In mining crushing production lines, cone crushers are undoubtedly the mainstay. And we industry veterans know that what determines the continuous, efficient, and stable operation of a cone crusher is often not its indestructible manganese steel liner, but rather its intricate internal hydraulic system. It acts as the equipment's "heart" (providing power) and "nerves" (control and regulation); if it "malfunctions," the entire production line may face shutdown.

Today, we won't discuss abstract theories, but rather take a practical approach to systematically outline the core maintenance points of a cone crusher's hydraulic system. This strategy aims to help you minimize unplanned downtime, significantly extend equipment life, and ultimately improve your return on investment.

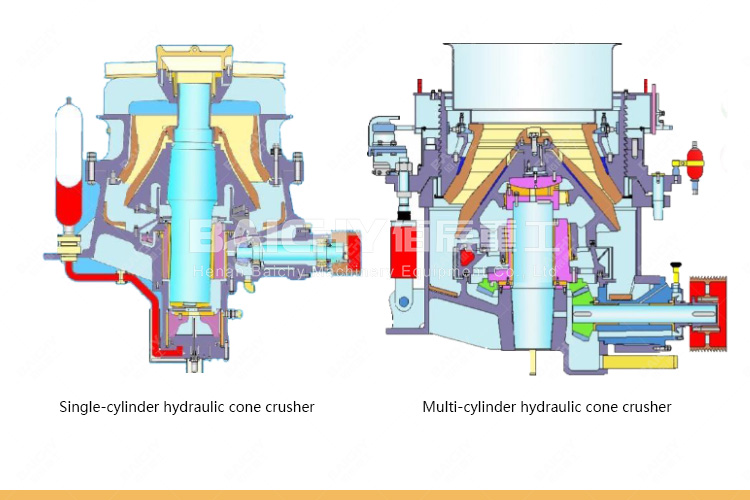

I. The Core Role of the Hydraulic System in a Cone Crusher

Before delving into maintenance, we must understand what we are maintaining. The hydraulic system of a cone crusher primarily undertakes three missions:

1. Adjusting the discharge opening: By raising and lowering the hydraulic cylinder, the position of the moving cone is precisely controlled, thereby adjusting the size of the discharge opening. This is crucial for ensuring product particle size.

2. Overload Protection and Cavity Clearing: When an uncrushable object (such as an iron block) enters the crushing chamber, the system pressure surges. The hydraulic system raises the fixed cone to expel the object, then quickly resets, protecting the core components of the equipment from damage.

3. Providing Locking Force: The hydraulic system provides a significant locking force to the adjusting ring and fixed cone, ensuring the crushing operation takes place within a stable mechanical structure.

Understanding these three points will help you understand that even a minor malfunction in the hydraulic system can directly impact production efficiency and safety.

II. Prevention is Better than Cure: The "Golden Rule" of Daily Maintenance

Daily maintenance is the lowest-cost and most effective investment. Please include the following in your daily inspection checklist:

• Hydraulic Oil Level Check: Before starting the machine each day, check the oil level in the tank with the equipment stationary, ensuring it is between the upper and lower marks on the dipstick. Too low an oil level can cause the pump to cavitate and burn out; too high an oil level can lead to abnormally high temperatures.

• Oil Temperature Monitoring: The ideal operating temperature for hydraulic oil is typically between 30-60℃. Sustained high temperatures (above 80°C) accelerate oil oxidation and deterioration, and cause seal aging. Check for blockages in the cooler and ensure the fan is operating normally.

• Leak Inspection: Carefully inspect all hydraulic lines, joints, and cylinder seals for oil seepage or leakage. Even minor leaks indicate worn seals or loose joints.

• Abnormal Noises and Vibrations: Listen for harsh noises from the hydraulic pump during operation; this could be a sign of air intake or pump damage. Observe the system for abnormal vibrations.

III. Deep Maintenance: A Key Node in Periodic

Maintenance Routine maintenance is like a "check-up," while periodic maintenance is like "deep treatment."

• Regular Hydraulic Oil Change: This is the most important maintenance item! It is generally recommended to change the oil every 2000-3000 hours of operation or annually (depending on the working environment and oil quality test results). Remember: When changing the oil, the oil tank must be thoroughly cleaned, and the suction and return oil filter elements must be replaced simultaneously. Use the oil brand and viscosity grade recommended by the equipment manufacturer.

• Filter Replacement: The suction filter protects the hydraulic pump, while the return filter cleans the system fluid. Replacement must be strictly performed according to the time intervals specified in the maintenance manual; never exceed the recommended service life.

• Seal Inspection and Replacement: During major equipment overhauls or replacement of major hydraulic components, aged O-rings and seals should be inspected and replaced simultaneously to avoid serious damage.

• Accumulator Inspection: The nitrogen pressure in the accumulator is crucial for the iron overload protection function. Its pre-charge pressure should be checked regularly (e.g., every six months) to ensure it is within the specified range.

IV. Common Fault Warning Signals and Quick Diagnosis

Your hydraulic system may be sending out distress signals when the following occurs:

• Discharge port automatically widens: This is usually caused by insufficient locking cylinder pressure or loss of nitrogen pressure in the accumulator.

• Slow or no movement: Check the motor rotation direction, whether the hydraulic pump is working properly, whether the oil level is too low, and whether the filter is clogged.

• Abnormal System Pressure: Failure to build pressure may be due to a faulty relief valve or internal pump leakage; excessively high and unstable pressure may indicate a stuck or blocked relief valve.

• Overheating Oil: In addition to cooler issues, check if the hydraulic oil has deteriorated and if the system pressure setting is too high, leading to excessive overflow loss.

Careful maintenance of the cone crusher's hydraulic system, while seemingly a continuous investment, is actually the most productive investment with the highest return. It not only reduces downtime and the risk of major overhauls, but also provides a solid guarantee for equipment uptime, production efficiency, and overall benefits.