire process, from equipment selection to production optimization, helping you establish an efficient and stable aggregate production line.

Core Value: The perfect combination of stability, efficiency, and rapid return on investment

• Stable Output: Continuous production capacity of 50-80 tons/hour

• Excellent Quality: High-quality aggregates meeting stringent standards

• Rapid Return: Investment payback period can be shortened to 12-15 months

• Cost Optimization: Significantly reduced production and operating costs

In the sand and gravel aggregate production industry, a medium-sized production line with a capacity of 50-80 tons/hour is the ideal choice for many small and medium-sized quarries and construction aggregate processing enterprises:

• Moderate Investment: Balanced equipment investment and site requirements, controllable initial investment

• Market Matching: Meets the aggregate needs of regional infrastructure, commercial concrete plants, and small-scale engineering projects

• Flexible Adaptation: Production specifications can be flexibly adjusted according to market changes, reducing operating risks

• Reasonable Return: Annual production capacity of 120,000-150,000 tons, with a return on investment period controllable within 12-18 months

• Upgrade Potential: Reserved interfaces for future expansion, protecting long-term investment

Classic three-stage configuration: "Jaw Crusher + Cone Crusher + Vibrating Screen"

A mature solution verified by hundreds of successful projects

Core Advantages:

• Robust and durable, capable of processing high-hardness rocks (granite, basalt, etc.)

• Large feed opening design, reducing the workload of secondary blasting

• Simple structure, easy maintenance, reducing long-term operating costs

• Creates ideal feeding conditions for subsequent crushing

Core Technology:

• Laminated crushing principle, excellent finished product particle shape, needle-like and flaky content <10%

• Hydraulic clearing system, iron protection, reducing unexpected downtime

• Wear parts life extended by 30%, reducing per-ton production costs

• Particularly suitable for high-grade aggregates for highways, high-speed railways, etc.

Grading Capacity: 0-5mm (manufactured sand), 5-10mm (fine aggregate), 10-20mm (medium aggregate), 20-31.5mm (coarse aggregate)

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Your 10-40TPH Calcium Carbonate Plant Is Taking Off——Is Your Vertical Mill Ready for the Ethiopian Highland’s Challenge?

Can a Mobile Coal Crusher Really Survive Indonesia’s Rainy Season While Delivering 200 t/h?

Are You Losing Profits Due to Inefficient Rock Crushing? Discover How Henan Baichy’s Advanced Crushers Can Double Your Output and Meet EPA Standards!

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!