Ball Mill

Ball mill overview

Ball mill is an industrial equipment used for crushing, grinding or mixing solid materials. It is widely used in mining, building materials, chemical industry, metallurgy and other fields. Its core principle is to crush the material to the required fineness through the impact and friction of the grinding media (such as steel balls, ceramic balls, etc.) in the cylinder.

The ball mill has a low speed and is very suitable for grinding hard and wear-resistant materials such as quartz sand and zircon sand, as well as soft minerals such as calcium carbonate and kaolin. It is widely used in mineral processing, building materials, chemical industry and other industries.

cement ball mill

Features of ball mill

• Wide range of applications

It can handle materials with different hardness (such as ore, coal, cement raw materials, etc.), and both dry and wet grinding are possible.

• High crushing efficiency

By adjusting the size and speed of the grinding media, coarse crushing to ultra-fine crushing can be achieved.

• Simple structure and stable operation

The main body consists of a rotating cylinder, a transmission device, a feeding and discharging device, etc., which is easy to maintain.

Closed operation can be performed to prevent dust pollution, suitable for the treatment of harmful or easily oxidizable materials.

• Disadvantages

High energy consumption, high noise during operation, grinding media is easy to wear and needs to be replaced regularly.

Working Principle of Ball Mill

Working principle of ball mill

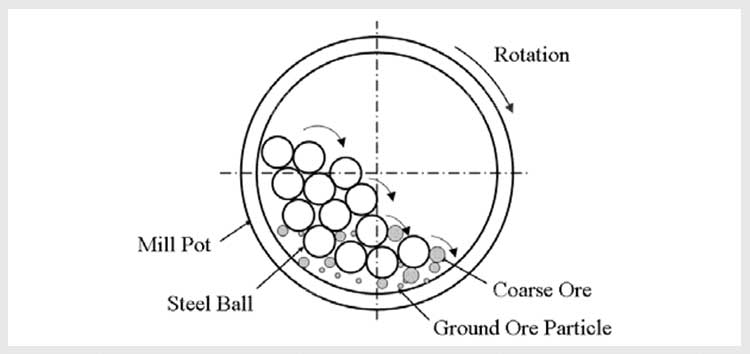

The working principle of ball mill is based on the synergistic effect of centrifugal force, impact force and friction force:

• Cylinder rotation

The motor drives the cylinder to rotate through the reducer, and the speed is usually 60%~80% of the critical speed (critical speed refers to the speed at which the grinding media begins to centrifuge).

• Grinding media movement

The grinding media (steel balls, etc.) in the cylinder are lifted to a certain height by centrifugal force, and then fall in a parabolic trajectory, causing impact and crushing of the material.

• Friction and grinding

The material is squeezed and rubbed during the rolling and sliding process of the medium, and gradually refined.

• Classification and discharge

Fine particles are discharged through the discharge device, and coarse particles continue to remain in the cylinder for grinding (some ball mills are equipped with a classification device).

Ball mill customer site

Classification of ball mills

• By grinding method

Dry ball mill: suitable for moisture-sensitive materials.

Wet ball mill: grinding with water, suitable for subsequent flotation or slurry preparation.

• By structure

Horizontal ball mill: the most common, with the cylinder placed horizontally.

Vertical ball mill: saves space and is used for ultra-fine grinding.

• By discharge method

Overflow type: the material is discharged through overflow, suitable for fine grinding.

Grate type: forced discharge through the sieve plate, with a larger processing capacity.

Application scenarios of ball mills

• Mining: ore crushing in the beneficiation process of gold, copper, iron ore, etc.

• Cement industry: grinding of limestone and clinker.

• Chemical industry: fine grinding of pigments, coatings, and ceramic raw materials.

• Laboratory: uniform mixing of small batches of materials or preparation of nanomaterials.

Key parameters of ball mills

• Diameter and length of the cylinder: determine the processing capacity and grinding efficiency.

• Filling rate: the proportion of grinding media to the cylinder volume (usually 30%~50%).

• Speed: affects the movement of the media (cascading, throwing or centrifugal).