What is barite used for?

The unique physical and chemical properties of barite make it widely utilized in various fields such as petroleum exploration, healthcare, construction, and chemical industry.

| Common fields |

Popular applications |

| Oil and Gas Industry |

Used as a weighting agent in drilling fluids to prevent blowouts |

| Medical |

Used as a contrast agent in radiology examinations, such as barium meals |

| Nuclear Industry |

Used as shielding material for protective walls and floorings in nuclear facilities and laboratories |

| Ceramic and Glass Industry |

Used for manufacturing refractory bricks and castables due to its high-temperature resistance and low thermal expansion |

| Automotive Industry |

Used in the production of car brake pads and clutches |

Types of barite grinding machines

1. Which barite grinding equipment should be selected mainly based on the fineness of the barite powder required by the customer?

2. Barite grinding is generally divided into three fineness levels: coarse powder processing (≤100 mesh), fine powder processing (120 mesh-325 mesh) and ultrafine powder processing (400 mesh-800 mesh).

3. Common types of barite grinding machines include ball mills, Raymond mills, ultrafine mills and vertical Roller mills.

Learn more about Baichy's barite grinding machines, including their advantages, wearing parts and equipment maintenance. Feel free to consult

1. Barite Ball Mill

The ideal choice for large-scale barite powder processing plants, the ball mill boasts robust grinding capabilities suitable for continuous operation.

About of ball mill:

Barite ball mill is a highly efficient ore grinding equipment, mainly used to finely grind barite ore balls to make them easier to extract.

Advantages of barite ball mill

- • Its production capacity can range from 0.2-300 t/h. Specifically, some large barite ball mill equipment, such as Ф5500×8500 model equipment, can reach a processing capacity of 148~615t/h.

- • There are many options. Barite ball mills can be divided into various types according to different grinding methods and processing volumes, such as dry ball mills, wet ball mills, intermittent ball mills, continuous ball mills, etc.

- • Grinding ball material options include steel, ceramics, manganese alloys, etc., ensuring excellent grinding performance and cost-effectiveness.

- • Grinding is carried out in a closed system, combined with a classifier to avoid dust and noise pollution.

- • Simple structure and easy maintenance.

Wearing parts of ball mill

1. Steel Ball of ball mill

- • Function: As a grinding medium, it impacts and grinds the material.

- • Causes of vulnerability: Long-term friction and collision with the material, resulting in wear and deformation.

- • Material and classification: Steel balls can be divided into cast steel balls and forged steel balls according to their production process. Cast steel balls are suitable for dry grinding operations, and forged steel balls are suitable for wet grinding operations. Under normal circumstances, the diameter of the steel balls of the ball mill is between 20-125mm, and the diameter of the steel balls used in the super-large ball mill can reach 130-150mm.

2. Liner of ball mill

- • Function: Protect the cylinder to prevent the material from directly impacting and wearing the cylinder.

- • Causes of vulnerability: Long-term contact with the material and steel balls, resulting in severe wear.

- • Replacement standard: When the liner wear reaches a certain degree (such as 65% wear or a 72mm long crack), it should be replaced.

Their lifespans depend on the hardness of the grinding material, grinding time, and machine operating conditions. Generally, regular maintenance and care can extend their lifespan. Click here to learn more about the maintenance strategies for ball mills.

