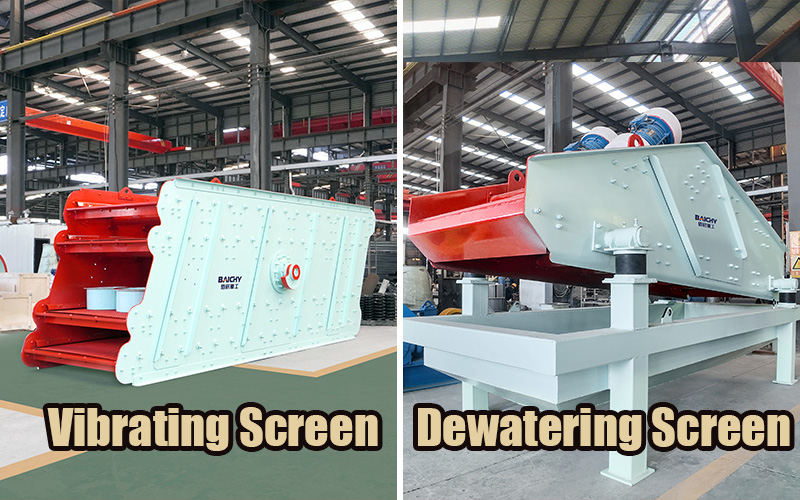

In mining processing production lines, screening equipment is a crucial component. Many people easily confuse vibrating screens and dewatering screens, although they look similar and both operate through vibration, their core functions and application goals are vastly different. Choosing the wrong equipment can, at best, affect production efficiency, and at worst, lead to substandard product quality.

Today, we'll thoroughly understand the differences between vibrating screens and dewatering screens in mining applications.

I. Core Functions: Screening and Grading vs. Solid-Liquid Separation

This is the fundamental difference between the two.

• Vibrating Screen: Its core tasks are screening and grading.

◦ Goal: To separate materials into several groups of different particle sizes based on particle size. For example, separating crushed ore into products of different specifications such as 0-5mm, 5-10mm, and 10-20mm.

◦ Process: The material moves on the screen surface. Particles smaller than the screen openings pass through and fall, while particles larger than the openings remain on the screen and continue moving forward, thus achieving grading.

• Dewatering Screen: The core tasks are dewatering and demedium removal.

◦ Objective: To separate solids and liquids in slurry materials, aiming to reduce the material's moisture content (increase dryness) or recover media from the washing process (such as heavy media separation).

◦ Process: A slurry containing a large amount of water is fed onto the screen surface. Under vibration, the water is separated and discharged through the fine screen openings, while solid particles are discharged as oversize, achieving dewatering.

II. Structure and Design: Optimized for Different Objectives

Different functions directly lead to differences in structure.

• Screen Structure:

◦ Vibrating Screen: Larger screen openings with various shapes (square, round, elongated slots). The screen plate material is wear-resistant, primarily bearing the impact of blocky or granular materials.

◦ Dewatering Screen: Screen openings are typically very fine (e.g., 0.25mm, 0.5mm), mostly elongated slots, designed to prevent fine solid particles from passing through as much as possible, allowing only water to flow. The screen surface is often made of wear-resistant and anti-clogging materials such as polyurethane.

• Screen Inclination Angle:

◦ Vibrating Screen: Relatively large inclination angle to allow materials to be conveyed forward quickly by gravity and vibration, increasing throughput.

◦ Dewatering Screen: Smaller screen inclination angle, even horizontal or negative (upward tilt). This is to increase the residence time of materials on the screen surface, allowing water more time to escape.

• Vibration Trajectory:

◦ Vibrating Screen: Various vibration modes (circular, linear, elliptical) primarily promote material projection, stratification, and screening.

◦ Dewatering Screen: Typically uses linear vibration and is equipped with a high-frequency, low-amplitude vibrating motor. This vibration effectively breaks the surface tension of water, making it easier for water to separate from solids and conveying solid materials forward.

III. Comparison of Mining Application Scenarios

| Features | Vibrating Screen | Dewatering Screen |

| Main Functions | Screening, Grading, Impurity Removal | Dewatering, Desliming, Demediuming, Tailings Dry Discharge |

| Processed Materials | Dry or low-moisture materials | Slurry, wet material, mineral slurry |

| Discharge State | Dry/moist solid particles of different sizes | Relatively dry solid material + separated water |

Typical Applications: Particle size classification after primary/secondary crushing of ore; size screening of finished ore. Dewatering of sand and gravel after washing; dewatering and dry discharge of concentrate/tailings in concentrators; heavy media recovery.

In short:

• When you want to ask How big is this ore?, use a vibrating screen to group it by size.

• When you want to ask How dry is this wet ore?, use a dewatering screen to remove its moisture content.

IV. How to Choose the Right Screen?

The key to selection lies in your process objectives:

1. If the goal is to obtain a product of a specific particle size (e.g., producing aggregates of different sizes for construction), choose a vibrating screen.

2. If the goal is to reduce the moisture content of materials (e.g., dewatering concentrates for easier transport, or dry-piling tailings for environmental and water-saving purposes), choose a dewatering screen.

On some production lines, vibrating screens and dewatering screens work together. For example, ore is first classified by a vibrating screen, some of the classified product may need to be washed, and the washed slurry is then fed to a dewatering screen for further dewatering.

In short, a vibrating screen is a classifier of material size, while a dewatering screen is a dewatering machine for solid-liquid mixtures. Although both are called screens, their design philosophies and application areas are quite different. A thorough understanding of these differences can help mining professionals select equipment more scientifically, optimize process flows, and thus achieve production goals of improved quality and efficiency, energy conservation, and environmental protection.