In numerous industrial sectors such as ore processing, building materials production, metallurgy, and chemicals, grinding is a core process determining the final product quality and production efficiency. Raymond mills, as the mainstay of industrial grinding production lines, are widely used in the grinding of non-metallic minerals such as marble, limestone, and calcite due to their compact structure, uniform powder production, environmental friendliness, and high efficiency.

However, faced with a dazzling array of equipment and models on the market, many customers often feel overwhelmed when making a purchase: How to interpret the technical parameters? Which model is most suitable for my raw materials? How to rationally allocate the investment budget?

As a mining machinery manufacturing expert with over 30 years of industry experience, Baichy Heavy Industry understands your concerns. This article will systematically outline the key steps in equipment selection to help you make the wisest decision.

Step 1: In-depth Analysis of Your Needs – Clarifying Grinding Objectives

Before selecting equipment, a clear self-assessment is the first step to success. Please be sure to clarify the following points:

1. Raw Material Characteristics Analysis:

◦ Physical Properties: What are the Mohs hardness, moisture content, viscosity, and impurity content of the material? High-hardness materials (such as quartz) require equipment with stronger wear resistance and grinding power; high-moisture or viscous materials require consideration of the equipment's anti-clogging design and suitability for dry/wet grinding.

◦ Feed and Finished Product Requirements: What is the initial particle size of your raw material? What is the desired finished product fineness (D97)? What are the target hourly/annual output requirements? These are the most direct factors determining the equipment model and power.

2. Production Environment and Process Considerations:

◦ Space Layout: Is it a fixed production line or mobile equipment? What are the limitations on plant space and height? Although Raymond mills have a small footprint, they still require proper planning.

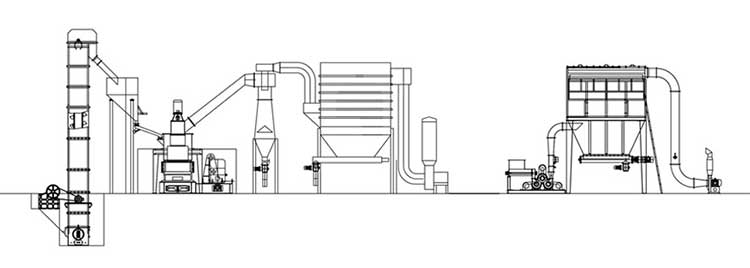

◦ Environmental Standards: What are the requirements for dust and noise control? Baichy's complete grinding system is equipped with a high-efficiency pulse dust collector to ensure that production meets green environmental protection standards.

Step Two: Understanding Equipment Technical Parameters – Understanding the Manufacturer's Language

With numerous manufacturers on the market, technical parameters are the "common language" for objectively comparing different equipment. When consulting, please focus on the following key parameters:

• Grinding ring diameter and rotation speed: This directly affects grinding capacity and efficiency.

• Maximum feed particle size: Ensure your raw materials can smoothly enter the equipment.

• Finished product particle size range: Confirm whether the equipment can consistently achieve your required fineness (e.g., 80-400 mesh).

• Processing capacity (output): This is crucial for matching your production plan. Inquire about the actual output at the target fineness, not the maximum value.

• Main unit power: This relates to equipment energy consumption and operating costs.

Baichy Tip: Different manufacturers use different model naming rules; do not make a decision solely based on the model number. Always request a detailed technical parameter table for comparison, or directly provide your raw material sample for free grinding testing. This is the most reliable verification method.

Step 3: Matching Raw Materials and Equipment Performance – Tailor-made Solutions

Different grinding equipment has its own areas of expertise. Taking Baichy's product line as an example:

• For medium-hardness materials such as marble, limestone, and feldspar, Raymond mills and YGM grinding mills are cost-effective and efficient choices.

• For finer powders (e.g., 800 mesh and above), vertical roller mills or HGM micro-powder grinding mills are more suitable.

• For high-moisture materials, a drying step may be necessary before grinding, or our three-cylinder dryer can be used in conjunction with the mill.

Core principle: There is no "best" equipment, only the "most suitable" equipment. Equipment that efficiently processes your specific materials is far more valuable than an expensive but overkill device.

Step Four: Weighing Investment and Overall Benefits – Looking at Long-Term Value

The purchase cost of equipment is just the tip of the iceberg; wise investors focus on the overall benefits throughout the entire lifecycle.

• Initial Investment: Includes the price of the equipment itself, transportation, and installation costs.

• Operating Costs: Energy consumption is a major long-term expense. Highly efficient and energy-saving designs can save businesses significant amounts on electricity bills.

• Maintenance Costs: The replacement cycle and price of wear parts (such as grinding rollers and grinding rings) are crucial. Baichy equipment is manufactured with high-quality wear-resistant materials, ensuring a long service life. We also guarantee the supply of original spare parts, effectively controlling your later maintenance costs.

• After-Sales Service: Can the manufacturer provide timely installation guidance, technical support, and repair services? This directly affects the continuity and stability of production.

Baichy Heavy Industry: Your Trusted Grinding Solution Partner

Choosing Baichy means you get more than just a piece of equipment; you get a complete solution:

• Over 30 Years of Professional Experience: We focus on the R&D and manufacturing of mining machinery, deeply understanding the pain points of users in various industries.

• Free Testing and Solution Design: We welcome you to send 50-100 kg of raw material samples to our laboratory. We will conduct free grinding tests and provide detailed capacity reports and customized production line design solutions.

• Comprehensive Technical Support: From project planning and equipment installation and commissioning to operator training, we provide one-stop service to ensure smooth project commissioning.

• High Cost-Effectiveness and Global Service Network: We are committed to providing customers with products that maximize value. Our equipment is sold to more than 150 countries and regions worldwide, and we have established a comprehensive after-sales service system.

Act Now!

If you are still hesitant about how to choose grinding equipment, please contact the professional team at Baichy Heavy Industry immediately. Let us leverage our extensive experience to tailor the most economical and efficient grinding solution for you.

Free Consultation Hotline: +86 15093222637

Official Website: www.baichychina.com

Email: [email protected]