Barite ball mills and small barite ball mills for sale. Feel free to consult

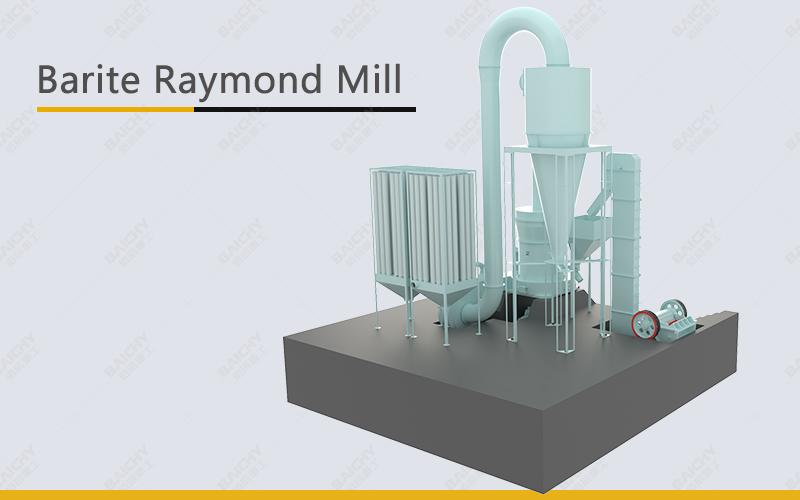

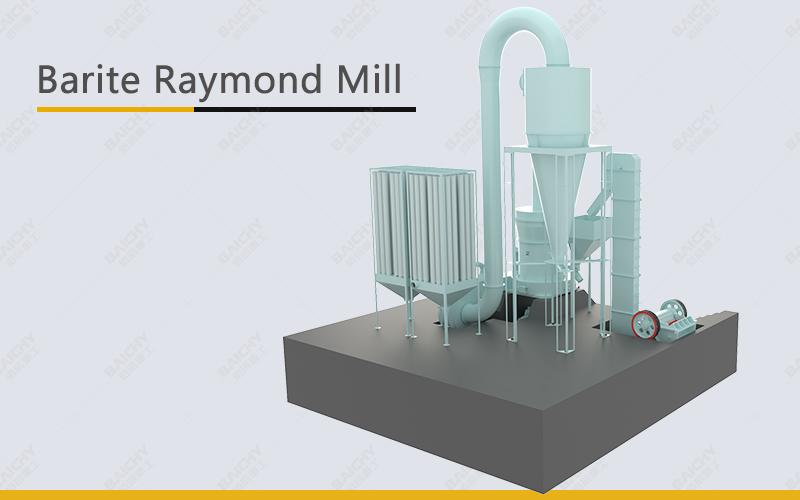

2. Barite Raymond Mill

Barite Raymond mill is a kind of equipment specially used for grinding and processing of mineral materials such as barite.

Advantages of Raymond mill

- • Grinding fineness ranges from 80 mesh to 325 mesh.

- • Low machine cost and low investment.

- • Low energy consumption, easy to achieve high fineness requirements, significant energy saving effect.

- • The equipment adopts a centralized control system, with a high degree of automation and easy operation.

- • The air separation airflow produces less dust during the circulating flow operation, and the operation workshop is clean and pollution-free.

Raymond Mill wearing parts

- • Grinding roller: in direct contact with the material and subject to serious wear. Usually made of alloy steel, alloy carbon steel, ZG65Mn manganese alloy steel, and other wear-resistant materials, the service life ranges from hundreds to thousands of hours.

- • Grinding ring: Paired with the grinding roller to form the grinding zone. Since it is made of the same material as the grinding roller, its service life is similar.

- • Blades: Blades wear out due to material friction over time. The blades are made of steel with good wear resistance and require shorter replacement cycles than grinding rollers and rings.

Click here to learn more about Raymond mill maintenance strategies. Feel free to consult

3. Barite Ultrafine Grinding Mill

Barite Ultrafine Grinding Mill is a kind of equipment specially used to process materials such as barite into ultrafine powder, which meets the high fineness requirements of large-scale production plants.

Advantages of Ultrafine Grinding Mill:

- • Barite Ultrafine Grinding Mill is widely used in the ultrafine powder processing of various minerals, including but not limited to calcium carbonate, gypsum, talc, bentonite, graphite, fluorite, phosphate rock, etc.

- • Suitable for ultrafine powder processing of non-flammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤ 6.

- • The particle size of its fine powder product can be adjusted arbitrarily between 325-3000 mesh, and the output can reach 0.4-4.5 t/h.

- • The use of advanced grinding technology and design enables the equipment to be energy-efficient and reduce energy consumption during operation

Wear parts of Ultrafine Grinding Mill:

- • Grinding roller and grinding ring: directly in contact with the material and subject to huge stress and friction, they are usually made of high-durable materials such as high manganese steel or special alloy steel.

- • Seals and bearings: Exposed to dusty environments and large temperature variations during grinding operations, they require regular maintenance and timely replacement.

The modular design of Baichy machinery allows for seamless parts replacement, minimizing equipment downtime and improving operational efficiency while reducing maintenance costs. Feel free to consult

4. Barite vertical roller mill

Vertical roller mills occupy an important position in modern industrial production with their advanced technology, energy saving, and environmental protection, superior drying performance, simple adjustment, convenient maintenance, high quality of finished products, and wide application fields.

Advantages of vertical roller mills:

- • Taking into account both fineness and production capacity, it can provide 400 mesh barite powder with a maximum production capacity of 420t/h.

- • The grinding part of the vertical mill adopts a flat disc cone roller structure with high efficiency and low energy consumption. It can reduce power consumption by more than 30% compared with the traditional ball milling process, and even achieve a 40-50% energy-saving effect in some cases.

- • It integrates grinding, drying, and powder selection, all of which are completed under negative pressure inside the mill. The equipment has good sealing performance and low dust pollution, which meets the environmental protection requirements of modern industrial production.

- • The vertical mill is suitable for grinding high-moisture materials and can dry materials with a water content of up to 30%. The circulating air heat utilization rate is high, which can meet the requirements of materials with different humidity.

Wearing parts of vertical roller mill:

- • Grinding roller: The heart of the vertical roller mill, the grinding rollers (usually 2-4) are distributed on the grinding disc, usually made of materials such as cast steel, alloy steel, or ceramic coating to withstand the grinding force.

- • Grinding disc: The grinding disc, also known as the grinding stone, is used to grind materials and is usually made of cast steel or cast iron.

- • Separation blade: It plays a vital role in the material classification process and withstands long-term material erosion and wear.

Choosing the right barite grinding mill for your plant!

| Equipment |

Ball Mill |

Raymond Mill |

Ultralfine Mill |

Vertical Roller Mill |

| Feed Size |

≤25 mm |

≤30 mm |

≤40 mm |

≤55 mm |

| Output Size |

20–200 mesh |

80–325 mesh |

80–800 mesh |

20–400 mesh |

| Capacity |

0.65–615 t/h |

8–176 t/shift (8 hours) |

0.4–40 t/h |

2–420 t/h |

| Price |

High |

Low |

Low |

High |

Baichy Machinery will provide customized services according to customer needs and solve customer needs in one stop. Baichy's engineering and technical personnel will provide you with the most suitable barite grinding solution!

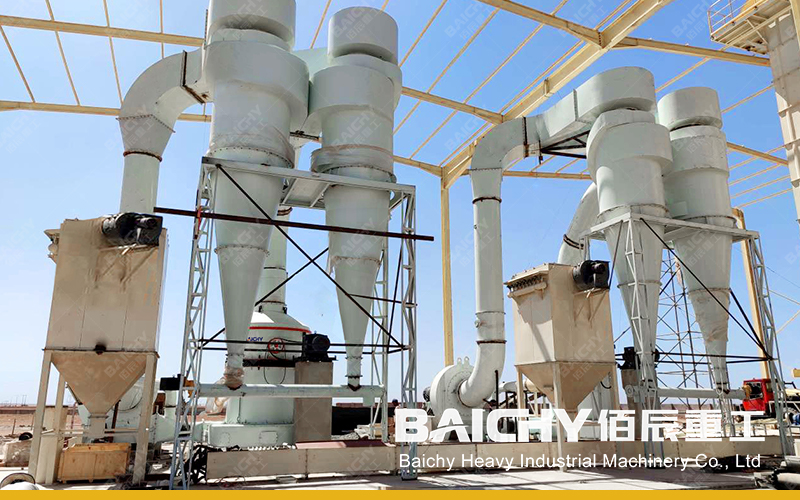

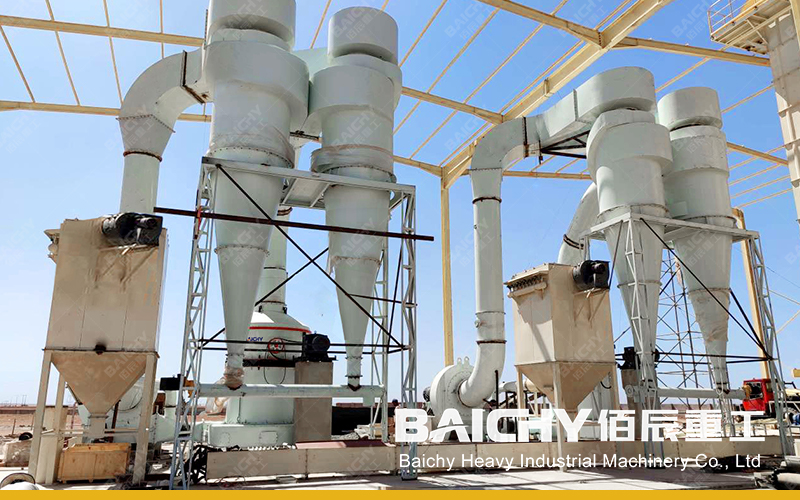

Barite ultrafine powder grinding plant in Nigeria

- Output:13 T/H

- Grinding Equipment:4119 Raymond Mill

- Finished barite powder: 325 mesh

- Customer feedback: Baichy Machinery Raymond Grinding Mill has high grinding efficiency, modern powder selection technology, reliable operation, and a better automatic control system.

Barite powder grinding plant in Morocco

- Output: 80 T/H

- Grinding machine: Ф2700×4500 Ball Mill

- Finished barite powder: 100 mesh

- Customer feedback: The cooperation with Baichy Machinery is very good this time. Before designing for us, we specially arranged for professional technicians to visit the site to provide us with a suitable production plan. The equipment runs stably in production. The purity and fineness of the finished barite powder meet the production requirements.